1. Engineering the “Glass-Like” Plastic: The Challenge of Tritan Molding

In my 20 years of engineering experience within the consumer goods sector, I have witnessed Tritan™ transform the hydration market. It offers the clarity of glass with the durability of steel, making it the perfect material for toddlers who drop everything. However, processing Tritan (Copolyester) is notoriously difficult compared to standard PET.

Tritan has a different crystallization behavior and higher viscosity. In traditional two-step blow molding, reheating a Tritan preform often leads to “pearlescence” (haze) or uneven wall thickness distribution, especially in complex shapes like sippy cups with handles or ergonomic curves. The material is unforgiving of temperature fluctuations.

This is where the One Step Blow Molding Machine (ISBM) technology excels. By integrating injection and blowing into a single thermal cycle, we bypass the reheating phase entirely. We maintain the Tritan preform in its optimal “rubbery” state, allowing for deep-draw stretching and complex shaping without stress whitening or optical defects.

2. Why Tritan Sippy Cups Need One-Step ISBM

Safety and durability are non-negotiable in the maternal and infant care industry. The One-Step process delivers on both fronts for Tritan applications:

- Complex Geometries: Sippy cups often feature integrated handles, wide necks, or “weighted straw” curves. One-Step ISBM allows for precise core rod design and conditioning to mold these non-standard shapes uniformly.

- Stress-Free Clarity: Tritan is prone to residual stress, which leads to cracking in the dishwasher. Our process minimizes shear stress during injection and allows for controlled cooling, resulting in a cup that stays clear after hundreds of wash cycles.

- Heavy Wall Thickness: To survive a drop from a high chair, sippy cups need walls 2-3x thicker than a water bottle. One-Step ISBM can blow thick-walled containers without the “gate haze” seen in other processes.

3. Core Industry Needs vs. Ever-power Technology Matching

| Sippy Cup Pain Point | Ever-power ISBM Solution | Technical Outcome |

|---|---|---|

| Leakage at Cap Threads deform or flash. |

Injection Molded Neck Direct cavity formation. |

Precision threads (±0.05mm) ensure a leak-proof seal with silicone valves. |

| Impact Failure Cups crack when dropped. |

Biaxial Orientation Control Servo stretching profile. |

Optimized molecular alignment maximizes Tritan’s impact resistance. |

| Optical Defects Flow marks or haze. |

Conditioning Station (V4) Active temp management. |

Crystal clear aesthetics comparable to glass, enhancing premium appeal. |

| High Material Cost Tritan is expensive. |

Hot Runner System Valve gate technology. |

Zero sprue waste. Near 100% material utilization. |

4. Typical Sub-Segment Applications

Our One Step PET Bottle Machine (configured for Copolyester) is versatile enough for the entire toddler range:

Training Cups with Handles

Cups where handles are either integrated (difficult) or assembled later. We ensure the body has the structural rigidity to support snap-on handles.

Straw Cups (Weighted)

Bottles with spherical bases or specific internal curves to allow a weighted straw to move freely. Requires precise internal geometry control.

Sports Spout Bottles

Larger 300ml-400ml bottles for older kids. High clarity is essential to see the liquid level and cleanliness.

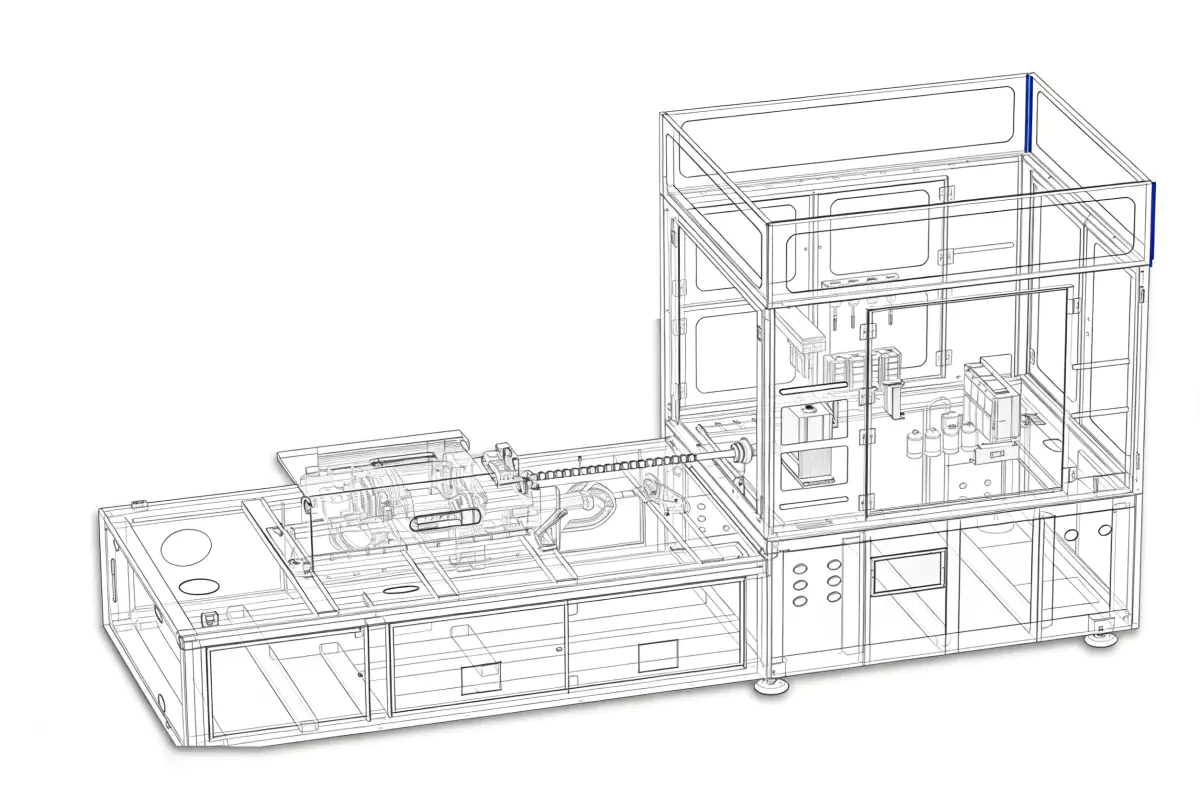

5. Ever-power Solution: The HGY200-V4 Powerhouse

For Tritan processing, you cannot cut corners. We recommend the HGY200-V4 (4-Station) machine.

Why the V4 for Tritan?

- Station 2 (Conditioning) is Mandatory: Tritan requires a specific temperature window to stretch without whitening. The V4’s conditioning station allows us to bring the injection-hot preform down to the exact stretching temperature uniformly, or differentially for non-round shapes.

- High-Torque Plasticizing: Tritan is viscous. Our specialized screw design ensures a homogeneous melt at lower RPMs to prevent shear heat degradation, which causes yellowing.

- Heavy-Duty Clamping: Blowing thick-walled cups requires higher blow pressures (up to 30 bar). Our robust toggle clamping unit ensures mold integrity and invisible parting lines.

6. Process Flow: The 4-Station Tritan Cycle

Our One Step Injection Molding Machine creates the perfect cup in four steps:

Molten Tritan forms the preform and precise neck threads.

Temperature equalization. Skin cooling for release, core retention for stretch.

Servo rod stretches. Clean air forms the durable cup body.

Automated removal. Cup is ready for assembly.

7. Engineer’s Field Notes: Global Success Cases

[USA] Leading Toddler BrandChallenge: “Weighted straw” cups were leaking because the neck ovalized during cooling in their previous 2-step process.

Solution: HGY200-V4 with servo-driven cooling mandrels in the conditioning station.

Result: 100% circularity achievement. Leakage complaints dropped to near zero.

[Australia] Eco-Friendly HydrationChallenge: Wanted to produce a “glass replacement” reusable water bottle for kids using Tritan Renew (recycled content).

Solution: One Step Injection Blow Molding optimized for recycled copolyesters.

Result: Successfully launched the first sustainable Tritan line in the region.

[China] OEM for Global RetailerChallenge: High scrap rate (15%) due to black specks and “burn” marks in Tritan molding.

Solution: Upgraded to Ever-power’s specialized Tritan screw and barrel set.

Result: Scrap rate reduced to <1%. Production efficiency increased by 20%.

[France] Boutique Baby GoodsChallenge: Needed a uniquely shaped, ergonomic cup that was impossible to reheat-blow evenly.

Solution: Differential heating in the ISBM conditioning station.

Result: A visually stunning, easy-grip cup that commanded a premium price.

8. Value Analysis: ROI for Tritan Production

Tritan resin is expensive (~$6-$8/kg). Efficiency is the key to profitability:

- Material Efficiency: Our hot runner system eliminates runners. For a 100g cup, saving 10g of runner waste per shot equals substantial savings annually.

- Energy Savings: Eliminating the reheat oven (needed in 2-step) cuts energy bills by ~40%.

- Quality Premium: Flawless, crystal-clear Tritan cups sell for 3x the price of standard PP cups.

10. The Verdict: One-Step vs. Two-Step for Tritan

| Feature | Ever-power One-Step ISBM | Traditional Two-Step |

|---|---|---|

| Optical Clarity | Superior (No Reheat Haze) | Risk of pearlescence |

| Impact Strength | High (Optimized Orientation) | Variable |

| Material Waste | Near Zero | High (Cold runners) |

| Surface Quality | Scratch-Free | Scratches from preform handling |

11. Regulatory Compliance: Safe for Baby

Importing baby products requires meeting stringent standards. Ever-power supports your compliance:

- BPA/BPS Free: Our machines process Tritan without contamination, ensuring compliance with FDA, EFSA, and GB standards.

- Heavy Metal Free: All machine components contacting the polymer are certified food-safe stainless steel.

- Clean Production: Oil-free pneumatic systems and electric drives prevent lubricant contamination of the cups.

12. Brand Comparison: Ever-power vs. Market Leaders

Ever-power offers a strategic advantage over expensive Japanese alternatives:

| Tritan Expertise | Proven screw designs and processing parameters specifically for Eastman Tritan™. |

| ROI | 40-50% Lower CAPEX compared to ASB/Aoki, with comparable bottle quality. |

| Flexibility | Can switch between Tritan, PP, and PPSU on the same machine (with screw/mold changes). |

*Disclaimer: Trademarks belong to their respective owners. Comparison for technical reference only.

13. FAQ: Expert Answers for Sippy Cup Makers

Do I need a special dryer for Tritan?

Yes. Tritan is hygroscopic and must be dried to <0.03% moisture to prevent hydrolysis and haze. We supply integrated desiccant dryers.

Can I mold handles directly?

No, ISBM molds the hollow cup body. Handles are typically solid parts injection molded separately and assembled, or snap-on rings are used.

What is the cycle time?

For a heavy-wall Tritan cup, typical cycle times are 15-20 seconds, allowing for proper cooling to prevent warping.

Is Tritan easier than PPSU?

Tritan processes at lower temperatures (~260°C) than PPSU (~360°C), making it slightly easier on the machine but more sensitive to moisture.

Can I use recycled Tritan?

Yes, Tritan Renew™ can be processed on our machines with excellent results, supporting your sustainability goals.

What mold steel do you use?

We use S136 stainless steel with a mirror polish to ensure the high-gloss finish required for Tritan products.

Do you provide training?

Yes, we provide comprehensive onsite training for your operators to master the specific processing parameters of Tritan.

14. Critical Companion: Oil-Free Air Compressors

For ISBM Blow Molding Machine operations making infant products, air purity is paramount.

We supply integrated Class 0 Oil-Free High-Pressure Air Compressors. Ensure that no trace of oil ever touches a baby’s drinking cup.

Create the Next Best-Selling Sippy Cup

Partner with Ever-power for crystal-clear, durable, and safe Tritan molding solutions.