ISBM Machine Portfolio

From compact to high-output models — engineered for PET, PP, and beyond.

Y50-V3-EV

YS150-V4 (EV)

YS200-V4 (B)

YS250-V4 (B)

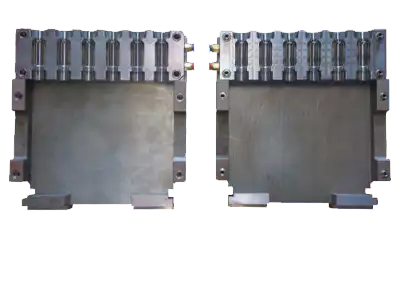

Injection Mold

YS280-V6

YS650-V4

Precision Engineered ISBM Machines

Ever-power Machinery Co., Ltd

Ever-Power is a Singapore-based innovator specializing in One-step Injection Stretch Blow Moulding Machines (ISBM machines). With over 20 years of expertise, we design and manufacture high-performance, energy-efficient ISBM systems for PET, PP, and other advanced materials—trusted globally for bottles in food, beverage, pharmaceutical, and cosmetic applications.

Applications of Our One-Step ISBM Machines

Personal & Household Care Bottles

Water & Beverage Bottles

Infant Feeding & Nutrition Containers

Pharmaceutical & Supplement Packaging

Cosmetic & Fragrance Packaging

Food Jars & Wide-Mouth Containers

Edible Oil & Condiment Bottles

Custom & Complex-Shaped Containers

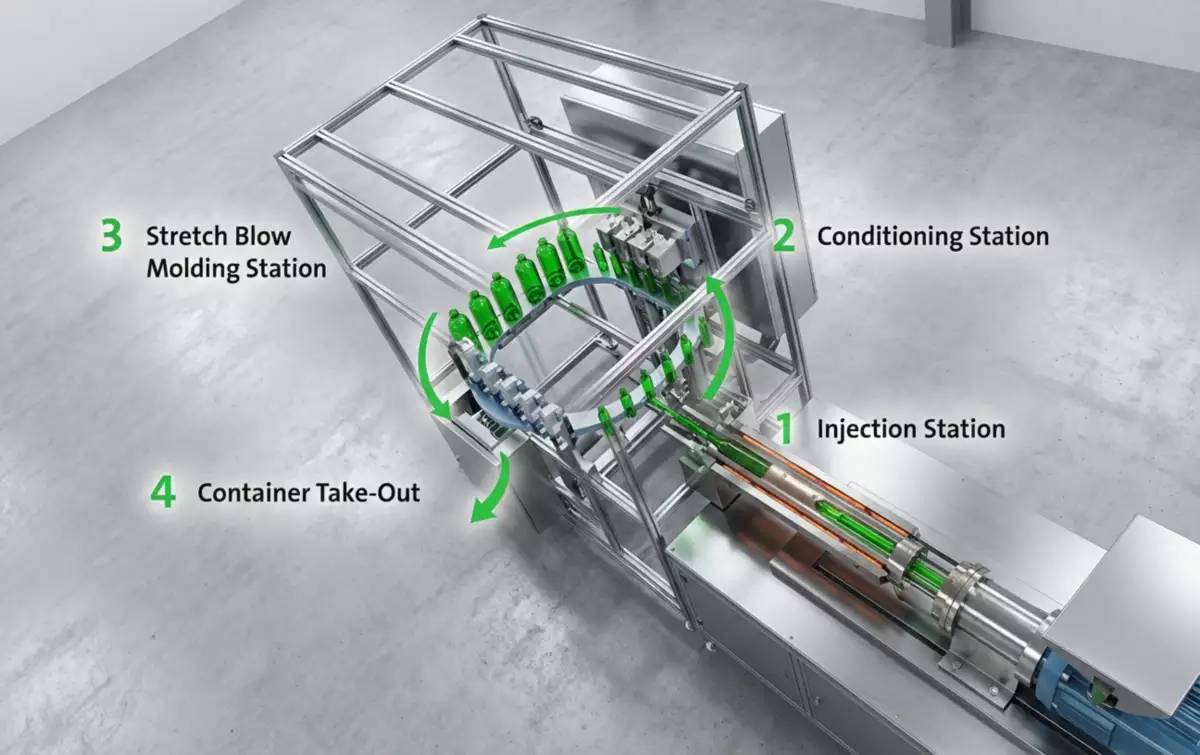

What Is a One-Step ISBM Machine

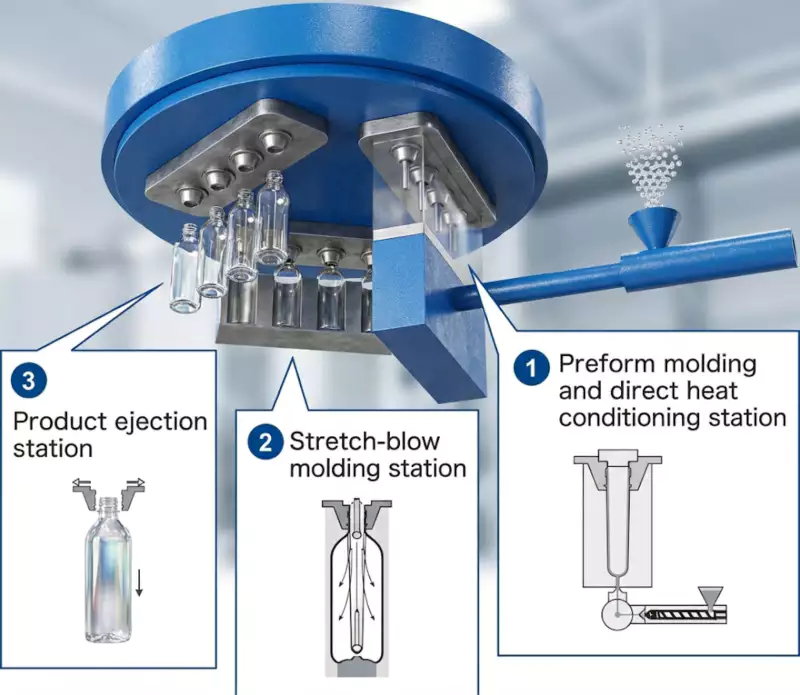

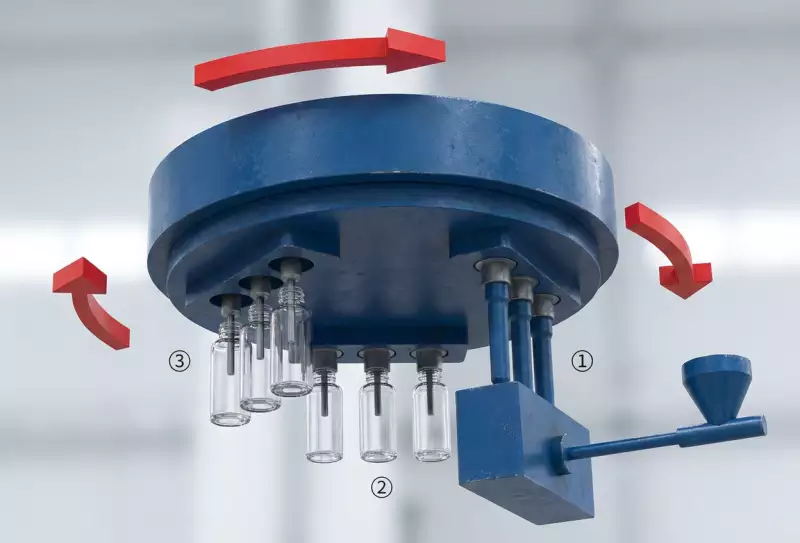

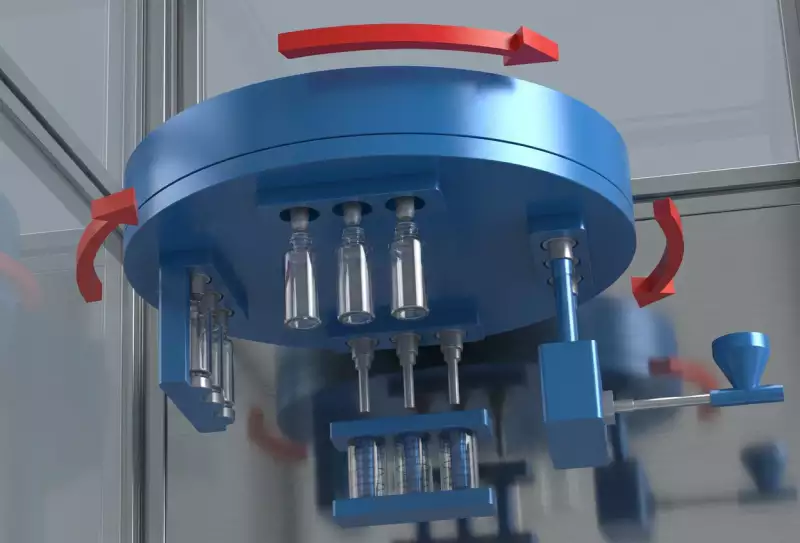

The One-Step Injection Stretch Blow Moulding (ISBM) process is a high-efficiency, integrated plastic container forming technology that completes injection, stretching, and blow moulding in a single machine — all in one continuous cycle.

Unlike traditional two-step systems that require separate preform production and reheating, the one-step ISBM machine directly transforms raw plastic pellets into finished bottles with exceptional precision, uniform wall thickness, and superior product stability. This seamless integration eliminates intermediate steps, reduces energy consumption, and minimizes material waste — making it ideal for producing high-value containers

3-Station ISBM

4-Station ISBM

Injection

Tail Cutting

& Heat Preservation

Stretch Blow Moulding

Bottle Take-out

Core Advantages

Energy Efficient

Utilizes residual heat from the injection process for blowing, eliminating secondary heating. This one-step approach reduces energy consumption by approximately 40%.

Excellent Performance

Stretch-induced molecular orientation significantly enhances the bottle's compression resistance, barrier properties, and optical transparency.

High Precision & Stability

Full-process automation minimizes human error, ensuring consistent dimensional accuracy. Ideal for high-standard mass production.

High Material Utilization

Flash-free molding technology significantly reduces waste material. This eco-friendly process lowers raw material costs while protecting the environment.

Operational Efficiency

Designed for maximum ROI with a compact footprint, low labor requirements, and low energy consumption, offering a highly stable production solution.

Versatile Design Capability

Capable of producing a wide range of irregular and complex bottle shapes (e.g., handle bottles) with premium aesthetics to meet diverse market needs.

Benchmarking Top Japanese Standards with Seamless Flexibility

Our machine rivals the performance and precision of international giants like Nissei ASB and Aoki. Designed with asset preservation in mind, it allows you to utilize existing tooling without modifications.

- Rivals ASB & Aoki Quality

- ASB Mold Compatible

- Save Tooling Cost

- Easy Replacement

Use them directly on our machine.

One-Step VS. Two-Step Technic

| Comparison Metrics | One-Stage (ISBM) | Two-Stage Process |

|---|---|---|

|

Process Principle

|

Latent Heat Utilization "Hot Preform" method: Uses residual heat from injection for blowing. No secondary heating required. | Reheating Required "Cold Preform" method: Preforms must be cooled, stored, and then fully reheated before blowing. |

|

Energy Efficiency

|

~40% Energy Savings Eliminates the energy-intensive reheating process, significantly reducing electricity costs. | High Consumption Wastes energy through the "cool down & reheat" cycle. Requires heating tunnel energy. |

|

Aesthetic Quality

|

Flawless Surface Zero contact/friction. Bottles are crystal clear with no scratches. Ideal for high-end cosmetics. | Surface Scratches Preforms suffer friction marks during bulk transport, tumbling, and loading. |

|

Shape Versatility

|

High Flexibility Capable of producing **handle bottles**, irregular shapes, and wide-mouth jars. | Limited Shapes Mostly restricted to standard symmetrical round/square bottles. Difficult for handle bottles. |

|

Space Requirement

|

Compact Footprint All-in-one machine. No need for preform warehouse or unscrambling equipment. Space usage: **Little**. | Large Footprint Requires 2 machines (Injection + Blow) plus large warehouse space for preform inventory. |

|

Logistics & Storage

|

"Resin-to-Bottle" Streamlined workflow. No preform inventory management or aging time required. | Complex Logistics Complex management of preform stock, classification, and internal transport. |

|

Labor & Maintenance

|

Low Labor Cost Full automation reduces human error. Requires fewer operators. | Higher Labor Cost Requires operators for two separate machines plus material handling staff. |

|

Hygiene & Safety

|

Contamination-Free Closed-loop process prevents dust/static. Perfect for Pharma & Food grade products. | Hygiene Risks Open storage allows preforms to absorb moisture and static dust. |

Bottle Sample Display

Global Success Stories

Proven Performance Across Industries & Continents

Crucial: Client reused existing ASB-compatible mold base, saving ~$38K tooling costs.

Result: 9.2s cycle time, zero haze, wall thickness variation <±0.08mm.

Performance: Running at 11,200 bph with <0.3% rejection.

Modbus TCP integration successful. Client ordered a second unit proving scalability.

Processing PP resin at 230°C with precise thermal control (no degradation).

Passed FDA audit on the first attempt.

Reliability: Achieved 1.5m drop-test survival.

Saved $120K/year in operational expenses.

Frequently Asked Questions (FAQ)

What materials does your one-step ISBM machine support? Can it process premium resins like PP, PETG, or PC?

A: Yes. As stated on page 1 of the brochure, Henggang’s one-step injection stretch blow molding machines are fully compatible with a wide range of materials, including PET, PETG, PC, PCTG, and PP. These are ideal for high-performance applications in cosmetics, food, and pharmaceutical packaging. Our machines feature an integrated temperature control system and nano far-infrared energy-saving heating rings to ensure optimal processing conditions for each material—delivering excellent clarity, mechanical strength, and safety.

Are your machines compatible with molds from Japanese brands like ASB or AOKI? Do we need to invest in new tooling?

- HGY150-V4 / HGYS150-V4-EV series: explicitly noted as “compatible with ASB-12M molds”

- HGY200-V4-B series: specified as “compatible with AOKI 250-series molds”

Is the one-step process really more energy-efficient than two-step? How much can we save?

“No secondary reheating of preforms is required; the heat from injection is directly used for blowing, reducing energy consumption by approximately 40%.”

Who are your reference customers? How reliable are your machines in long-term operation?

C’ESTBON (Master Kong), HAITIAN, Luhua, Blue Moon, Liby, Estée Lauder, Walmart, and Shanliang Eye Drops

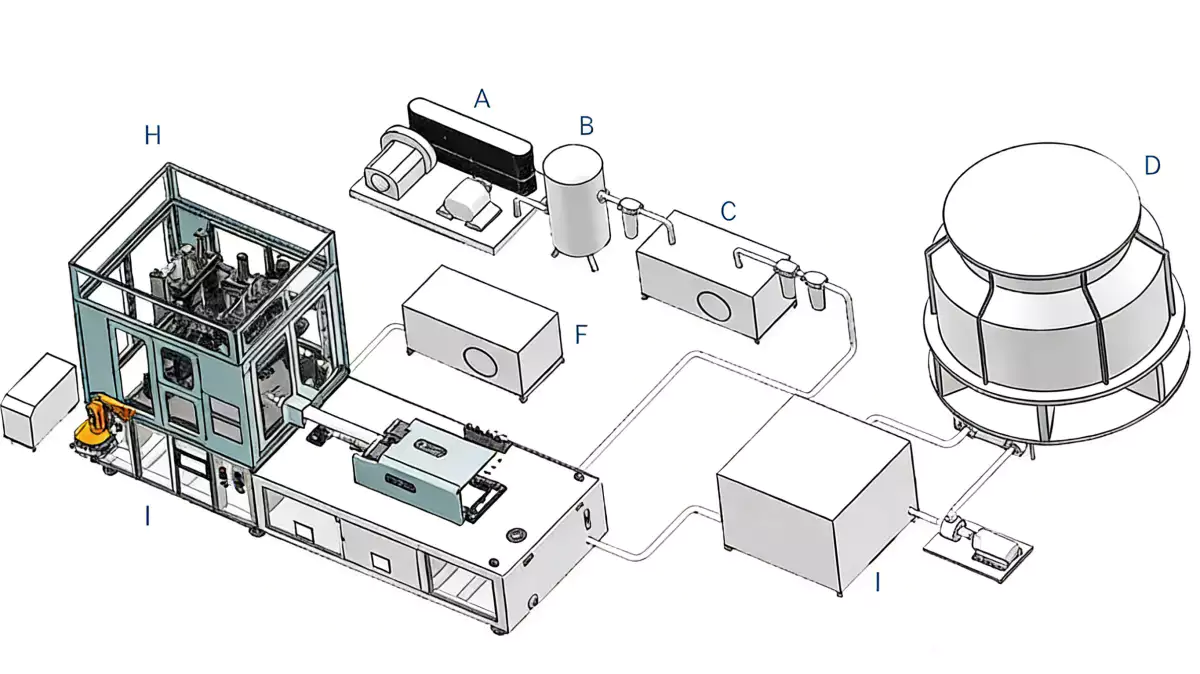

Machine Layout Reference

Service Brands

Product sales have covered every province and city in China and many countries around the world.