1. The Shift to Plastic Optics: Challenges in LED Bulb Manufacturing

In my 20 years of engineering within the lighting sector, the transition from glass incandescent bulbs to LED technology has been revolutionary. The critical component—the bulb cover or “globe”—has shifted from fragile glass to durable, light-diffusion Polycarbonate (PC). However, molding PC into a perfect sphere is fraught with technical difficulties.

Polycarbonate is a high-viscosity material that is difficult to stretch. Traditional Injection Molding (IM) produces heavy, thick-walled covers that trap heat and waste material. Standard 2-step blow molding often results in uneven wall thickness, particularly thinning at the “equator” of the bulb, which creates unsightly “hot spots” where the LED chips are visible.

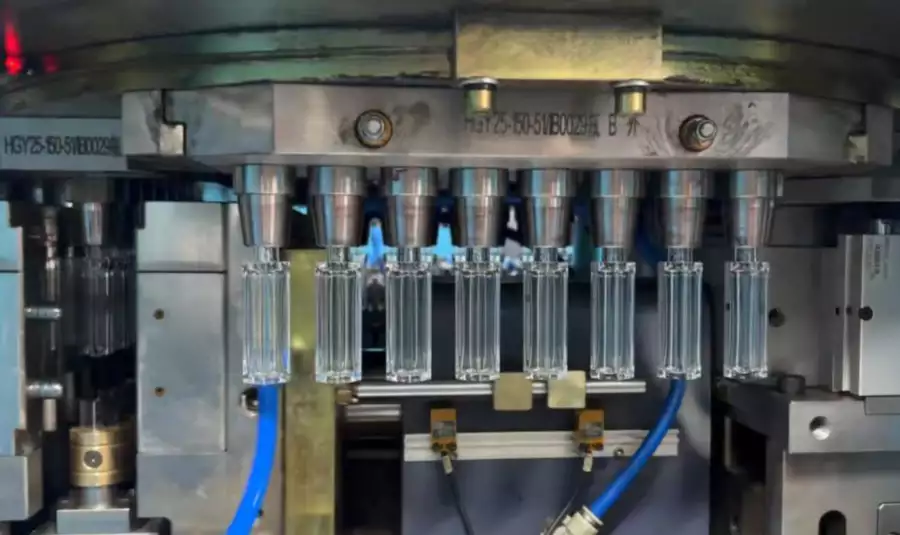

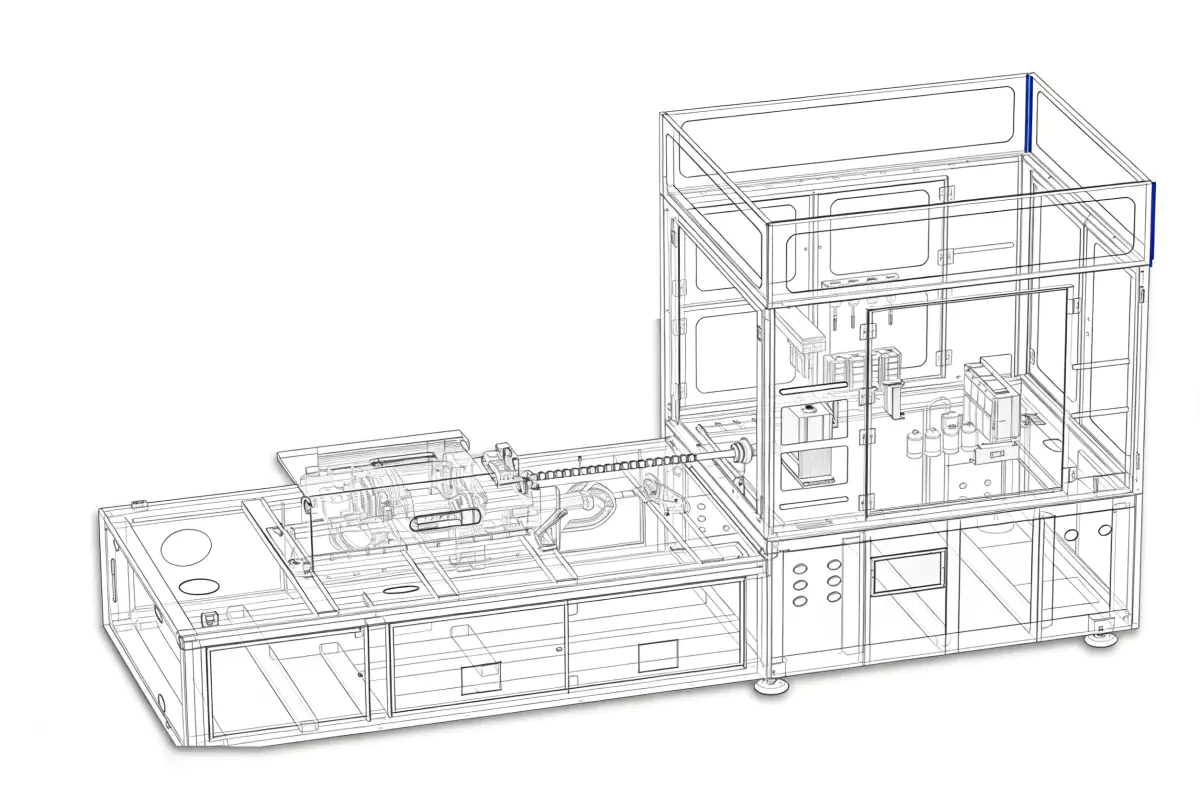

This is where the One Step Blow Molding Machine (ISBM) technology becomes the superior choice. By utilizing a 4-station process with active thermal conditioning, we can manipulate the PC preform to stretch evenly, creating a lightweight, high-diffusion cover with uniform wall thickness and invisible gate marks.

2. Why LED Bulb Covers Require One-Step ISBM

For lighting manufacturers producing A60, A70, or candle bulbs, ISBM offers critical advantages over Injection Molding or Glass blowing:

- Weight Reduction: ISBM allows for much thinner walls (0.8mm – 1.0mm) compared to Injection Molding (1.5mm – 2.0mm). This reduces material cost by up to 40% while maintaining impact strength.

- Optical Uniformity: The biaxial stretching process aligns the polymer chains, improving the mechanical strength and allowing for uniform dispersion of light diffusion additives without flow lines.

- Neck Precision: LED globes must snap-fit or screw onto the heat sink housing. ISBM injection molds the neck with high precision (±0.05mm), ensuring a secure assembly that passes torque and pull tests.

3. Core Industry Needs vs. Ever-power Technology Matching

| LED Industry Pain Point | Ever-power ISBM Solution | Technical Outcome |

|---|---|---|

| Hot Spots (Uneven Light) Caused by thin walls at the bulb equator. |

4-Station Conditioning (V4) Longitudinal temperature profiling. |

Compensates for stretch ratios in spherical shapes, ensuring consistent thickness from neck to dome. |

| Material Yellowing PC degrades with shear heat. |

Low-Shear Screw Design Optimized for PC viscosity. |

Gentle plasticizing prevents yellowing, maintaining high lumen output (light transmission). |

| Gate Mark Visibility Ugly sprue on top of the bulb. |

Hot Runner Valve Gate Direct injection. |

Near-invisible gate mark (< 1mm) at the top of the dome, requiring no post-trimming. |

| High Cycle Time PC cools slowly. |

Split Cooling Architecture Cooling in injection & conditioning. |

Cycle times reduced to 12-15 seconds for A60 bulbs. |

4. Typical Sub-Segment Applications

Our One Step PET Bottle Machine technology is adapted for Engineering Plastics (PC/PMMA) to serve the lighting industry:

A-Series Bulbs (A60, A70)

The standard household bulb shape. Requires perfect sphericity and seamless diffusion.

Candle & Globe Bulbs (C37, G45)

Decorative bulbs where aesthetics are paramount. The “flame” tip of a candle bulb is easily formed with ISBM.

T-Bulbs & High Wattage

Cylindrical covers for high-power industrial LED lamps. ISBM provides the structural integrity needed for larger dimensions.

5. Ever-power Solution: The HGY150-V4 Specialist

For Polycarbonate bulb covers, standard 3-station machines often fail to provide the necessary thermal control. We recommend the HGY150-V4 (4-Station).

Why the V4 for LED?

- Conditioning is Key: PC is tough. To stretch it without tearing or whitening, the preform temperature must be perfectly equalized. The V4’s conditioning station allows us to fine-tune the heat profile, ensuring the “shoulder” and “bottom” of the bulb stretch at different rates to create a uniform sphere.

- High Clamping Force: PC requires high injection pressure. The HGY150 offers 150kN clamping force to prevent flash on the neck, which is critical for IP-rated outdoor bulbs.

- Material Savings: The precision of the V4 allows you to mold bulbs with wall thicknesses as low as 0.6mm, saving significant material costs compared to the 1.5mm standard of injection molding.

6. Process Flow: The 4-Station PC Cycle

Our One Step Injection Molding Machine process for PC is optimized for optical quality:

PC is injected hot (280°C+). Neck and snap-fits are formed.

Temp equalization. Eliminates hot runner heat concentration at the gate.

Servo rod stretches. High pressure air forms the sphere.

Robot removal. Bulb is placed on cooling conveyor.

7. Engineer’s Field Notes: Global Success Cases

Solution: Installed a fleet of HGY150-V4 machines.

Result: Reduced bulb weight by 35% (Material savings). Increased output speed by 40% vs. Injection Molding.

Solution: One Step ISBM Machine with precise conditioning control.

Result: Achieved perfect wall thickness uniformity. Light diffusion is now completely even.

Solution: Molding UV-stabilized PC on HGY150-V4.

Result: Unbreakable covers produced in one step, replacing expensive imported parts.

Solution: Thin-wall ISBM blowing.

Result: Thinner walls improved signal transmission for smart home connectivity while saving material.

8. Value Analysis: ROI for LED Manufacturing

Switching from Injection Molding (IM) to ISBM for bulb covers is a financial game-changer:

- Material Savings: PC resin is expensive. Saving 5g per bulb on millions of bulbs adds up to hundreds of thousands of dollars annually.

- Cycle Time: ISBM cycles are faster than cooling a thick-walled injection molded part. Higher throughput per hour.

- Optical Value: Higher quality light diffusion allows you to use fewer or lower-bin LEDs to achieve the same lumen output.

10. The Verdict: ISBM vs. Injection Molding (IM) vs. EBM

| Feature | Ever-power One-Step ISBM | Injection Molding (IM) | Extrusion Blow Molding (EBM) |

|---|---|---|---|

| Wall Thickness | Thin & Uniform (0.8mm) | Thick (1.5mm+) | Uneven |

| Material Cost | Low | High | High (Flash waste) |

| Gate Mark | Tiny / Invisible | Large (Requires trim) | Large Pinch-off |

| Optical Clarity | High (No flow lines) | Medium (Flow lines) | Low |

11. Regulatory Compliance: Lighting Standards

Ever-power machines help you meet critical electrical and safety standards:

- UL 94 V-0 Flammability: Our machines process flame-retardant PC grades without degrading their chemical properties.

- Glow Wire Test: Uniform wall thickness ensures consistent results in thermal safety testing.

- RoHS / REACH: Oil-free molding zones prevent contamination, ensuring compliance with environmental directives.

12. Brand Comparison: Ever-power vs. Market Leaders

Ever-power offers a strategic advantage for the lighting industry:

| PC Processing | Specialized high-torque, low-shear screws designed specifically for optical PC. |

| CAPEX | 30-40% Lower Investment than Japanese machinery, improving lighting project margins. |

| Flexibility | Quick mold changes allow running A60, Candle, and Spot bulbs on the same machine. |

*Disclaimer: Trademarks belong to their respective owners. Comparison for technical reference only.

13. FAQ: Expert Answers for Lighting Manufacturers

Do I need a special dryer for PC?

Yes. PC is extremely hygroscopic. It must be dried to <0.02% moisture to prevent silver streaks and bubbles. We supply integrated high-temp dehumidifying dryers.

Can I mold the screw thread directly?

No, usually the PC bulb cover snaps onto a PBT housing which has the Edison screw. However, we mold the precise snap-fit undercut on the bulb neck.

How fast is the cycle?

For an A60 bulb, we achieve cycle times of 12-15 seconds depending on weight, which is significantly faster than standard injection molding.

Does the machine handle high temperatures?

Yes, PC processes at 280°C – 310°C. Our machines are equipped with ceramic heater bands and oil-cooled mold bases to handle this thermal load.

Can I produce flame retardant V0 bulbs?

Yes. Our screw geometry is designed to process FR-PC without degrading the flame retardant additives.

Is the gate mark visible?

We use a valve gate hot runner system. The gate vestige is minimal (< 1mm) and typically hidden at the very top of the dome, invisible when lit.

Do you provide training?

Yes, processing PC requires skill. We send engineers to train your staff on optimizing temperature profiles for optical clarity.

14. Critical Companion: Oil-Free Air Compressors

For ISBM Blow Molding Machine optical applications, air quality is paramount. Oil mist in the blowing air causes “fogging” inside the bulb cover.

We supply integrated Class 0 Oil-Free High-Pressure Air Compressors to ensure your LED covers remain perfectly clear and defect-free.

Light Up Your Production Line

Switch to the efficiency and optical precision of Ever-power ISBM technology.