1. Engineering the “Plastic Gold”: Challenges in PPSU Molding

In my 20 years of machinery engineering, few materials have disrupted a market as swiftly as Polyphenylsulfone (PPSU). Known as “Plastic Gold” for its natural amber hue and incredible durability, PPSU has replaced PC (Polycarbonate) and even glass in the premium baby bottle sector. Parents demand it because it withstands repeated steam sterilization (up to 180°C) without releasing BPA or BPS.

However, for manufacturers, PPSU is a beast. It has an extremely high processing temperature (360°C+) and high melt viscosity. Traditional two-step PET machines simply cannot handle the thermal requirements or the shear stress. Preforms often turn hazy or crack during stretching if the temperature isn’t perfectly maintained.

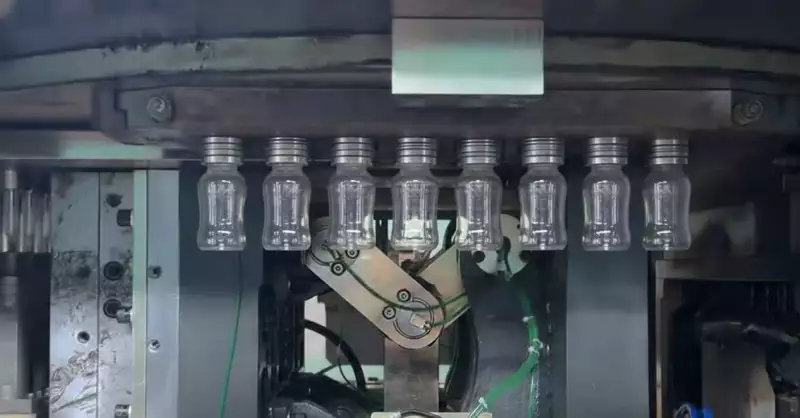

This is where the One Step Blow Molding Machine (ISBM) becomes indispensable. By using a specialized 4-station process with active thermal conditioning, we can manage the “heat history” of PPSU from injection to blow, ensuring crystal-clear, stress-free bottles that justify their premium price tag.

2. Why Premium Baby Bottles Demand One-Step ISBM

Safety and aesthetics are paramount in the maternal and infant care industry. The One-Step process offers distinct advantages for PPSU:

- Thermal Management: PPSU hardens quickly. In a two-step process, reheating a cold PPSU preform is energy-intensive and often leads to uneven stretching. One-Step ISBM utilizes the residual heat from injection, keeping the material in its optimal elastic range for blowing.

- Surface Purity: Baby bottles must be pristine. Our process eliminates preform storage and tumbling, meaning zero scratches and zero contamination risks—crucial for a product that touches milk and infant mouths.

- Neck Precision: Anti-colic vents and wide-neck teats require precise mating surfaces. ISBM injection molds the neck finish to tolerances of ±0.05mm, ensuring no leakage of precious breast milk or formula.

3. Core Industry Needs vs. Ever-power Technology Matching

| Infant Care Pain Point | Ever-power ISBM Solution | Technical Outcome |

|---|---|---|

| High Material Cost PPSU costs ~$50/kg. Scrap is expensive. |

Zero-Waste Hot Runner Valve gate technology. |

Eliminates sprue waste. Precise shot weight control saves material. |

| Optical Haze Overheating causes yellowing/clouds. |

4-Station Conditioning Precise temp profiling. |

Uniform amber transparency without burn marks or stress whitening. |

| High Process Temp Standard screws degrade. |

High-Temp Screw/Barrel Bimetallic alloy coating. |

Withstands 380°C continuous operation without wear or carbonization. |

| Complex Shapes Ergonomic “easy-grip” curves. |

Servo Stretch Rods Profiling speed control. |

Perfect distribution of material into complex curves and handles. |

4. Typical Sub-Segment Applications

Our One Step PET Bottle Machine (modified for Engineering Plastics) serves the entire infant feeding spectrum:

Standard Wide-Neck Bottles

160ml to 330ml. The industry workhorse. Requires perfect neck flatness for sealing with silicone teats.

Curved “Anti-Colic” Bottles

S-shaped or angled bottles designed to reduce air intake. Difficult to blow evenly without differential heating control.

Training Sippy Cups

Heavier wall thickness (up to 2mm) for durability when dropped by toddlers. Requires robust injection clamping force.

5. Ever-power Solution: The HGY200-V4 Advantage

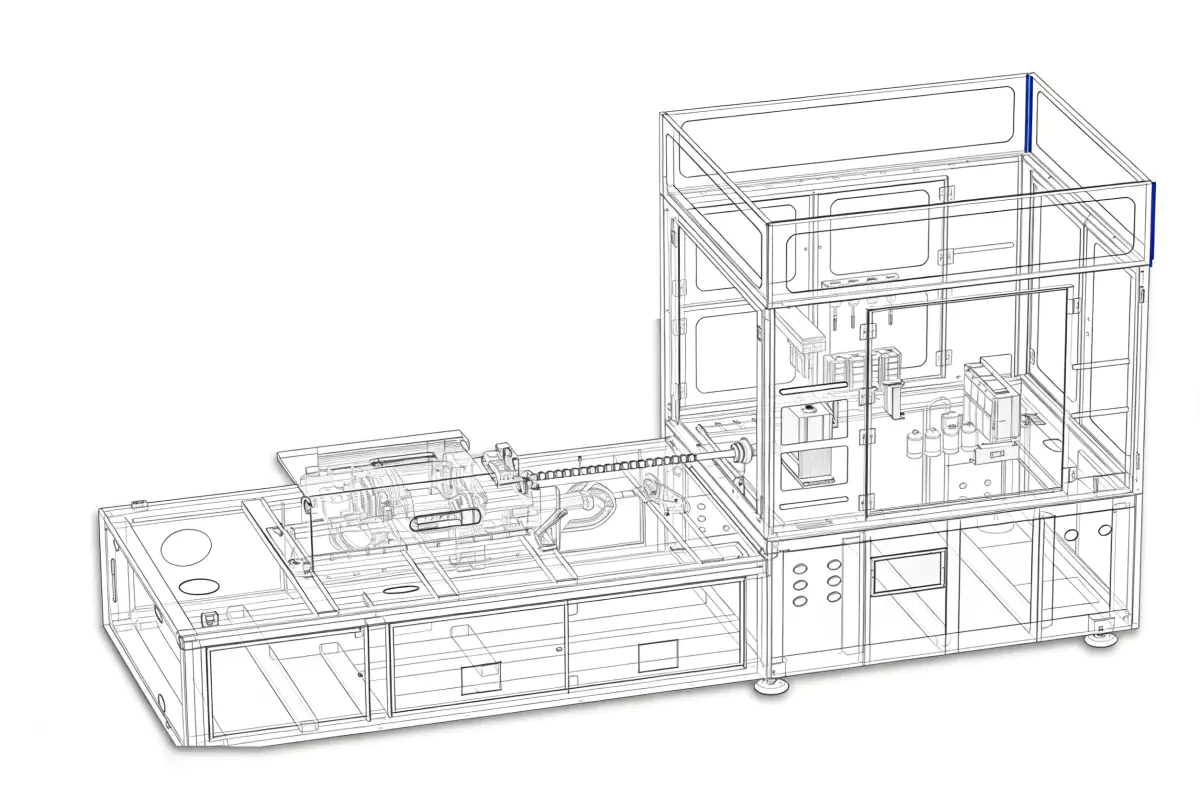

Processing PPSU requires more than a standard machine. We recommend the HGY200-V4 (4-Station), equipped with our “High-Temp Package”.

Why the V4 for PPSU?

- Station 2 (Conditioning) is Critical: PPSU has a narrow processing window. The conditioning station allows us to actively manage the preform temperature, preventing the outer skin from cooling too fast while keeping the core pliable. This is the secret to unbreakable bottles.

- Robust Injection Unit: PPSU is viscous. Our high-torque servo motors and specialized screw geometry ensure consistent melt without shear heat degradation.

- Oil-Free Molding Area: To maintain food-grade hygiene, our clamping and stretching units use electric or oil-free pneumatic drives to prevent contamination.

6. Process Flow: The 4-Station PPSU Cycle

Our One Step Injection Molding Machine follows a precise thermal journey:

Molten PPSU fills the cavity. Neck is formed.

Temp equalization. Prevents skin freezing.

Servo rod stretches. High pressure air forms bottle.

Robot removal. Bottle is ready for packing.

7. Engineer’s Field Notes: Global Success Cases

[South Korea] Premium Baby BrandChallenge: Replacing PC bottles due to BPA ban. Switched to PPSU but faced 20% scrap rate with 2-step molding due to black specks.

Solution: HGY200-V4 with specialized corrosion-resistant screw.

Result: Scrap reduced to <1%. Optical clarity matched glass.

[China] Top E-Commerce SellerChallenge: Needed a unique, ergonomic “S” shape bottle that was hard to mold evenly.

Solution: One Step Injection Blow Molding with differential heating conditioning.

Result: Perfect wall thickness distribution. Became a top-seller on Tmall.

[Vietnam] OEM ManufacturerChallenge: High energy costs running separate injection and blow machines for PA (Nylon) bottles.

Solution: Consolidated to One-Step ISBM.

Result: 35% energy savings. Reduced factory footprint by 50%.

[Germany] Glass Replacement ProjectChallenge: Parents wanted the durability of plastic but the look of amber glass.

Solution: PPSU processing on HGY-V4.

Result: A “break-proof glass” bottle that commanded a 30% price premium.

8. Value Analysis: PPSU ROI Breakdown

Molding PPSU is high-stakes. A single 160ml bottle retails for $20-$30 USD. Efficiency is key:

- Material Savings: With PPSU at $50/kg, eliminating sprues (runners) saves ~$0.50 per shot. Over 1 million cycles, that’s $500,000 in material savings alone.

- Defect Reduction: Lowering scrap rate from 10% (common in 2-step) to 1% (ISBM) saves massive amounts of expensive resin.

- Premium Positioning: High-quality ISBM bottles justify a “Premium” label, increasing profit margins significantly.

10. The Verdict: One-Step vs. Two-Step for PPSU

| Feature | Ever-power One-Step ISBM | Traditional Two-Step |

|---|---|---|

| Thermal History | Optimal (Single Heat) | Poor (Reheat degrades PPSU) |

| Visual Quality | Crystal Clear | Haze / Flow marks common |

| Material Waste | Near Zero | High (Cold runner waste) |

| Hygiene | Sterile Process | Preform handling risk |

11. Regulatory Compliance: BPA-Free & Safe

Baby products face the strictest regulations. Ever-power machines ensure you meet them:

- BPA/BPS Free: Our machines process Tritan, PPSU, and PA safely, ensuring compliance with FDA, EU 10/2011, and GB 4806 standards.

- Food Contact Safe: All polymer contact surfaces are SS316L or food-grade coated.

- Clean Manufacturing: Designed for low-dust, oil-free operation suitable for infant product manufacturing environments.

12. Brand Comparison: Ever-power vs. Market Leaders

Ever-power offers a smart alternative to high-cost Japanese machinery for the infant care market:

| High-Temp Capability | Matched capability (380°C+) with specialized heater bands and screws. |

| Mold Compatibility | Compatible with ASB-12N/12M style molds, allowing easy retrofitting. |

| Value | 40% Lower CAPEX. Significantly lowers the barrier to entry for new premium brands. |

*Disclaimer: Trademarks belong to their respective owners. Comparison for technical reference only.

13. FAQ: Expert Answers for Baby Bottle Makers

Can I process Tritan?

Yes. Tritan (Copolyester) is very similar to PET but requires specific drying and temperature profiles. Our machines are fully compatible with Eastman Tritan™.

What about drying PPSU?

PPSU is hygroscopic. It must be dried to <0.02% moisture. We supply high-temperature dehumidifying dryers integrated with the machine.

How many cavities for 240ml bottles?

For PPSU, we typically run 2 to 4 cavities to maintain precise thermal control. For PP feeding bottles, we can run up to 6 or 8 cavities.

Do you support mold design?

Yes. Baby bottle molds are complex (venting, threads). Our team designs molds specifically for PPSU flow characteristics.

Can I make handles?

No, handles are usually solid parts. ISBM makes the hollow bottle body. Handles are typically injection molded separately and assembled.

Is the machine difficult to clean?

Color changes in PPSU can be costly. Our screw design is self-cleaning to minimize purge material and downtime during color changes.

What is the warranty?

Standard 1 year on parts and labor. We offer extended warranties and service packages.

14. Critical Companion: Oil-Free Air Compressors

For ISBM Blow Molding Machine operations making baby products, air purity is non-negotiable.

We supply integrated Class 0 Oil-Free High-Pressure Air Compressors. Ensure that no trace of oil ever touches the inside of a baby bottle.

Launch Your Premium Baby Brand

Partner with Ever-power for safe, durable, and crystal-clear PPSU bottle production.