1. Engineering the Unconventional: The Challenge of Complex Cosmetic Vials

In my 20 years of field engineering within the polymer processing industry, I have witnessed a definitive shift in the luxury packaging market. Brands are no longer satisfied with standard cylindrical bottles. To differentiate on the crowded shelves of Sephora or duty-free shops, designers are pushing for squares, triangles, polygons, and eccentric (off-center) necks. While these designs are visually arresting, they represent a significant manufacturing challenge, particularly for PET and PCTG materials.

The fundamental issue with molding a non-round bottle—say, a square perfume bottle—is material distribution. In a traditional process, the plastic stretches to the flat sides first and the corners last. Without precise intervention, this results in “dog-boning” (thick sides, razor-thin corners) or stress whitening (haze) at the edges. Standard Two-Step Reheat machines struggle here because they apply a uniform heat profile to a round preform, hoping physics will sort it out. It rarely does.

This is where the One Step Blow Molding Machine (ISBM) technology becomes not just an option, but a necessity. By utilizing a 4-station process that includes a dedicated Conditioning Station, we can manipulate the thermal history of the preform. We can keep the corners hot and cool the flat sides before blowing, ensuring uniform wall thickness even in the most aggressive geometries.

2. Why Complex Shapes Demand One-Step ISBM Technology

For high-end perfume and essential oils, the 4-Station ISBM Machine offers three critical advantages that Reheat Blow Molding (RBM) cannot match:

- 1. Differential Heating & Conditioning: Creating a square bottle from a round preform requires “preferential heating.” Our conditioning station uses core rods and conditioning pots to selectively add or remove heat from specific zones of the preform before it enters the blow mold. This allows the plastic to flow into corners without thinning.

- 2. Concentricity & Neck Precision: Perfume bottles often feature heavy metallic collars or snap-on pumps that require tolerance within ±0.05mm. In ISBM, the neck is injection molded and held by the lip cavity throughout the entire process. It never leaves the mandrel, guaranteeing absolute concentricity for eccentric (off-center) designs.

- 3. Surface Integrity (The “Crystal” Look): Luxury consumers expect plastic to look like glass. In a two-step process, preforms tumble in a hopper, accumulating micro-scratches. In our One-Step process, the preform is molded and blown without ever touching another surface, resulting in a pristine, flaw-free finish.

3. Industry Core Requirements vs. Ever-Power Technical Solutions

| Complex Shape Pain Points | Ever-Power ISBM Tech Solution | Engineering Outcome |

|---|---|---|

| Corner Thinning Square bottles break easily at corners. |

Conditioning Station (Station 2) Selective cooling of flat sides. |

Uniform wall thickness distribution (>1mm) in corners. |

| Off-Center Necks Preforms bend during stretching (Banana effect). |

Rotary Indexing Table Precision servo control. |

Preform orientation is mechanically locked; zero drift. |

| Haze / Stress Whitening Thick walls turn milky. |

Injection Temp Control Integrated hot runner & valve gates. |

Crystal clear PETG/PCTG heavy-wall bottles. |

| Mold Changeover Time High SKU mix in perfumery. |

Quick-Change Clamping Vertical clamping structure. |

Full changeover in < 3 hours for flexible production. |

Examples of polygonal and heavy-bottom bottles produced on Ever-Power machines.

4. Typical Sub-Segment Applications in Personal Care

Our One Step PET Bottle Machine capabilities extend to the most demanding geometric requirements:

Polygonal & Geometric Vials

Hexagonal, octagonal, or diamond-shaped bottles (15ml – 100ml) commonly used for niche perfumes. The sharp edges require precise material flow control to avoid stress cracking.

Eccentric (Off-Center) Bottles

Bottles where the neck is not aligned with the body’s central axis. Essential for ergonomic sprays or avant-garde designs. Only One-Step ISBM can guarantee the vertical alignment of the stretch rod in these cases.

Heavy-Wall “Glass Replacement”

Essential oil vials (5ml – 30ml) made from PCTG or PETG with wall thicknesses up to 4mm. These mimic the weight and feel of glass but offer shatter resistance for e-commerce shipping.

5. Ever-Power Solution Highlights: The HGY-V4 Advantage

For complex shapes, I strongly recommend the HGY-V4 Series (4-Station). While our 3-station machines are excellent for standard rounds, the 4-station architecture is the industry standard for difficult geometries.

Why the V4? The magic happens in Station 2 (Conditioning). Here, we strip the preform of its heat gradients. By using a temperature-controlled pot or core, we can create a thermal profile where the corners of a square bottle are kept pliable (hot) while the flat faces are cooled. This ensures that when the blow mold closes, the plastic stretches into the corners without over-thinning the flats.

Technical Specs:

- Servo Control: Utilizing 10 sets of Inovance/Weichi servo systems for precise movements.

- Clamping Force: Up to 400KN injection clamping to handle high-pressure molding of thick preforms.

- Energy Saving: Nano-infrared heating bands reduce energy consumption by ~30% compared to ceramic bands.

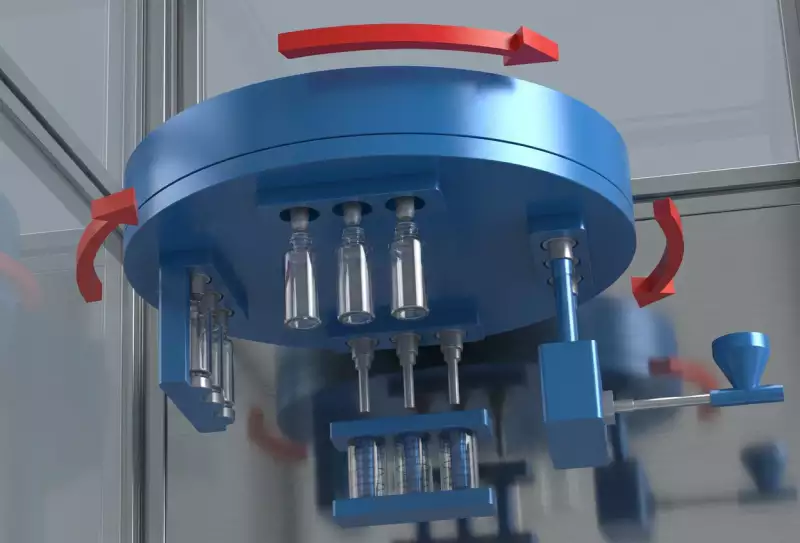

The 4-Station Cycle: Injection -> Conditioning -> Stretch Blow -> Eject.

6. Core Technical Speed Read: The 4-Station Process

Station 1: Injection

Molten PET/PCTG is injected into a cavity to form the preform. The neck finish is fully formed here to final tolerance.

Station 2: Conditioning (Tail Cutting/Temp Profiling)

The critical step for complex shapes. The preform is temperature-equalized. Differential heating profiles are applied to prepare for non-round stretching.

Station 3: Stretch Blow Molding

A servo-driven rod stretches the preform axially, while high-pressure air expands it radially against the cold mold walls to freeze the shape.

Station 4: Ejection

The finished bottle is stripped from the core rod by a robot or stripper plate, oriented upright for downstream packaging.

7. Engineer’s Field Notes: Global Success Stories

[France] Luxury Perfumery – The “Twisted” Polygon

Challenge: A Grasse-based perfumery needed a 100ml bottle with a 30-degree helix twist. 2-step molding caused unacceptable thinning on the outer radius.

Solution: HGY150-V4 with programmed conditioning profiles.

Result: Achieved uniform wall thickness (>1.2mm everywhere). “Ever-Power’s conditioning control saved this project.” – Pierre D., Production Director.

[Dubai, UAE] Heavy-Wall Oud Oil Vial

Challenge: Client wanted a 12ml vial that looked like solid crystal glass (heavy bottom) but was unbreakable for shipping.

Solution: 3-Station ISBM Machine optimized for thick-wall PCTG.

Result: Produced a vial with a 5mm thick base and zero crystallization haze.

[USA] Flat Pocket Sprayer

Challenge: Production of a credit-card style flat sanitizer bottle. Standard blow molding resulted in “dog-boning” (thick edges, thin center).

Solution: Custom oval core rods and conditioning pots on the HGY200-V4.

Result: Successfully molded millions of units for a major retail chain with <0.5% scrap rate.

[South Korea] Eccentric Serum Bottle

Challenge: An off-center neck design was causing the stretch rod to hit the preform wall in a competitor’s machine.

Solution: Ever-Power’s rigid servo-driven rotary table ensuring perfect alignment.

Result: 100% concentricity achieved, allowing for high-speed automated filling.

[Brazil] Essential Oil Dropper

Challenge: High breakage rates of glass bottles during transport to the Amazon region.

Solution: Transitioned to Amber PET using Ever-Power ISBM.

Result: Shipping damage reduced to zero; freight costs reduced by 60% due to lighter weight.

Our state-of-the-art facility spanning 20,000 sqm in Qingyuan City.

8. Customer Value & ROI Analysis

Investing in a dedicated ISBM Blow Molding Machine for complex shapes yields significant financial returns:

- Energy Efficiency: Eliminating the reheat oven (used in 2-step) reduces energy consumption by ~40%. For a machine running 24/7, this saves approx. $15,000 – $20,000 USD annually.

- Material Savings: One-step process generates minimal waste (sprues are often reground inline). The “Glass-to-Plastic” conversion reduces shipping weight by ~85%.

- Premium Pricing: The ability to mold unique, non-round shapes allows brands to charge a premium. A custom polygon bottle can command 3x the price of a standard round bottle.

10. One-Step vs. Two-Step: The Cosmetic Packaging Verdict

| Feature | Ever-Power One-Step (ISBM) | Traditional Two-Step (Reheat) |

|---|---|---|

| Complex Shapes | Excellent (Conditioning Station) | Poor (Uniform reheat limits shaping) |

| Surface Quality | Pristine (No contact) | Scratched (Preform tumbling) |

| Energy Efficiency | High (Retains Injection Heat) | Low (Requires massive reheating) |

| Space Requirement | Compact (One machine) | Large (Injection + Reheat Blower) |

| Hygiene | Sterile (Closed loop) | Risk of contamination in storage |

11. [Global] Regulatory Compliance & Safety

Importing machinery for high-value cosmetic production requires strict adherence to international standards. Ever-Power machines are built to facilitate smooth customs clearance and safe operation:

- ✅ CE Marking (Europe): Compliant with Machinery Directive 2006/42/EC and Low Voltage Directive. Essential for our clients in France and Italy.

- ✅ UL Standards (USA/Canada): We utilize UL-listed electrical components (Schneider, Rockwell) to ensure compliance with North American safety codes.

- ✅ Food Contact Safety: All screws, barrels, and molds are manufactured from high-grade stainless steel, compliant with FDA 21 CFR 177.1630 for PET contact.

12. Brand Comparison: Ever-Power vs. The Giants

We respect the pioneers like ASB and Aoki. However, Ever-Power offers a strategic advantage for agile manufacturers:

| Technology Level | Comparable 4-Station Rotary Architecture. Compatible with many ASB-12M style molds. |

| Investment Cost | 40-50% Lower CAPEX than Japanese counterparts. Faster ROI. |

| Lead Time | Average 60-90 days vs. 6-12 months for competitors. |

*Disclaimer: ASB and Aoki are trademarks of their respective owners. References are for technical comparison only.

13. FAQ: Expert Answers for B2B Buyers

Can I use Recycled PET (rPET) for cosmetic bottles?

Yes, our machines are optimized for rPET. However, for high-clarity perfume bottles, we recommend blending or using high-grade rPET to avoid yellowing. Our screws are designed to handle rPET melt characteristics.

What is the mold changeover time?

For the HGY-V4 series, a complete mold change (Injection, Conditioning, Blow, Lip) takes approximately 3-4 hours with a trained team. We provide a mold crane and quick-change tools.

Do I need a chiller?

Yes. To prevent crystallization (haze) in thick-walled perfume bottles and reduce cycle time, powerful cooling is required for the injection mold and conditioning station. We can help size this for you.

Can I produce oval and square bottles on the same machine?

Absolutely. The machine remains the same; you only need to change the molds and the conditioning pots to match the new shape.

What is the mold life?

Our molds are made from high-grade S136 stainless steel. With proper maintenance, they are rated for over 3 million shots.

Do you provide installation?

Yes, we send senior engineers to your facility for installation, commissioning, and training. We don’t leave until you are running production at the guaranteed cycle time.

What materials can I run?

The HGY series handles PET, PETG, PCTG, PC, PP, and Tritan. We have specific screw designs for different materials.

How do you handle spare parts?

We use global standard components (Yaskawa, Parker, Yuken) available locally in most countries. For proprietary parts, we ship via DHL/FedEx within 24 hours.

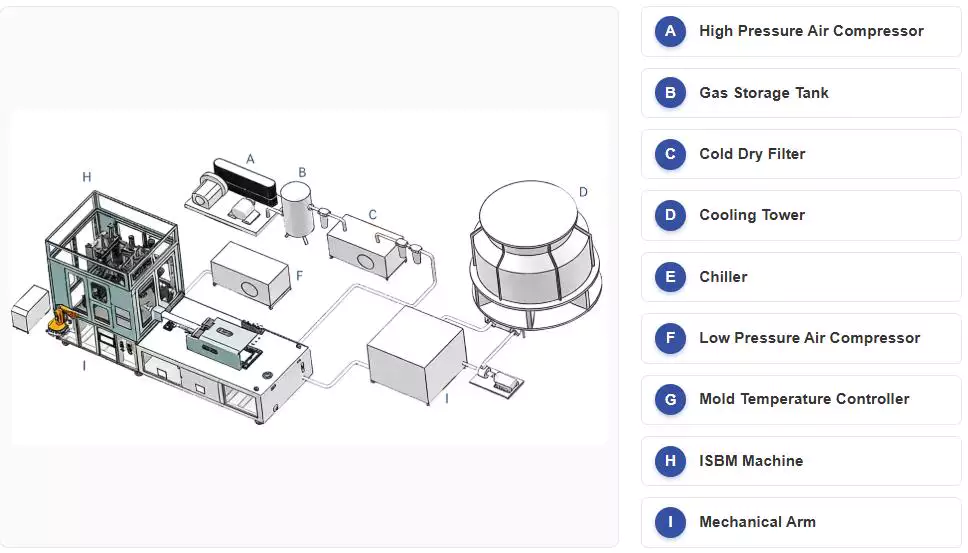

14. Essential Companion: Oil-Free Air Compressors

For high-quality Injection Stretch Blow Molding Machine operations, the quality of your compressed air is paramount. Even a trace of oil in the blowing air can ruin the clarity of a perfume bottle or cause rejection in food-grade applications.

We manufacture and supply integrated Oil-Free High-Pressure Air Compressors (3.0-4.0 MPa) specifically calibrated for our ISBM machines, ensuring your packaging remains contaminant-free.

Ready to Reshape Your Cosmetic Line?

Don’t let complex designs limit your potential. Partner with the experts who understand the physics of complex shape molding.