Description

One Step Blow Molding Machine (4-Station) HGY150-V4 | Precision ISBM Technology

Core Technology Speed Read: Power System & Selection Essentials

The HGY150-V4 is a flagship 4-station One Step Injection Stretch Blow Molding Machine designed for manufacturers who refuse to compromise between speed and optical clarity. Engineered with a robust 150KN injection clamping force and fully electric servo-driven precision (Inovance/Weichi systems), this machine is the definitive solution for producing premium cosmetic containers, pharmaceutical vials, and high-durability baby bottles.

Expert Insight: Unlike standard 3-station units, the 4-station architecture of the HGY150-V4 includes a dedicated temperature conditioning zone. This is the “secret weapon” for molding complex shapes (non-round bottles) and materials like PCTG or Tritan with zero defects. Furthermore, it is engineered to be fully compatible with Japanese ASB-12M molds, offering a seamless, cost-effective upgrade path for your existing production lines.

HGY150-V4 Overview: The 4-Station Advantage

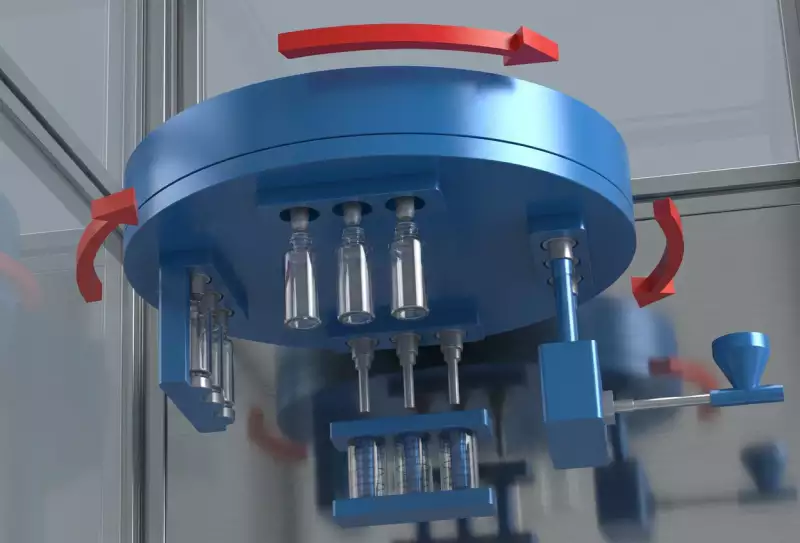

In the world of One Step PET Bottle Machine technology, the station count dictates the capability. The HGY150-V4 integrates the four critical stages—Injection, Conditioning, Stretch Blowing, and Ejection—into a synchronized, continuous thermal loop. This “One Step” methodology utilizes the residual heat from the injection phase, eliminating the need to reheat preforms from room temperature.

The result? An ISBM Machine that delivers crystal-clear bottles without the surface scuffing common in two-step processes, while reducing energy consumption by approximately 40%. It is the ideal choice for brands looking to produce high-value packaging in PET, PETG, PC, and PP.

Key Engineering Highlights

- Servo-Driven Precision: Powered by 3 sets of servo pump systems and 43.2KW servo motors, ensuring repeatability within 0.01mm for neck finishes.

- Global Component Ecosystem: We utilize Parker (USA) high-pressure valves, YUKEN (Taiwan) hydraulic controls, and AirTAC cylinders for maximum reliability.

- Versatile Mold Compatibility: Specifically designed to accept ASB-12M style molds, protecting your legacy tooling investment.

Technical Specifications: HGY150-V4

The following data represents the rigorous engineering standards of our One Step Injection Molding Machine. These parameters are crucial for verifying compatibility with your production requirements.

1. Machine Technical Standards

| Component / System | Specification & Brand |

|---|---|

| Servo System | 3 Sets of Servo Pump Systems |

| Servo Motor Power | 43.2 KW (Inovance / Weichi) |

| PLC Controller | Inovance / MIRLE (Taiwan) |

| Turntable Motor | Yaskawa (Japan) / Weichi with Tsuntien Reducer (Taiwan) |

| High Pressure Valve | Parker (USA) |

| Hydraulic Control Valve | YUKEN (Taiwan) |

| Heating System | Nano-far-infrared energy-saving heating ring (10KW) |

| Mold Compatibility | Compatible with Japanese ASB-12M molds |

2. Machine Parameters & Capabilities

| Parameter Item | Value (HGY150-V4) |

|---|---|

| Screw Diameter | 50mm (Optional: 40/55/60mm) |

| Theoretical Injection Capacity | 310g (380g/480g with larger screws) |

| Injection Clamping Force | 150 KN |

| Blowing Clamping Force | 200 KN (Single Side) |

| Upper Mold Stroke | 250 mm |

| Lower Mold Stroke | 205 mm |

| Temp. Regulating Core/Barrel Stroke | 250 mm / 230 mm |

| Take-out Stroke | 170 mm |

| Total Power | 53.2 KW |

| Machine Dimensions (L*W*H) | 4200 x 1400 x 2900 mm |

| Machine Weight | 6 Tons |

3. Production Capacity Specifications

| Cavities | Max Bottle Dia (mm) | Max Neck Dia (mm) | Max Volume (ml) |

|---|---|---|---|

| 1 | 118 | 83 | 2500 |

| 2 | 80 | 62 | 1500 |

| 4 | 56 | 38 | 400 |

| 6 | 45 | 25 | 100 |

| 8 | 26 | 15 | 20 |

Deep Dive: The 4-Station ISBM Technology Flow

The One Step Injection Blow Molding process integrated into the HGY150-V4 is the industry gold standard for pharmaceutical and high-end cosmetic containers. Unlike standard blow molding, the “One Step” method takes raw resin pellets and transforms them into finished bottles in a continuous, enclosed loop. This ensures the material is never touched by human hands or exposed to ambient dust until the bottle is fully formed and ejected.

Process Visualization

Injection of Preform via Hot Runner

Temp Equalization & Tail Cutting

Biaxial Orientation & Shaping

Automated Robot Take-out

Why Choose Our HGY150-V4?

- High Material Utilization: The hot runner system minimizes sprue waste, making it eco-friendly and cost-effective.

- Superior Physical Properties: The stretching process orients the molecular structure, significantly improving barrier properties and drop-impact resistance.

- High Precision & Stability: Full process automation reduces human error, ensuring consistent wall thickness suitable for mass production.

Technology Face-off: One-Step vs. Two-Step

For manufacturers deciding between a One Step Blow Molding Equipment setup and a traditional Two-Step line, the differences in operational efficiency are stark.

| Comparison Dimension | Ever-power One-Step ISBM | Traditional Two-Step Method |

|---|---|---|

| Process Continuity | Continuous (Pellet to Bottle) | Discontinuous (Requires Preform Storage) |

| Energy Efficiency | High (Uses Residual Injection Heat) | Lower (Requires Re-heating Preforms) |

| Surface Quality | Flawless (No Scuffs/Scratches) | Risk of Scuffing during Transport |

| Space Requirement | Compact (4.2m length) | Large (Injection Machine + Blow Molder) |

| Hygiene Level | Medical/Food Grade (Closed Loop) | Vulnerable to Contamination |

Industry Applications

The ISBM Blow Molding Machine is the engine behind many of the world’s most recognizable premium packages. Explore more specialized solutions in our 4-Station ISBM Machine category.

Premium Cosmetics

Production of heavy-wall cream jars and mascara bottles using PETG/PCTG. The 4-station process ensures even distribution of material for a glass-like feel.

Pharmaceuticals

The HGY150-V4 is ideal for eye drop bottles and pill containers (5ml to 200ml) where neck precision and sterility are non-negotiable.

Baby Care (PPSU/Tritan)

Capable of processing high-temperature resins like PPSU and Tritan for baby feeding bottles that must withstand repeated sterilization.

Global Standards & Compatibility

Ever-power has engineered the HGY150-V4 to be a direct, high-performance alternative to the market leaders. Our critical advantage lies in ASB-12M Compatibility.

The Ever-power Promise: Manufacturers currently using Japanese machines (like the ASB-12M) can migrate to the HGY150-V4 without discarding their existing molds. We offer the same cycle times and precision at a significantly more accessible investment point, backed by global components from Parker, Yaskawa, and YUKEN. *Disclaimer: ASB and Aoki are trademarks of their respective owners. Ever-power is an independent manufacturer of compatible machinery.*

[Southeast Asia] Extreme Humidity Production Research

Operating in regions like Vietnam, Thailand, or Southern China presents unique challenges due to humidity. PET is hygroscopic, and excess moisture causes hydrolysis, leading to brittle bottles. The HGY150-V4 addresses this with a sealed conditioning circuit and compatibility with advanced dehumidifying dryers. In a recent deployment for a Thai cosmetic client, we maintained a dew point of -40°C in the feed throat, ensuring PCTG bottles remained haze-free even during the monsoon season.

Investment Analysis: Profitability of ISBM

For a medium-sized beverage or cosmetic plant, the HGY150-V4 offers a compelling ROI scenario:

- Reduced Energy Load: Eliminating the preform reheating oven cuts electricity usage by ~40% per bottle compared to a 2-step line.

- Labor Optimization: The “One Step” process removes the need for preform loading staff and inventory management, effectively halving the labor requirement.

- Scrap Reduction: Automated defect rejection and stable servo control reduce scrap rates to below 0.5%.

Estimated Payback Period: For a plant running 24/7 producing 50ml cosmetic bottles, the energy and labor savings typically recoup the machine investment within 14-18 months.

Engineers’ FAQ: Common Questions

Can this machine run molds from ASB?

Yes, the HGY150-V4 is specifically designed to be compatible with Japanese ASB-12M molds, allowing for seamless integration into existing lines.

What is the maximum cavity number?

It supports up to 8 cavities for small pharmaceutical bottles (approx 20ml), or a single cavity for large containers up to 2.5L.

Is the machine fully hydraulic or electric?

It is a hybrid servo system. Rotation and critical movements are servo-driven for precision, while robust hydraulics (controlled by YUKEN valves) handle the high-force clamping requirements.

What materials are supported?

PET, PETG, PC, PP, PS, and Tritan are all supported. We can adjust the screw geometry based on your primary material to prevent shear heat degradation.

Global Case Studies: Field Notes

1. USA (New Jersey) – Pharma: A pharmaceutical company replaced two legacy hydraulic machines with one HGY150-V4 to produce sterile eye drop bottles. Result: 30% energy saving and ISO Class 7 cleanroom compliance.

2. China (Guangzhou) – Personal Care: A major supplier for Blue Moon detergent used this ISBM Bottle Machine for their high-end travel size bottles. Result: Achieved a 99.8% acceptance rate on optical clarity.

3. Italy (Milan) – Cosmetics: A boutique cosmetic packer needed to run heavy-wall PETG jars. The 4-station process allowed enough cooling time to prevent deformation. Result: Premium packaging that rivals glass.

4. Mexico (Monterrey) – Food: A food jar manufacturer utilized the 6-cavity setup for wide-mouth peanut butter jars, maximizing output in a limited factory footprint.

5. Turkey (Istanbul) – Household: Produced high-transparency PC water bottles. The machine’s precise injection control eliminated the black specks common in recycled PC processing.

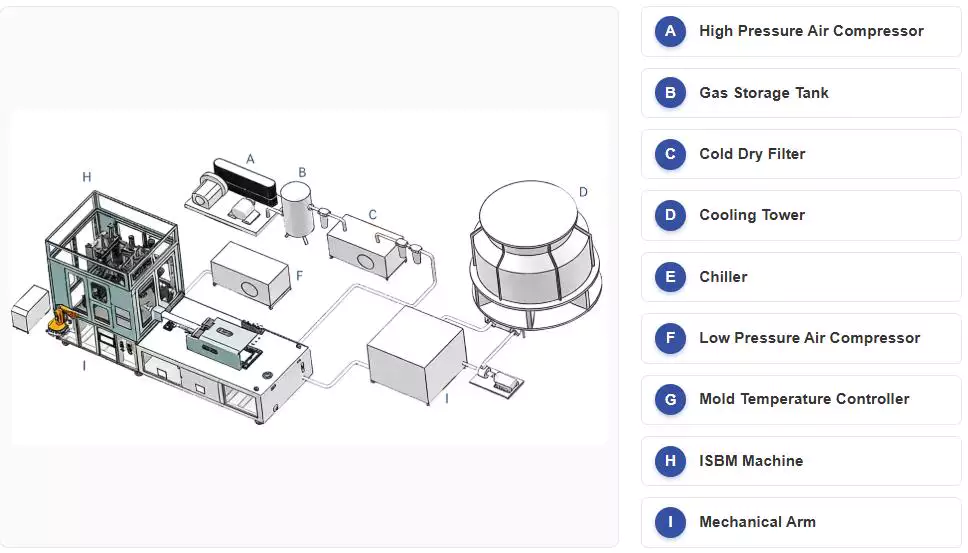

Complete Your Production Line

A pristine blowing process requires contaminant-free air, especially for pharma and cosmetic applications. Enhance your production quality with our industrial-grade Oil-Free Air Compressors, specifically designed to pair with our ISBM units.

Ready to Upgrade Your Packaging Efficiency?

Contact Ever-power’s engineering team today for a free cycle time calculation, mold design consultation, and ASB compatibility check.