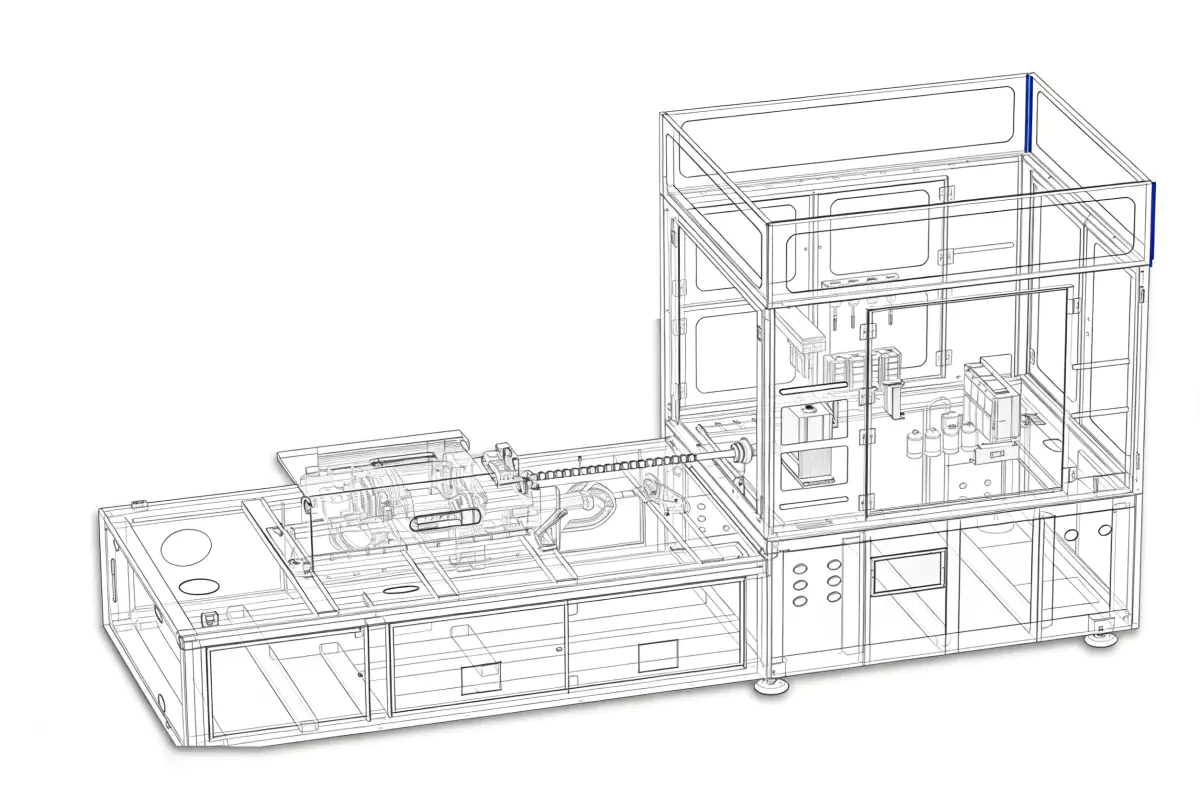

The HGY Series: Engineering Excellence for Cosmetic Packaging

Engineering the “Glass-Like” Aesthetic: Challenges & Opportunities

In my 20 years of field experience designing production lines for the cosmetics sector, I have witnessed a definitive shift. Brands no longer just want plastic; they want the visual weight and clarity of glass combined with the safety and cost-efficiency of PET or PETG. This is particularly true for Heavy-Wall Jars and Bottles used in premium creams, serums, and lotions.

The challenge with traditional manufacturing? It’s thermal management. Achieving a wall thickness of 3mm to 5mm without haziness, crystallization, or flow marks is a nightmare for standard two-step processes. The preforms cool unevenly, and reheating them to the core without melting the surface is nearly impossible.

This is where the One Step Blow Molding Machine (ISBM) technology becomes not just an option, but a necessity. By integrating injection, conditioning, and blowing into a single thermal cycle, we maintain the “heat history” of the material, ensuring absolute transparency and structural integrity.

Core Technical Speed Read

- Core Technology: 4-Station One-Step Injection Stretch Blow Molding (ISBM).

- Critical Capability: Active Conditioning Station (Temperature Profiling) essential for heavy-wall thickness (3mm-5mm).

- Material Focus: Optimized for PET, PETG, PCTG, and Tritan without crystallization.

- Cycle Efficiency: Zero energy waste on reheating; 40% energy reduction compared to Two-Step systems.

- Precision: Servo-driven turntables (Yaskawa/Inovance) ensure concentricity deviation < 0.05mm.

Why the Heavy-Wall Cosmetic Industry Demands One-Step ISBM

When you are molding a standard water bottle, the walls are thin, and cooling is rapid. However, luxury cosmetic packaging—specifically heavy-wall jars (30ml-200ml)—operates under a different set of physics. The latent heat inside a 5mm thick preform is immense.

If you use a 3-station machine or a 2-step process, the internal heat causes the PETG to crystallize (turn white) or the material to slump, leading to eccentricity. Our One Step PET Bottle Machine utilizes a dedicated Conditioning Station. Here, we don’t just “wait”; we actively manage the core temperature using conditioning rods or pots. This allows us to strip heat from the surface while keeping the core pliable for stretching. This level of control is the only way to achieve the “crystal clear” look required by brands like Estée Lauder or L’Oréal.

Core Industry Needs vs. Ever-Power Technology Matching

| Industry Pain Point | Ever-Power ISBM Solution | Technical Implementation |

|---|---|---|

| Haze & Whitening Thick walls trap heat, causing crystallization in PET/PETG. |

Active Thermal Conditioning | 4-Station design (HGY-V4) with core cooling rods to balance ΔT between inner/outer walls. |

| Parting Lines & Gates Visible seams ruin the premium “glass” illusion. |

Seamless Aesthetics | Hot runner direct injection with valve gates; split-mold precision <0.02mm gap. |

| Eccentricity Uneven wall thickness makes jars feel “cheap”. |

One-Step Concentricity | Preform is indexed on the same mandrel from injection to blow; never released or re-grabbed. |

| Scratching Surface damage during transport. |

Touchless Ejection | Automated take-out robots deposit bottles directly onto soft conveyors or packing trays. |

Typical Applications in Personal Care

Our ISBM Machine series is not limited to a single shape. The versatility of the HGY-V4 series allows for rapid mold changes to accommodate:

- Heavy-Wall Cream Jars: 30ml to 100ml jars with double-wall effects, often replacing glass for lower shipping weight.

- Luxury Lotion Bottles: High-clarity PCTG bottles with heavy bases (false bottom effect) that exude luxury.

- Serum Droppers: Small, high-precision neck finishes compatible with complex dropper assemblies.

- Airless Pump Bottles: Precise inner diameters required for the piston movement in airless systems.

- Mascara & Lip Gloss Tubes: Long L/D ratios requiring perfect straightness and neck calibration.

Ever-Power Solution Highlights: The HGY-V4 Advantage

For the heavy-wall cosmetics application, I strongly recommend the HGY150-V4 or HGY200-V4. While we offer 3-station machines for standard bottles, the 4-station configuration is non-negotiable for premium thick-walled containers.

Why the V4? It adds the “Conditioning” station between Injection and Stretch-Blow. This station allows us to:

- Adjust Temperature: Selectively heat or cool specific zones of the preform (e.g., cooling the thick body while keeping the neck rigid).

- Eliminate Stress: Relax the polymer chains before stretching to prevent optical distortion.

- Cycle Optimization: Perform cooling outside the injection mold, significantly reducing the overall cycle time compared to machines that must cool entirely in the injection phase.

Powered by Inovance/Weichi servo motors and Parker high-pressure valves, the HGY series delivers repeatability within 0.1g per shot, ensuring every jar is identical.

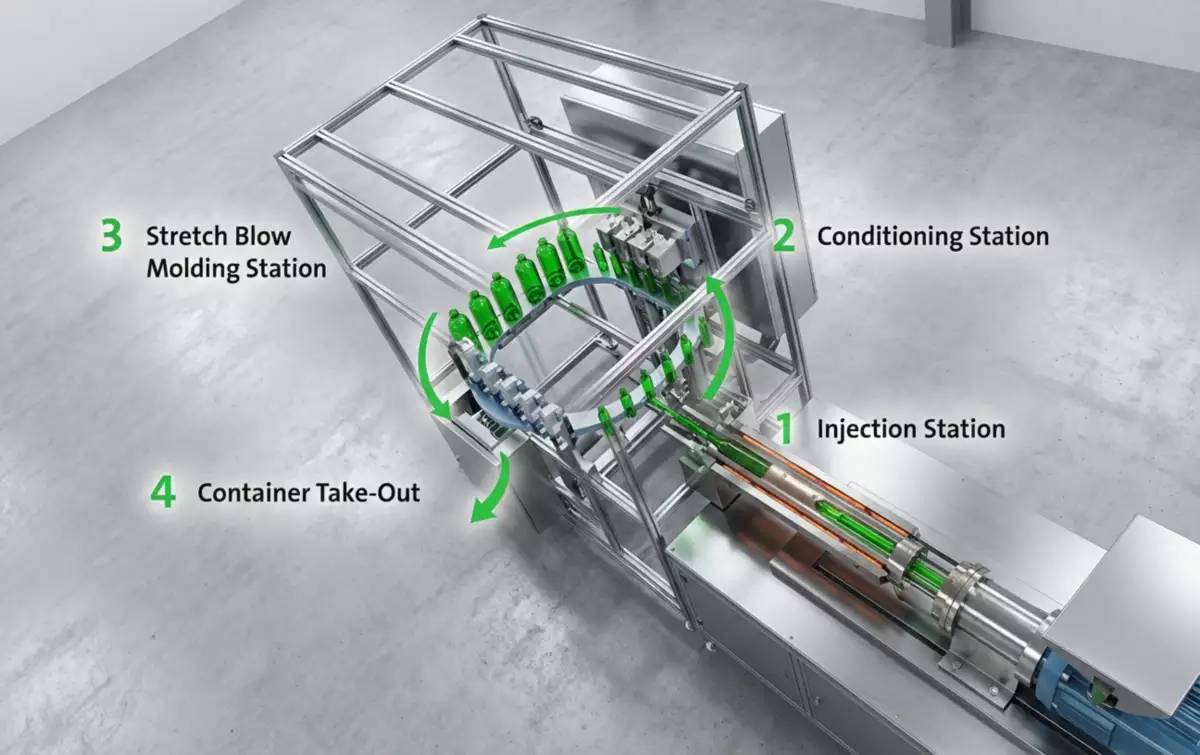

Process Flow: The 4-Station Art of ISBM

1. Injection

Molten PET/PETG is injected into a cavity to form the preform. The neck finish is molded to final dimensions with high precision.

2. Conditioning

The Critical Step. The preform is transferred to a conditioning pot. Internal/external temperature is equalized to prevent haze in thick walls.

3. Stretch Blow

The preform is stretched axially by a rod and blown radially against the mold walls to define the final shape and impart biaxial strength.

4. Ejection

The finished bottle is automatically removed. With our system, this is oriented and gentle to prevent surface scuffing.

Engineer’s Field Notes: Global Success Cases

[France] Luxury Skincare Brand – Heavy Wall Cream Jar

Challenge: The client needed a 50ml jar with a 4mm wall thickness in PETG. Their previous 2-step process resulted in 15% scrap due to “milky” haze near the gate.

Solution: Deployed HGY150-V4 with specialized “cooling pins” in the conditioning station.

Result: Transparency matched glass. Scrap rate dropped to <1%.

“Ever-Power’s conditioning technology solved the crystallization issue we fought for two years.” – Pierre D., Production Director.

[Japan] Organic Serum Manufacturer – High Concentricity Dropper

Challenge: An 18mm neck finish required absolute concentricity for an automatic dropper assembly line. Standard blow molding had too much ovality.

Solution: Used our ISBM Bottle Machine with a solid mandrel transport system.

Result: Ovality controlled within ±0.1mm. Line stoppages reduced by 90%.

[USA] Contract Packer – Multi-SKU Flexibility

Challenge: Client needed to produce 5 different bottle shapes (100ml to 300ml) on one machine with fast changeovers.

Solution: HGY200-V4 with quick-change mold bases.

Result: Mold changeover time reduced from 8 hours to 3 hours. ROI achieved in 14 months.

[Brazil] Hair Care Giant – Large Volume Production

Challenge: High energy costs were eating into margins for a 250ml shampoo bottle.

Solution: Switched from Two-step to One-step HGY series. Eliminated the reheating oven entirely.

Result: 40% reduction in electricity bills per unit produced.

[Thailand] Pharmaceutical Grade Vials

Challenge: Required ISO Class 7 cleanroom compatibility for sterile eyedrop bottles.

Solution: All-electric servo version of our ISBM machine with oil-free pneumatic exhaust.

Result: Passed all cleanroom certifications easily due to the absence of hydraulic oil leaks.

One-Step vs. Two-Step: An Engineer’s Comparison

| Feature | One-Step ISBM (Ever-Power) | Two-Step (Reheat Blow) |

|---|---|---|

| Process Flow | Continuous (Hot Preform) | Interrupted (Cold Preform Reheat) |

| Surface Quality | Pristine (No scratches) | Risk of preform tumbling marks |

| Wall Thickness Capability | Excellent (Heavy Walls possible) | Limited (Hard to reheat thick walls) |

| Energy Efficiency | High (Retains injection heat) | Low (Requires massive reheating ovens) |

| Machine Footprint | Compact (One machine) | Large (Injection + Reheat + Blower) |

[Global] Regulatory Compliance & Safety

Importing industrial machinery requires strict adherence to local regulations. Ever-Power machines are engineered to meet global standards:

- CE Marking (Europe): Fully compliant with Machinery Directive 2006/42/EC, Low Voltage Directive, and EMC Directive. Essential for our clients in France and Germany.

- UL Standards (USA/Canada): Electrical components are sourced from UL-listed suppliers (like Rockwell/Allen-Bradley options) to ensure smooth inspection in North American facilities.

- Food Contact Materials: All parts touching the polymer (screws, barrels, molds) use food-grade stainless steel compliant with FDA 21 CFR 177.1630.

- Energy Efficiency: Our servo-hydraulic systems meet Level 1 Energy Efficiency standards in China, often qualifying for Green Energy grants in customer regions.

Brand Comparison & Disclaimer

We often get asked how we compare to the Japanese giants like ASB or Aoki. We respect their technology, as they pioneered this field. However, Ever-Power offers a strategic alternative:

| Technology Level | Comparable 4-Station ISBM architecture; compatible with ASB-style molds. |

| Investment Cost | Approximately 40-50% lower capital expenditure (CAPEX) than Japanese equivalents, allowing for faster ROI. |

| Lead Time | Typically 60-90 days, compared to 6-9 months for some competitors. |

Disclaimer: Mention of third-party trademarks (ASB, Aoki) is for comparative technical purposes only. Ever-Power is an independent manufacturer.

FAQ: Expert Answers to Your ISBM Questions

Can I run recycled PET (rPET) on this machine?

Yes. Our screw geometries are optimized to handle rPET with varying Intrinsic Viscosity (IV) without degradation. We recommend a dehumidifying dryer to ensure moisture content is below 50ppm.

What is the mold life expectancy?

Our molds use high-grade S136 stainless steel with heat treatment. With proper maintenance, they easily exceed 3 million shots. We also provide mold refurbishment services.

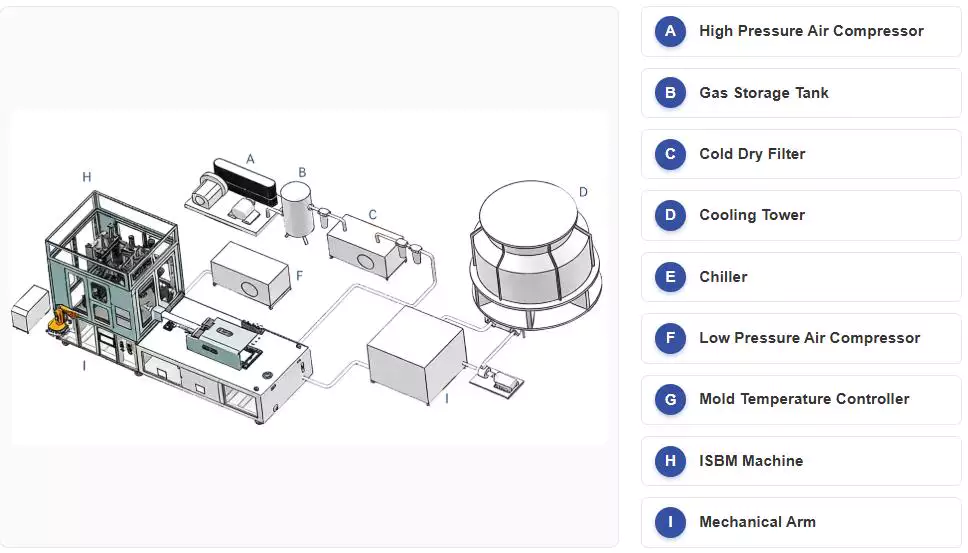

Do I need a chiller for this machine?

Yes. To achieve high cycle speeds and clarity in heavy-wall jars, a dedicated chiller is required for the injection cavity and conditioning station. We can help size this for you.

Is it difficult to change molds?

Not with the V4 series. We utilize a quick-change clamping system and provide a mold crane tool. A trained team can perform a complete changeover in 2-3 hours.

Can I produce oval bottles?

Absolutely. Our conditioning station allows for preferential heating, making it ideal for oval or non-round shapes with aspect ratios up to 2:1.

What support do you offer for installation?

We send senior engineers to your facility for installation, commissioning, and training. We don’t leave until your team is running production at the guaranteed cycle time.

What about spare parts availability?

We use standard global components (Yuken, Parker, Schneider, etc.) available locally in most countries. For proprietary parts, we ship via DHL/FedEx within 24 hours.

Why is One-Step better for hygiene?

Because the preform never touches the outside environment. It goes from molten plastic to finished sealed bottle in one sterile chamber. This is crucial for pharma and high-end cosmetics.

Related Auxiliary Equipment

To run a truly efficient One Step Injection Blow Molding line, the quality of your compressed air is paramount. Oil contamination in the blowing air can ruin an entire batch of clear cosmetic bottles.

We supply and integrate high-performance Oil-Free Air Compressors specifically designed for the blowing pressure requirements (3.0 – 3.5 MPa) of our machines. This ensures that your Heavy-Wall Jars remain chemically pure and optically flawless.

Ready to Elevate Your Cosmetic Packaging?

Don’t let crystallization and eccentricity compromise your brand’s image. Partner with the experts who understand the physics of heavy-wall molding.

Get Your Custom ISBM Solution Quote

Contact Ever-Power today for a technical consultation and ROI analysis.