1. Engineering the “Impossible” Grip: Challenges in Edible Oil Packaging

In the competitive edible oil market, the 1.8L to 5L bottle is king. Consumers demand a sturdy, ergonomic handle for pouring heavy liquids. However, integrating a handle into a PET bottle is one of the most difficult feats in blow molding.

Traditional two-step machines simply cannot blow a hollow handle. They require a separate plastic handle to be manually inserted or “clipped on,” which is labor-intensive and prone to detachment. Alternatively, extrusion blow molding (EBM) can make handles but lacks the crystal clarity and barrier properties of PET.

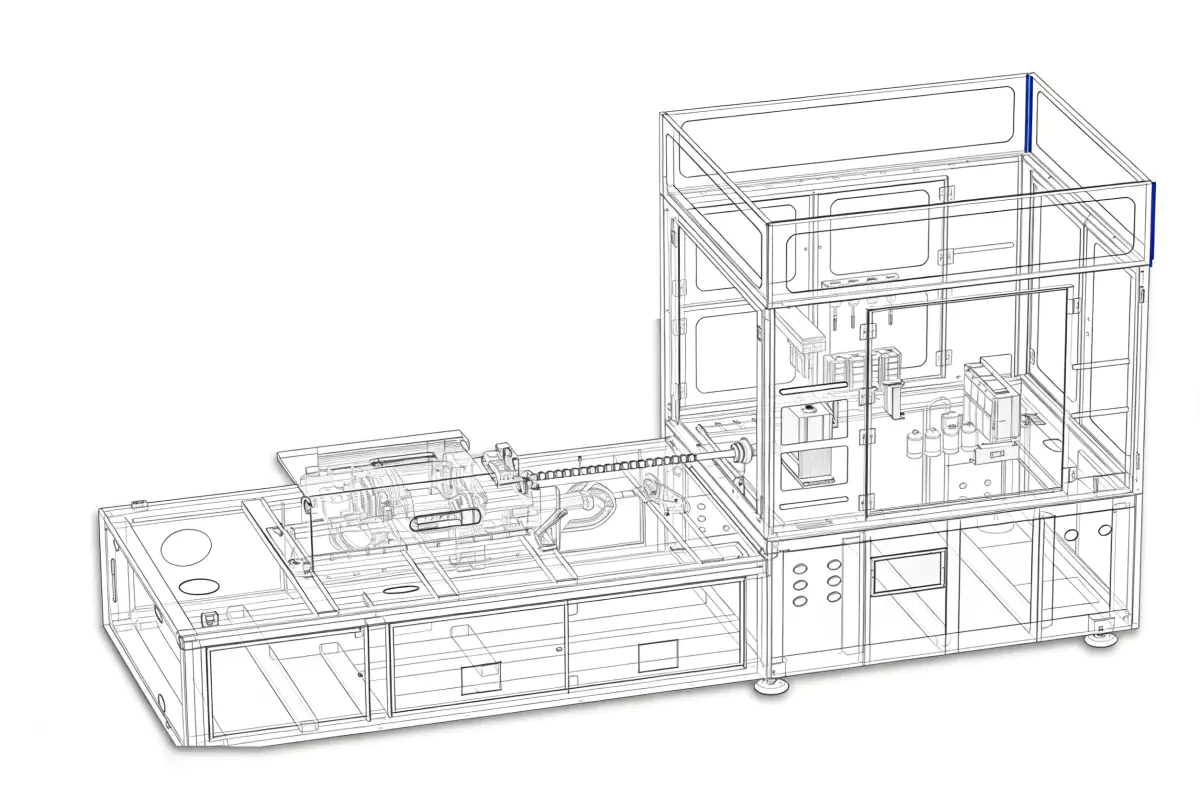

This is where the One Step Blow Molding Machine (ISBM) offers a revolutionary advantage. Using our specialized 4-station process, we can mold a preform with a “lug” or interface that allows for the insertion of a handle during the blowing process, or mold a solid handle integral to the neck. This results in a seamless, high-strength PET bottle that combines the clarity of glass with the utility of a jerrycan.

2. Why Edible Oil Bottles with Handles Need One-Step ISBM

For brands like Arawana, Fortune, or regional oil giants, the packaging must be robust, clear, and efficient to produce.

- Integrated Handle Strength: A handle inserted during the molding phase is mechanically locked into the PET structure. It cannot be pulled off, ensuring safety when consumers lift 5kg of oil.

- Material Savings: EBM processes generate significant flash (waste) at the handle and base. Our One-Step ISBM process is flash-free, saving up to 15% in material costs per bottle.

- Superior Clarity: Consumers want to see the purity of the oil. ISBM produces PET bottles with glass-like transparency, unlike the hazy PP/PE bottles from extrusion molding.

3. Core Industry Needs vs. Ever-power Technology Matching

| Oil Industry Pain Point | Ever-power ISBM Solution | Technical Outcome |

|---|---|---|

| Handle Insertion Complexity Manual insertion is slow/costly. |

Auto-Handle Feeding Robot Integrated into the blow station. |

Fully automated handle placement inside the mold before blowing. Zero labor cost. |

| Large Volume Molding 5L preforms are massive. |

HGY650-V4 High Tonnage 650kN Clamping Force. |

Enough power to inject and blow large preforms without flash or mold opening. |

| Oxidation of Oil Poor barrier properties. |

PET Barrier Capability Standard PET processing. |

10x better oxygen barrier than PE, extending shelf life of premium oils. |

| Production Speed Handles slow down cycle time. |

Parallel Action Control Servo-driven movements. |

Robot places handles while preform injects, minimizing cycle time penalty. |

4. Typical Sub-Segment Applications

Our One Step PET Bottle Machine (Large Format) serves the bulk liquid sector:

1.8L – 2L Cooking Oil

The standard family size. Features a “side handle” for easy one-handed pouring. Requires precise orientation of the preform to the handle cavity.

4L – 5L Bulk Oil

Heavy-duty containers. The handle must support 5kg+ dynamic loads. Often square or rectangular to maximize pallet density.

Soy Sauce & Vinegar

Large PET jugs for commercial kitchens. Clarity is key to distinguish product grades (light vs. dark soy).

5. Ever-power Solution: The HGY650-V4 Giant

For 5L bottles with handles, you need physical space and massive force. We recommend the HGY650-V4.

Why the HGY650-V4?

- Wide Platen for Handle Mechanisms: The mold platen is extra wide to accommodate the side-action sliders and robot arms required to insert handles into the blow mold. Standard machines simply don’t have the room.

- Heavy-Duty Injection: A 5L preform can weigh 90g-130g. Our injection unit is sized to plasticize this large volume of PET quickly and homogenously.

- Conditioning for Corners: Large square oil bottles suffer from thin corners. Our conditioning station allows differential heating to ensure the corners of a 5L jerrycan remain thick and impact-resistant.

6. Process Flow: The 4-Station Handle Cycle

Our One Step Injection Blow Molding process for handled bottles is a symphony of timing:

Preform is molded with a specific “lug” feature for the handle.

Temperature equalization. Orientation of the preform “lug” to face the handle cavity.

Mold opens, robot places handle. Mold closes. PET blows around the handle ends to lock it.

Bottle with integrated handle is ejected.

7. Engineer’s Field Notes: Global Success Cases

[China] Leading Edible Oil Brand (Fortune)Challenge: Replacing 5L PE jerrycans with clear PET. Needed a handle solution that didn’t slow down the line.

Solution: HGY650-V4 with dual-cavity handle insertion robot.

Result: 20% weight reduction compared to PE. Premium shelf appearance increased sales by 15%.

[Malaysia] Palm Oil ExporterChallenge: Shipping 5L bottles in containers. “Clip-on” handles were popping off during transit vibration.

Solution: One Step ISBM Machine with insert-molded handles.

Result: Zero handle failures. Handles are mechanically fused to the bottle body.

[Spain] Olive Oil ProducerChallenge: Wanted a 2L bottle with a side handle but found glass too heavy and expensive.

Solution: Custom PET design on HGY650-V4.

Result: 85% lighter than glass. Reduced carbon footprint significantly.

[Mexico] Institutional Food ServiceChallenge: High volume production of 4L Soy Sauce jugs. Extrusion blow molding was too slow.

Solution: 4-Cavity ISBM system.

Result: Doubled output per square meter of factory floor.

8. Value Analysis: ROI for 5L Oil Bottles

Moving from HDPE/PE to PET with integrated handles pays off:

- Resin Cost: PET is often cheaper per kg than HDPE, and you use less of it for the same strength.

- Cycle Speed: ISBM cycles for 5L are ~25 seconds. EBM cycles are ~45-60 seconds. You get double the output.

- Shelf Appeal: The clarity of PET allows consumers to see the product quality, often justifying a higher retail price point.

10. The Verdict: One-Step vs. Other Methods for Handled Bottles

| Feature | Ever-power One-Step ISBM | Extrusion Blow Molding (EBM) | Two-Step PET + Clip Handle |

|---|---|---|---|

| Clarity | Crystal Clear (PET) | Hazy / Opaque (PP/PE) | Clear |

| Handle Integrity | High (Insert Molded) | High (Integral) | Low (Can detach) |

| Material Waste | Zero Flash | High Flash (Handle/Tail) | Zero Flash |

| Cycle Time (5L) | ~25 sec | ~50 sec | ~20 sec (plus assembly) |

11. Regulatory Compliance: Safe Oil Packaging

Ever-power machines ensure your edible oil packaging meets global safety standards:

- Food Grade Materials: All contact parts are SS316L. Handles inserted are typically PP or PET, fully compatible with recycling streams.

- Drop Test Standards: Our bottles are engineered to pass standard 1.5m drop tests, ensuring no leakage during logistics.

- Migration Limits: Processing PET without degradation ensures acetaldehyde (AA) levels remain well below sensory thresholds for oil.

12. Brand Comparison: Ever-power vs. Market Leaders

Why choose Ever-power for large format bottles?

| Machine Size | Dedicated 650kN Platform. Many competitors stretch smaller machines to limit, causing wear. We built the HGY650 specifically for this heavy duty work. |

| Handle Technology | Proprietary robot integration for reliable handle placement at high speeds. |

| Cost Effectiveness | Lower initial investment allows for faster ROI in the low-margin commodity oil market. |

*Disclaimer: Trademarks belong to their respective owners. Comparison for technical reference only.

13. FAQ: Expert Answers for Oil Bottlers

Can I make square 5L bottles?

Yes. Square bottles are very common for oil to save shipping space. Our conditioning station ensures the corners are thick enough to support stacking.

Where do the handles come from?

You purchase pre-molded handles (usually PP) or mold them separately. They are loaded into a hopper on our machine and automatically fed into the blow mold.

What is the max bottle size?

The HGY650-V4 can produce bottles up to 12 Liters (2-cavity) or 5 Liters (4-cavity), depending on the specific dimensions.

Can I run recycled PET (rPET)?

Yes. rPET works well for oil bottles. We can equip the machine with crystallization dryers to handle rPET moisture levels.

How fast can it produce 5L bottles?

With a 4-cavity mold, output is approximately 600-800 bottles per hour, depending on bottle weight and handle complexity.

Is the handle leak-proof?

The handle insertion does not puncture the bottle. The PET blows around the handle grip points. The bottle integrity remains 100% intact.

What support do you offer?

We offer turnkey project support: bottle design, mold manufacturing, handle sourcing guidance, installation, and training.

14. Critical Companion: Oil-Free Air Compressors

For ISBM Blow Molding Machine food applications, you cannot risk oil mist from the compressor contaminating the edible oil bottle.

We supply integrated Class 0 Oil-Free High-Pressure Air Compressors to ensure the blowing air is as pure as your product.

Revolutionize Your Bulk Oil Packaging

Switch to high-efficiency, handle-integrated PET production with the HGY650-V4.