Description

One Step Blow Molding Machine HGY200-V4-B: The AOKI-250 Compatible Heavy-Duty ISBM Solution

Engineered by Ever-power | 4-Station Precision | 300KN Injection Clamping | 250KN Blow Clamping

Engineering Overview: Breaking the Mold Compatibility Barrier

In my two decades of optimizing polymer processing lines, the most common bottleneck I’ve encountered isn’t cycle time—it’s tooling flexibility. Many manufacturers are locked into expensive ecosystems. The HGY200-V4-B is Ever-power’s strategic answer to this challenge. This is a heavy-duty, 4-station One Step Blow Molding Machine specifically engineered to be fully compatible with Japanese AOKI-250 molds.

This machine is a powerhouse. Unlike standard 4-station units, the V4-B variant is reinforced to handle massive cavitation (up to 12 cavities for small vials) and heavy-weight containers. It boasts a 300KN Injection Clamping Force and an upgraded 250KN Blow Clamping Force (higher than the standard V4’s 200KN). This additional clamping power allows for the production of wide-mouth jars and thick-walled cosmetic containers without parting line expansion or flash, even when using materials with high viscosity like PC or PCTG. It is the ultimate One Step PET Bottle Machine for manufacturers seeking to expand capacity using their existing high-value Japanese tooling.

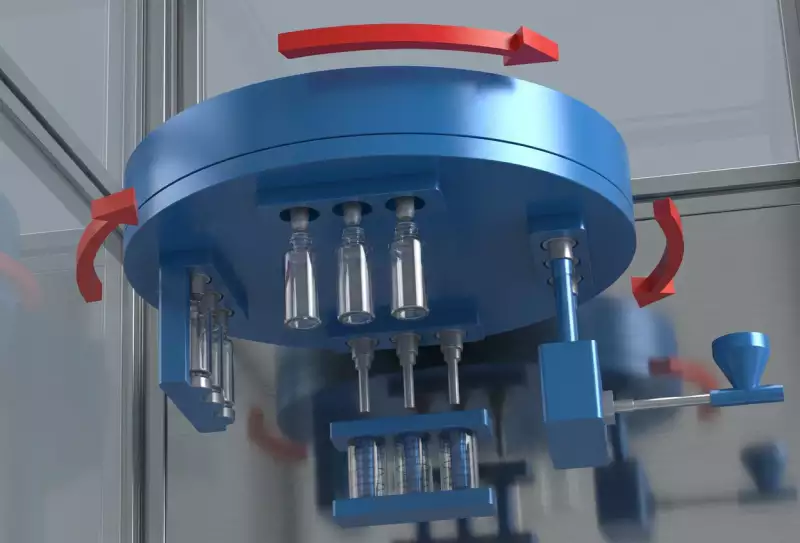

Figure 1: The Ever-power HGY200-V4-B (AOKI-250 Compatible Model)

1. Technical Standard Configuration

We do not compromise on kinetics or thermal control. The HGY200-V4-B integrates a “Who’s Who” of global engineering components to ensure it matches the reliability of the Japanese machines it is designed to complement.

| System / Component | Brand / Specification |

|---|---|

| Servo System | 3 sets of servo pump systems |

| Servo Motor Power | 49.2KW (Inovance / WEICHI) |

| Control System (PLC) | Inovance / MIRLE (High-speed logic processing) |

| Turntable Rotation | Yaskawa Servo (Japan) or WEICHI Servo + TSUNTIEN Reducer (Taiwan) |

| Blow Molding Structure | Hydraulic cylinder or Dual servo motor mold damping system with high-pressure compensation |

| High Pressure Valve | Parker (USA) |

| Pneumatic Cylinder | Airtak (Germany/Taiwan Technology) |

| Temperature Control | Integrated Control Box (High accuracy for consistent viscosity) |

| Hydraulic Control | YUKEN (Taiwan) Pressure Control Valve |

| Screw Heating | Nano-far-infrared energy-saving heating ring (15KW) |

| Injection Unit Control | Single cylinder control (Hydraulic or Servo Melt Motor options) |

| Mold Compatibility | Compatible with Japanese AOKI-250 mould |

| Total Power | 64.2 KW |

2. Machine Parameters: The Heavy-Duty Specification

The “B” in V4-B signifies enhanced capability. Note the increased shot weight (442g) and Blow Clamping Force (250KN) compared to standard models, designed for the rigors of AOKI tooling requirements.

| Parameter | Value |

|---|---|

| Screw Diameter | 50mm (Standard) / Options: 40, 55, 60mm |

| Theoretical Injection Capacity | 442g (High volume capacity) |

| Injection Clamping Force | 300 KN |

| Blowing Clamping Force | 250 KN (Upgraded for heavy molds) |

| Upper Mold Stroke | 600 mm |

| Lower Mold Stroke | 350 mm |

| Temp. Regulating Core Stroke | 300 mm |

| Temp. Regulating Barrel Stroke | 350 mm |

| Take-out Stroke | 175 mm |

| Blow Core Stroke | 300 mm |

| Blow Mold Stroke | 75 + 75 mm |

| Oil Tank Volume | 300 L |

| Machine Dimensions (L*W*H) | 4800 x 2000 x 3800 mm |

| Machine Weight | 13 Tons |

Production Capacity: Versatility from Jars to Vials

| Product Quantity (Cavities) | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|

| Max Bottle Diameter (mm) | 118 | 110 | 105 | 100 | 68 | 65 | 48 | 45 | 38 | 26 |

| Max Bottle Height (mm) | 280 (Increased Height) | 150 | 100 | |||||||

| Neck Diameter (mm) | 90 | 90 | 90 | 65 | 38 | 32 | 26 | 25 | 23 | 15 |

| Max Bottle Volume (ml) | 2500 | 1500 | 900 | 750 | 350 | 200 | 100 | 50 | 30 | 20 |

| Max Bottle Weight (g) | 150 | 65 | 45 | 35 | 30 | 28 | 25 | 20 | 15 | 10 |

4-Station Process Principle: The ISBM Advantage

The ISBM Blow Molding Machine maximizes quality by controlling the polymer’s thermal history. The HGY200-V4-B employs a 4-station rotary table layout, ensuring that the preform is conditioned to the exact optimal temperature before stretching.

1. Injection Station

PET/PCTG is injected into the cavity. The 300KN clamping force is critical here, allowing for high-pressure injection needed for precision necks and thin-wall preforms without flash.

2. Conditioning Station

The “Heart” of the 4-station process. The preform is thermally equalized. We can heat the core or cool the skin, creating the perfect profile for difficult shapes like oval bottles or off-center necks.

3. Stretch & Blow

A stretch rod extends the preform axially, while air expands it radially. The upgraded 250KN Blow Clamping Force ensures the mold stays shut under high pressure, eliminating parting lines.

4. Ejection

The finished container is stripped from the lip mold. The HGY200-V4-B features an extended take-out stroke (175mm) to accommodate taller bottles (up to 280mm).

Why Choose the HGY200-V4-B? Core Advantages

- ✓

AOKI-250 Mold Compatibility: This is the defining feature. We have engineered the platen dimensions, tie-bar spacing, and stroke lengths to perfectly match the AOKI-250. You can run your legacy molds immediately. - ✓

Superior Clamping Power: With 300KN Injection and 250KN Blow clamping, this machine outperforms standard market alternatives, ensuring flash-free production of heavy-weight jars. - ✓

Energy Dynamics: We use Nano-far-infrared heating rings (15KW) which penetrate the barrel deeper and faster than standard ceramic heaters, saving ~30% on heating costs. - ✓

Versatility: From 12-cavity eye drop vials to 4-cavity 750ml sport bottles, the machine adapts. The increased bottle height allowance (280mm) opens up new market segments.

Strategic Analysis: One-Step vs. Two-Step Systems

| Comparison Dimension | Ever-power One-Step ISBM | Traditional Two-Step (Reheat) |

|---|---|---|

| Process Flow | Resin -> Bottle (Integrated) | Resin -> Preform -> Cool -> Reheat -> Bottle |

| Energy Efficiency | High (Uses latent injection heat) | Low (Wastes energy reheating preforms) |

| Surface Quality | Flawless (No scuffing/scratches) | Risk of transport scratches on preforms |

| Applicable Materials | PET, PETG, PC, Tritan, PPSU, PP | Mostly limited to PET/PP |

| Space Requirement | Compact (One machine) | Large (Requires Injection unit + Blow unit + Storage) |

| Scrap Rate | Low (Closed loop feedback) | Higher (Preform defects + Blow defects) |

Industry Applications

High-End Cosmetics

The One Step Injection Blow Molding process is the only way to achieve glass-like clarity for thick-walled cosmetic jars. The HGY200-V4-B’s 250KN blow clamp eliminates the “parting line visibility” issue common in lower-end machines.

Pharmaceuticals

From 20ml eye drop vials (12 cavities) to 500ml syrup bottles. The touchless “pellet-to-bottle” process guarantees ISO-standard hygiene levels.

Tritan™ & Sports Bottles

Tritan and PC require precise temperature control to avoid hazing. Our 4-station conditioning allows for exact thermal profiling to maintain the clarity of these expensive resins.

Power System Selection Summary: Ever-power vs. AOKI/ASB

We respect the Japanese pioneers. However, Ever-power offers a compelling alternative: 95% of the performance at 60% of the investment cost.

The Ever-power Guarantee: The HGY200-V4-B isn’t a “cheap copy.” It uses the same Yaskawa servos, Parker valves, and NSK screws. We simply optimize the manufacturing overhead.

ROI Case: Cosmetic Jar Manufacturer

Switching from purchasing preforms to an in-house One Step Blow Molding Equipment setup:

- Tooling Savings: If you already own AOKI-250 molds, you save $30,000-$50,000 immediately by not needing new molds.

- Material Savings: Pellet cost is ~25% lower than preform cost.

- Payback Period: With existing molds, the ROI is often achieved in under 10 months.

[Global] Extreme Condition Resilience

For our clients in varying climates, the HGY200-V4-B is equipped with an advanced hydraulic oil cooling loop. Whether you are operating in the humid summers of Southeast Asia or the freezing winters of Russia, the system maintains a stable oil temperature of 40-50°C, ensuring consistent clamp pressure and cycle times.

Compliance: CE Certified, UL Electrical Standards compliant upon request.

Engineer’s FAQ

Can I really use my AOKI-250 molds without modification?

Yes. The platen layout, tie-bar spacing, and daylight opening are engineered to match. In some rare cases with very old molds, minor adaptor plates might be needed, but 99% of AOKI-250 molds fit directly.

What is the max shot weight?

The machine boasts a theoretical injection capacity of 442g, which is significantly higher than many standard competitors, allowing for very thick-walled luxury containers.

Do you provide installation?

Yes, we send engineers globally for installation, commissioning, and training of your staff.

Global Case Studies: Engineer Field Notes

Thailand: Retrofit Success

“We had 5 AOKI machines and needed to expand. The HGY200-V4-B ran our existing molds perfectly.” – Plant Manager, Bangkok

Brazil: Heavy Jars

“The 250KN blow clamp solved our flashing issue on the 200g cream jars.” – Tech Director, São Paulo

Germany: Energy Saving

“The servo system reduced our electricity bill by 35% compared to our older hydraulic units.” – Ops Lead, Hamburg

Vietnam: High Volume

“Running 12 cavities for eye drops, stable cycle times 24/7.” – Production Head, Hanoi

Swipe to view more client success stories

Complete Your Production Line

Ensure contamination-free air for your blowing process with our specialized Oil-Free Air Compressor.

Leverage Your Existing Tooling Today

Don’t let high machine costs stall your expansion. Experience the precision and compatibility of the HGY200-V4-B.