Description

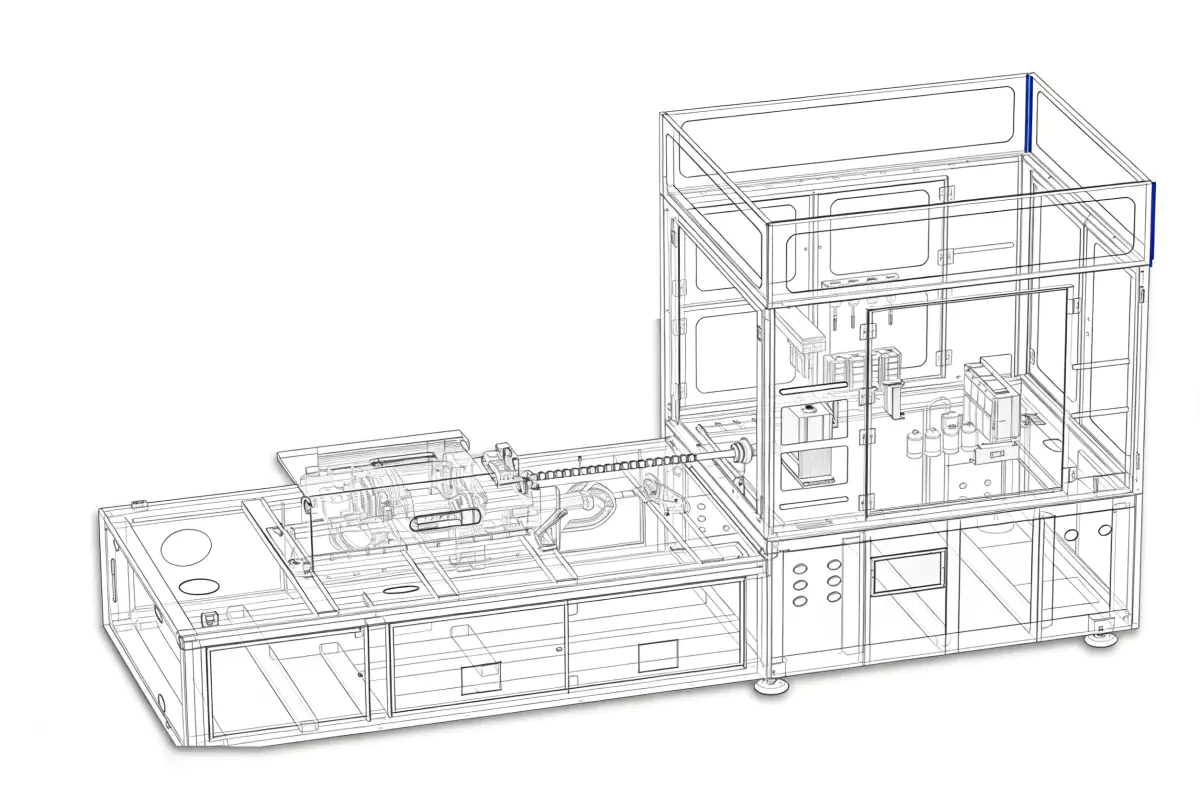

One Step Blow Molding Machine HGY50-V3-EV (3-Station) | Precision ISBM Technology

Core Technology Speed Read

The HGY50-V3-EV is a state-of-the-art One Step Injection Stretch Blow Molding Machine designed for high-precision manufacturing. Operating on a fully electric servo platform, this 3-station unit integrates injection, stretching, and blowing into a seamless continuous process. It is engineered to process a wide versatility of materials including PET, PETG, and PC, making it the ideal solution for premium cosmetic and pharmaceutical packaging. With a compact footprint of just 3.8m x 1.2m, it delivers industrial-grade performance while saving valuable factory floor space.

HGY50-V3-EV Overview: The Efficiency Revolution

The HGY50-V3-EV redefines the standards of the One Step PET Bottle Machine market. By adopting a “One Step” methodology, the machine utilizes the residual heat from the injection phase to perform the stretch blow molding immediately. This eliminates the need for reheating preforms, which directly results in an energy consumption reduction of approximately 40% compared to traditional two-step systems.

Key Advantages at a Glance

- Full Servo Precision: Equipped with 5 sets of servo systems (Inovance/Weichi), ensuring injection and clamping accuracy.

- Surface Perfection: The one-step process prevents preform scuffing, ensuring high transparency and barrier properties for the final bottle.

- High Efficiency: Complete automation reduces human error and labor costs while maximizing material utilization.

Technical Specifications: HGY50-V3-EV

Detailed engineering data for our 3-station One Step Injection Molding Machine, optimized for mobile viewing.

1. Machine Parameters

| Item | Specification |

|---|---|

| Model Name | HGY50-V3-EV (3-Station) |

| Theoretical Injection Capacity | 239 cm³ (Standard 40mm Screw) |

| Screw Diameter Options | 40mm / 50mm / 55mm |

| Injection Clamping Force | 50 KN |

| Blowing Clamping Force | 100 KN (Single Side) |

| Servo Motor Power | 34.8 KW |

| Heating Power | 10.4 KW |

| Machine Dimensions (L*W*H) | 3800 * 1200 * 2500 mm |

| Machine Weight | 3.5 Tons |

2. Product Capability Specifications

| Cavities | Max Bottle Dia (mm) | Max Neck Dia (mm) | Max Volume (ml) |

|---|---|---|---|

| 1 | 100 | 60 | 2500 |

| 2 | 90 | 38 | 1500 |

| 3 | 62 | 30 | 900 |

| 4 | 45 | 27 | 400 |

Deep Dive: The ISBM Technology Advantage

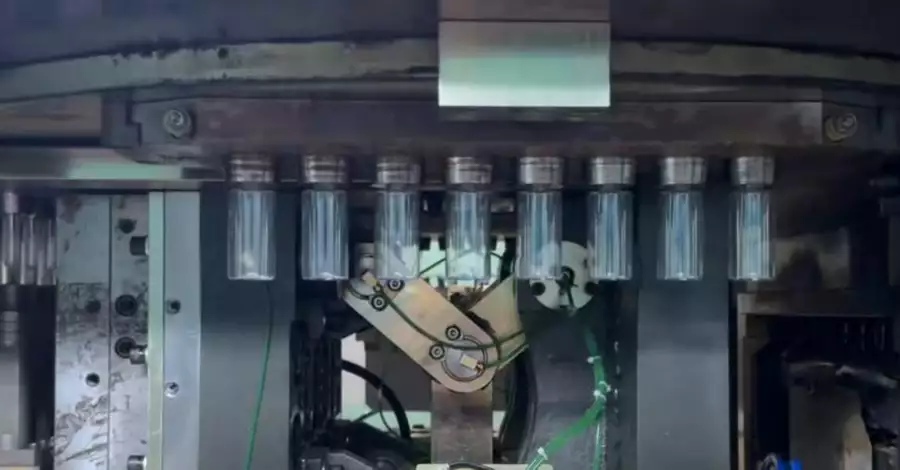

The ISBM Blow Molding Machine process integrated into the HGY50-V3-EV is a highly efficient plastic container molding technique. It is widely adopted for producing high-precision, high-demand hollow plastic products such as baby bottles, water cups, and pharmaceutical vials. The core feature is that the three steps of injection, stretching, and blow molding are completed continuously in the same equipment without intermediate steps.

One-Step Process Flow

Injection of Preform

Tail Cutting & Heat Preservation

Stretch Blow Molding

Bottle Take-out

Why Choose Our HGY50-V3-EV?

- High Material Utilization: Less waste material, environmental protection, and low cost.

- Superior Physical Properties: Stretching makes the material molecules orient, which significantly improves compression resistance, barrier properties, and transparency.

- High Precision: Full process automation control reduces human error, suitable for mass production.

Technology Face-off: One-Step vs. Two-Step

Understanding the difference between One Step Injection Blow Molding and the Two-Step method is crucial for calculating ROI.

| Comparison Dimension | Ever-power One-Step ISBM | Traditional Two-Step Method |

|---|---|---|

| Process Continuity | Continuous (Resin to Bottle) | Discontinuous (Preform Storage Required) |

| Energy Efficiency | High (Saves ~40%) | Lower (Requires Re-heating Preforms) |

| Surface Quality | Flawless (No Scratches) | Risk of Scuffing during Transport |

| Machine Footprint | Compact (One Machine) | Large (Injection + Reheat Blower) |

| Hygiene Level | High (No Human Contact) | Risk of Contamination during Storage |

Industry Applications

The One Step Molding Machine is not just for water bottles. It is the gold standard for industries requiring aesthetic perfection. Explore more specialized solutions in our ISBM Machine category.

Cosmetics & Personal Care

Production of high-end cosmetic bottles using PET/PETG/PCTG with heavy walls and glass-like finishes.

Pharmaceuticals

Ideal for medicine bottles and eye drops, ensuring sterility and compliance with packaging regulations.

Food & Baby Products

Manufacturing of baby bottles and wide-mouth food jars using safe materials like PP, PC, and Tritan.

Global Standards & Competitor Benchmarking

Ever-power machines are engineered to match the technical standards of leading Japanese brands. We use premium components like Yaskawa servo motors (Japan), Parker high-pressure valves (USA), and AirTAC cylinders.

The Ever-power Promise: Our HGY50-V3-EV offers a direct alternative to Japanese machines like ASB-12M, providing compatible mold interfaces and comparable cycle times at a more accessible investment point.

[Southeast Asia] Extreme Humidity Production Research

Operating a One Step Blow Molding Machine in high-humidity environments requires robust dehumidification. The HGY50-V3-EV is designed with an integrated temperature control box that is highly accurate and stable, preventing moisture-related defects in PET processing.

Investment Analysis: Profitability of ISBM

Switching to our One Step Injection Blow Molding system offers significant ROI for medium-sized bottling plants:

- Energy Savings: ~40% reduction in electricity bills due to eliminating the reheating phase.

- Material Savings: High precision control allows for lightweighting without sacrificing strength.

- Space Efficiency: The machine occupies only 3.8 x 1.2 meters, reducing facility rental costs.

Engineers’ FAQ: Common Questions

What materials can the HGY50-V3-EV process?

It handles a wide range including PET, PETG, PC, PCTG, PP, PS, and Tritan.

Is the screw diameter customizable?

Yes, the standard is 40mm, but we offer optional 50mm and 55mm screws depending on shot weight requirements.

What is the total power consumption?

The total power of the machine is 45.2KW, with a heating power of 10.4KW.

Does it support multi-cavity production?

Yes, it supports 1 to 6 cavities depending on bottle size. For example, it can produce 4 cavities of 400ml bottles.

What is the lead time for machine and mold?

We are a professional manufacturer with a complete supply chain. Typical lead time is 60-90 days including mold testing.

Global Case Studies: Field Notes

1. Cosmetic Brand (China): Partnered with major brands like Estee Lauder and Proya, providing machines for high-end lotion bottles.

2. Pharmaceutical (Global): Supplied equipment for “Shanliang Eye Drops” packaging, ensuring sterile and precise neck finishes.

3. Beverage Industry (Vietnam): A water bottling plant used our ISBM Machine to produce 1.5L PET bottles with a 2-cavity setup, maximizing output in a small space.

4. Baby Products (Brazil): Utilized the machine’s capability to process PC/Tritan for durable, heat-resistant baby bottles.

Gallery: Precision in Motion

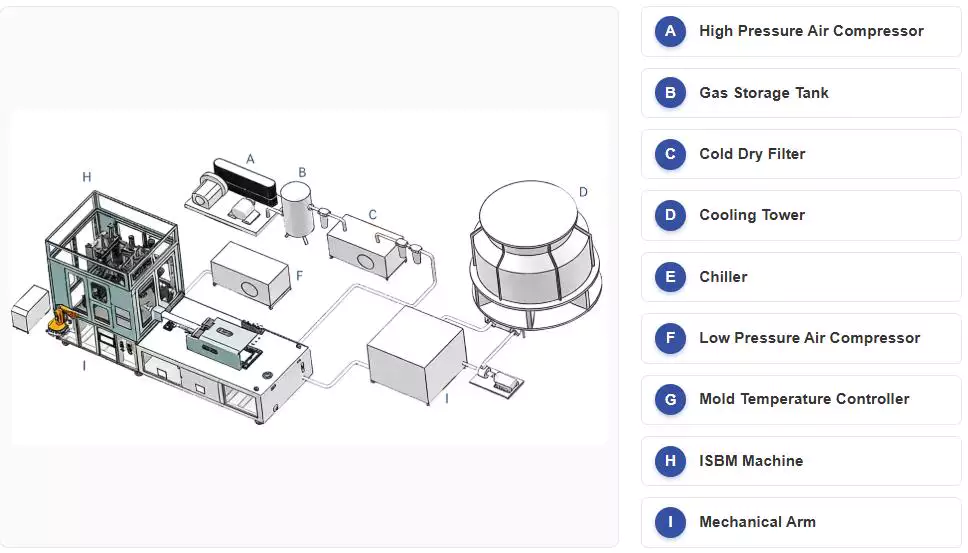

Complete Your Production Line

A pristine blowing process requires contaminant-free air. Enhance your production quality with our industrial-grade Oil-Free Air Compressors, specifically designed to pair with our ISBM units for medical and food-grade applications.

Ready to Upgrade Your Packaging Efficiency?

Contact Ever-power’s engineering team today for a free cycle time calculation and mold design consultation.