Description

One Step Injection Stretch Blow Molding Machine HGY250-V4-B: High-Output Double-Row 4-Station ISBM Technology

Engineered by Ever-power | Double-Bank Cavitation (Up to 28 Cavities) | 680g Shot Capacity

Engineering Overview: The “Double-Row” Productivity Multiplier

In the high-volume production of small-format containers—such as pharmaceutical vials, hotel amenities, and mini-liquor bottles—cycle time is only half the battle. The real victory lies in cavitation density. As an engineer who has spent two decades optimizing One Step Blow Molding Machine layouts, I present the HGY250-V4-B. This is not just a standard machine; it is a “Double-Row” (Double Bank) powerhouse designed to effectively double your output per footprint.

The HGY250-V4-B operates on a 4-station rotary indexing system but utilizes a specialized mold layout that accommodates two rows of cavities. This allows for an astounding 16 to 28 cavities for bottles under 100ml, while maintaining a robust 300KN Injection Clamping Force. By injecting a massive theoretical shot weight of 680g, this machine is specifically engineered for manufacturers who need to produce millions of units of high-quality, flash-free PET or PETG containers annually without investing in multiple standard machines. It is the ultimate high-efficiency solution in the ISBM Machine sector.

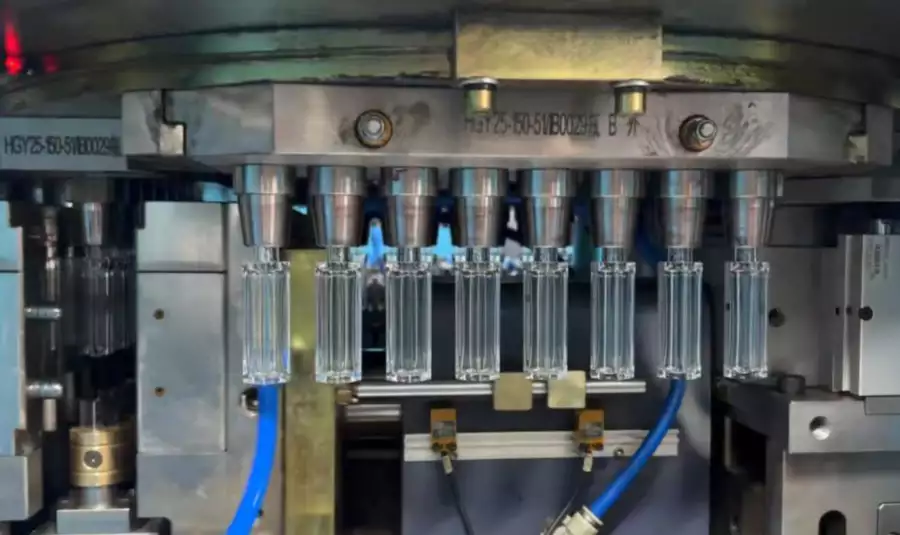

Figure 1: The Ever-power HGY250-V4-B Double-Row High Output Unit

1. Technical Standard Configuration

To handle the stress of double-row molding, the HGY250-V4-B is reinforced with heavy-duty hydraulics and high-torque servos. We utilize top-tier global components to ensure 24/7 reliability under high-load conditions.

| System / Component | Brand / Specification |

|---|---|

| Servo System | 3 sets of servo pump systems |

| Servo Motor Power | 67.7KW (Inovance / WEICHI) |

| Control System (PLC) | Inovance / MIRLE (Dual-core processing for multi-cavity logic) |

| Turntable Rotation | Yaskawa Servo (Japan) or WEICHI Servo + TSUNTIEN Reducer |

| Blow Molding Structure | Hydraulic cylinder or Dual servo motor mold clamping with high-pressure compensation |

| High Pressure Valve | Parker (USA) |

| Pneumatic Cylinder | Airtak (Germany/Taiwan Technology) |

| Temperature Control | Integrated Control Box (Multi-zone control for double row preforms) |

| Hydraulic Control | YUKEN (Taiwan) Pressure Control Valve |

| Screw Heating | Nano-far-infrared energy-saving heating ring (15KW) |

| Injection Unit Control | Single cylinder control (Hydraulic or Servo Melt Motor) |

| Oil Tube | Imported material from Italy |

| Total Power | 82.7 KW |

2. Machine Parameters: High Capacity Specs

The HGY250-V4-B is defined by its massive shot capacity and specialized stroke lengths to accommodate the double-row mold configuration.

| Parameter | Value |

|---|---|

| Screw Diameter | 60mm (Standard) / Options: 50, 55mm |

| Theoretical Injection Capacity | 680g (Range: 315 – 480 cm³) |

| Injection Clamping Force | 300 KN |

| Blowing Clamping Force | 250 KN (Single Side) |

| Upper Mold Stroke | 600 mm |

| Lower Mold Stroke | 200 mm |

| Temp. Regulating Core Stroke | 250 mm |

| Temp. Regulating Barrel Stroke | 250 mm |

| Take-out Stroke | 200 mm |

| Blow Core Stroke | 300 mm |

| Blow Mold Stroke | 75 + 75 mm |

| Oil Tank Volume | 300 L |

| Machine Dimensions (L*W*H) | 5200 x 2500 x 3800 mm |

| Machine Weight | 16 Tons |

Production Capacity: Double-Row Cavity Matrix

This table demonstrates the “Double-Row” advantage. Note the high cavitation counts (14, 16, 20, 24, 28) available for smaller diameters.

| Product Quantity (Cavities) | 8 | 10 | 12 | 14 | 16 | 20 | 24 | 28 |

|---|---|---|---|---|---|---|---|---|

| Max Bottle Diameter (mm) | 85 | 85 | 79 | 66 | 54 | 45 | 37 | 25 |

| Max Bottle Height (mm) | 260 | |||||||

| Neck Diameter (mm) | 58 | 56 | 48 | 38 | 32 | 26 | 24 | 15 |

| Max Bottle Volume (ml) | 1000 | 900 | 800 | 600 | 400 | 250 | 100 | 50 |

| Max Bottle Weight (g) | 55 | 44 | 36 | 32 | 28 | 25 | 20 | 15 |

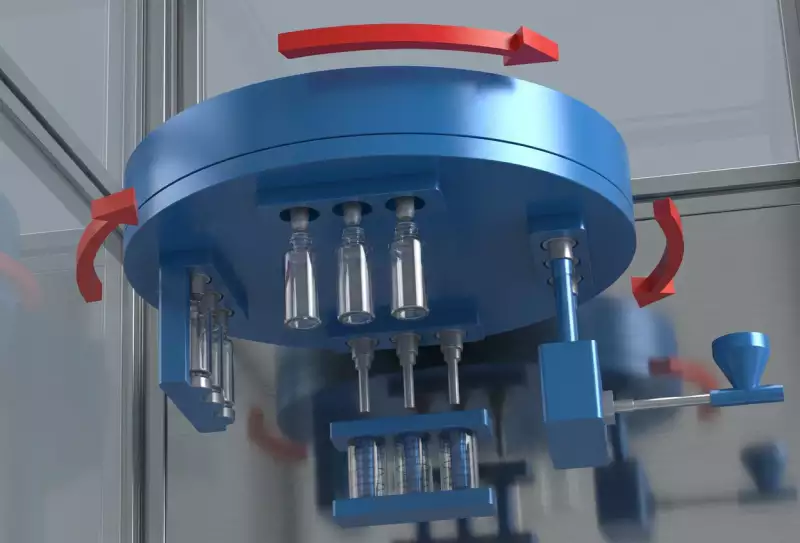

Core Technology: 4-Station Double-Row ISBM Process

The One Step PET Bottle Machine maximizes quality by controlling the polymer’s thermal history. The HGY250-V4-B employs a unique 4-station process that handles two rows of bottles simultaneously, doubling throughput without sacrificing precision.

1. Double-Row Injection

Molten PET is injected into a double-row cavity plate. The 300KN clamping force and 680g shot capacity ensure equal pressure across all 28 cavities (in max configuration), preventing short shots.

2. Uniform Conditioning

The double row of preforms is transferred to the conditioning station. Advanced thermal regulation ensures that inner and outer rows receive identical heat profiles for consistent stretching.

3. Precision Stretch & Blow

Stretch rods extend the preforms axially while 2.0-3.5 Mpa air expands them. The 250KN Blow Clamping Force ensures zero parting lines, even when molding 28 bottles at once.

4. Mass Ejection

Finished bottles are stripped from the lip molds. The touchless process makes this machine ideal for high-volume pharmaceutical and food-grade applications.

Why Choose the HGY250-V4-B? Core Advantages

- ✓

Extreme Cavitation (Double Bank): While most machines stop at 12 or 16 cavities, the V4-B pushes to 28 cavities for small diameter products (25mm), fundamentally changing the economics of vial production. - ✓

High Shot Weight (680g): This allows for heavy-wall, high-quality manufacturing even in high-cavity setups. You don’t have to sacrifice bottle weight/quality for quantity. - ✓

Energy Dynamics: Despite the high output, the servo-driven system ensures that energy is only consumed during movement, reducing the cost-per-bottle significantly compared to running two smaller machines. - ✓

Space Efficiency: You get double the production output of a standard machine in a footprint of just 5.2m x 2.5m.

Strategic Analysis: One-Step vs. Two-Step Systems

| Comparison Dimension | Ever-power One-Step ISBM | Traditional Two-Step (Reheat) |

|---|---|---|

| Process Flow | Resin -> Bottle (Integrated) | Resin -> Preform -> Cool -> Reheat -> Bottle |

| Energy Efficiency | High (Uses latent injection heat) | Low (Wastes energy reheating preforms) |

| Surface Quality | Flawless (No scuffing/scratches) | Risk of transport scratches on preforms |

| Applicable Materials | PET, PETG, PC, Tritan, PPSU, PP | Mostly limited to PET/PP |

| Small Bottle Efficiency | Excellent (Double row handles small preforms well) | Poor (Reheating small preforms is unstable) |

| Hygiene Level | Medical/Food Grade (Touchless) | Standard (Exposed to open air storage) |

Industry Applications

Pharmaceuticals (Vials & Droppers)

The One Step Injection Blow Molding machine is the industry standard for 5ml-20ml eye drop and vaccine bottles. The HGY250-V4-B’s 28-cavity capability maximizes output for these small, high-precision items.

Hotel Amenities

Perfect for 30ml-50ml shampoo and lotion bottles. The double-row setup allows for massive daily production volumes required by global hotel chains.

Mini-Liquor / Spirits

Ideal for 50ml PET spirit bottles (airline bottles). The heavy injection weight allows for thick walls that mimic glass, while the high cavitation keeps unit costs low.

Power System Selection Summary: Ever-power vs. Competitors

Compared to single-row machines from competitors, the HGY250-V4-B offers a significant leap in productivity.

The Ever-power Guarantee: We use the same high-end servo systems (Yaskawa/Inovance) as premium brands, but our double-bank design allows you to produce 50-80% more product in the same amount of floor space.

ROI Case: Eye Drop Vial Manufacturer

Switching from a standard 8-cavity machine to the HGY250-V4-B (24-cavity setup for 15ml vials):

- Output Increase: 300% increase in bottles per cycle.

- Energy Savings: You are running one machine instead of three to get the same output.

- Payback Period: Typically 8-12 months due to the massive volume capability.

[Global] Extreme Condition Resilience

For our clients in varying climates, the HGY250-V4-B is equipped with a high-capacity machine oil cooler (0.3-0.4 Mpa water pressure required). Whether you are operating in the heat of India or the cold of Russia, the system maintains a stable oil temperature of 20-25°C, ensuring consistent clamp pressure and cycle times.

Compliance: CE Certified, UL Electrical Standards compliant upon request.

Engineer’s FAQ

What is the benefit of a “Double Row” or “Double Bank” machine?

It allows you to fit more cavities into the mold by staggering them or placing them in two parallel lines. This is the only way to achieve high cavitation (20+) for small bottles on a machine of this size.

Can I run large bottles on this machine too?

Yes, you can run larger bottles (up to 1L) by using a mold with fewer cavities (e.g., 8 cavities). However, the machine is optimized for high-volume small containers.

Does the double row setup affect temperature conditioning?

No, our conditioning station is specifically designed with multi-zone heating/cooling to ensure that the inner row and outer row of preforms receive the exact same thermal treatment.

Global Case Studies: Engineer Field Notes

South Korea: 10ml Vials

“Running 24 cavities of eye drop bottles. The precision is incredible for such high output.” – Plant Manager, Seoul

Turkey: Hotel Amenities

“We supply hotel chains. The HGY250-V4-B allowed us to double production without buying two machines.” – Director, Istanbul

Mexico: Mini-Tequila

“50ml heavy-wall PET bottles. The machine handles the 16-cavity mold with ease.” – Ops Lead, Jalisco

India: Syrup Bottles

“The cooling system handles our hot summers perfectly. Output is stable.” – Tech Lead, Gujarat

Indonesia: Cosmetics

“High cavitation for mascara tubes. No other machine offered this output at this price.” – Production Head, Jakarta

Swipe to view more client success stories

Complete Your Production Line

Ensure contamination-free air for your blowing process with our specialized Oil-Free Air Compressor.

Maximize Your Output Density

Don’t limit your production to single rows. Experience the efficiency of the HGY250-V4-B Double Bank machine.