1. The Shift from Glass to PET: Challenges & Opportunities in Oral Liquid Packaging

In my 20 years of engineering experience in the pharmaceutical packaging machinery sector, the most significant trend I have witnessed is the aggressive migration from Type III Glass to PET for oral liquids, syrups, and suspensions. While glass has a long history, its drawbacks—breakage on filling lines, heavy shipping costs, and safety hazards for end-users—are undeniable.

However, producing PET bottles for pharmaceuticals isn’t just about blowing plastic. It requires precise neck finishes for Child-Resistant Caps (CRC) and Tamper-Evident bands. Traditional “Two-Step” methods often struggle with neck dimensional stability and hygiene control. This is where One Step Blow Molding Machine (ISBM) technology becomes the standard-bearer. By forming the preform and blowing the bottle in one sterile, integrated machine, we ensure that the container meets the rigorous demands of the pharma industry without the “human touch” contamination risks associated with handling cold preforms.

2. Why Oral Liquid Manufacturing Needs One-Step ISBM

For syrup bottles (typically 60ml to 200ml), the production volume is massive, but the margins are tight. Manufacturers need a solution that balances high speed with high precision.

- Neck Precision for CRC: Child-resistant caps require tight thread tolerances. ISBM injection molds the neck, guaranteeing a perfect seal every time, unlike extrusion blow molding which requires trimming.

- Surface Quality: Amber PET bottles must be defect-free to ensure proper light barrier performance. The one-step process prevents preforms from scratching each other, maintaining the aesthetic and functional integrity of the container.

- Energy Efficiency: Reheating cold preforms in a two-step process consumes massive amounts of energy. Our ISBM Machine technology utilizes the residual heat from injection, significantly lowering the carbon footprint per bottle.

3. Core Pharma Needs vs. Ever-power Technology Matching

| Industry Requirement | Ever-power ISBM Solution | Technical Implementation |

|---|---|---|

| Mass Production Speed Millions of units needed annually. |

6-Station High Speed Architecture (Model HGYS280-V6) |

Splitting cooling and conditioning steps to slash cycle times to under 10 seconds. |

| Light Protection Sensitive syrups degrade in UV. |

Homogeneous Amber Mixing High L/D Screw Design. |

Specialized screw geometry ensures perfect dispersion of amber masterbatch without streaks. |

| Hygiene & Safety No heavy metals or contamination. |

Oil-Free & Stainless Contact Food-grade contact parts. |

All polymer flow paths use S136 stainless steel; electric drives reduce hydraulic oil risk. |

| Weight Consistency Consistent fill volumes. |

Servo Injection Control Closed-loop feedback. |

Shot weight deviation < 0.2%, ensuring accurate internal volume for filling lines. |

4. Typical Sub-Segment Applications

While “Oral Liquid” is the broad category, our machines are optimized for specific bottle types:

Cough Syrup Bottles (60ml – 150ml)

The standard Amber PET bottle replacing glass. Requires high clarity and uniform wall thickness to prevent “paneling” during vacuum filling.

Paediatric Suspension Bottles

Wide-mouth designs for easy pouring. Our Injection Stretch Blow Molding Machine handles wide neck finishes (28mm+) without deformation.

Rectangular “Flat” Bottles

Oval or flat profiles often used for OTC medications. The conditioning station in our machines allows for differential heating to mold these non-round shapes perfectly.

5. Ever-power Solution: The HGYS280-V6 Powerhouse

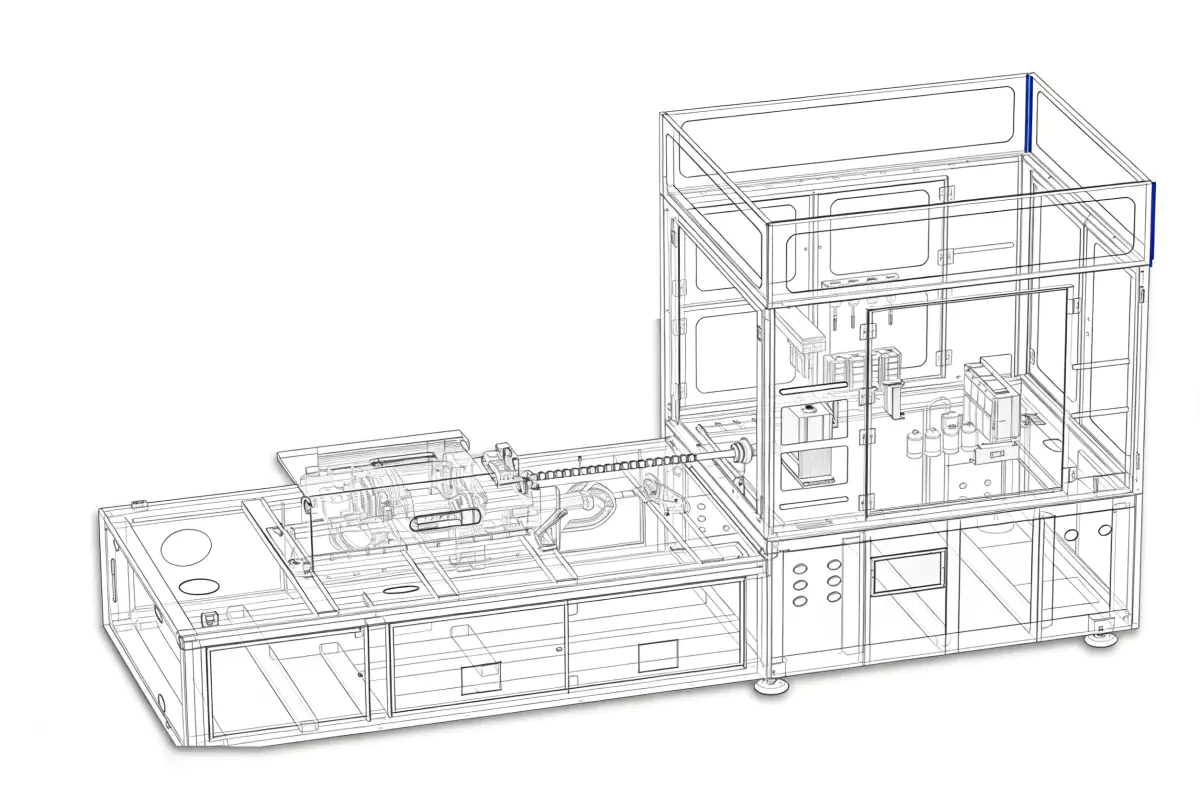

For the massive volumes required in the pharmaceutical syrup market, a standard 3-station machine is often too slow. We recommend the HGYS280-V6 (6-Station High Speed).

Why the 6-Station Architecture?

The 6-station design splits the cooling and conditioning processes, which are the bottlenecks in PET molding. This allows for:

- Cycle Times Reduced by 40%: By balancing the time spent in injection and cooling, we achieve cycles compatible with high-speed downstream filling lines.

- High Cavitation: We can run up to 8 or 10 cavities for smaller bottles, producing thousands of units per hour.

- Stable Thermal History: The extra stations allow for precise temperature equilibration, ensuring that the Amber PET material stretches evenly without stress whitening.

6. Process Flow: The 6-Station Efficiency

Our One Step Injection Blow Molding process (HGYS-V6) optimizes every second:

7. Engineer’s Field Notes: Global Success Cases

[India] Major Cough Syrup ManufacturerChallenge: Replacing heavy glass bottles for a popular 100ml cough syrup. Glass breakage on the filling line was causing 5% downtime.

Solution: Installed two HGYS280-V6 lines running Amber PET.

Result: Zero breakage. Shipping weight reduced by 85%. Line efficiency improved to 98%.

[USA] Generic Pharma PackerChallenge: Needed a flexible machine to run 60ml, 120ml, and 200ml bottles with fast changeovers.

Solution: One Step PET Bottle Machine (Model V4) with Quick-Change Mold System.

Result: Changeovers reduced from 8 hours to 3 hours, allowing for agile production planning.

[Indonesia] Vitamin Syrup BrandChallenge: High humidity caused hygiene issues with stored preforms in their old 2-step process.

Solution: Switched to Ever-power One-Step technology.

Result: Eliminated the preform storage stage entirely. Bio-burden levels dropped significantly.

[Vietnam] Traditional MedicineChallenge: Wanted to modernize packaging from glass to plastic but maintain a “premium” heavy feel.

Solution: Heavy-wall PET molding using our machine’s precise cooling control.

Result: A plastic bottle that feels like glass but doesn’t break.

[Egypt] Contract ManufacturerChallenge: Electricity costs were eating into margins.

Solution: Replaced hydraulic extrusion blowers with Servo-driven ISBM.

Result: 40% reduction in energy consumption per bottle.

8. Value Analysis: ROI of Glass-to-Plastic Conversion

Let’s analyze the Return on Investment for a typical 100ml Syrup Bottle production line:

- Weight Savings: A 100ml glass bottle weighs ~100g. A PET equivalent weighs ~12g. This 88% weight reduction slashes logistics costs immediately.

- Breakage Elimination: Glass lines typically budget 2-3% for breakage/loss. With PET ISBM, this drops to near zero, saving product and cleanup time.

- In-House Production: Manufacturing bottles in-house with an ISBM Blow Molding Machine costs approximately 40% less than purchasing ready-made sterile bottles.

10. The Verdict: One-Step vs. Two-Step for Oral Liquids

| Feature | Ever-power One-Step (ISBM) | Traditional Two-Step |

|---|---|---|

| Neck Quality | Superior (Injection Molded) | Variable (Reheated, potential deformation) |

| Hygiene | Sterile Cycle (No Handling) | Risk (Dust on stored preforms) |

| Aesthetics | Scratch-Free | Preforms tumble & scratch in hopper |

| Footprint | Compact (1 Machine) | Large (Injection + Reheat Blower) |

| Energy | High Efficiency | Low (High reheat cost) |

11. Compliance & Standards: Meeting Pharma Regulations

Pharmaceutical packaging is highly regulated. Ever-power supports your compliance journey:

- USP <661>: Our machines process PET grades compliant with USP standards for light transmission and chemical resistance.

- FDA 21 CFR 177.1630: All machine components contacting the polymer are certified safe for food/drug contact.

- Cleanroom Compatibility: Our electric and hybrid machines are designed with enclosed shrouding to minimize particle generation, suitable for ISO 8 environments.

12. Brand Comparison: Ever-power vs. Market Leaders

Ever-power provides a compelling alternative to Japanese incumbents like ASB or Aoki for mass-market pharma applications:

| Capability | Matched 6-Station Architecture. Same High-Speed Logic. |

| Investment | 30-45% Lower CAPEX. Ideal for generics manufacturers where cost control is paramount. |

| Service | Global installation teams with faster response times for parts. |

*Disclaimer: Trademarks belong to their respective owners. Comparison for technical reference only.

13. FAQ: Expert Answers for Pharma Plant Managers

Can I run Amber PET?

Yes. Our screw design is optimized for mixing masterbatch. We ensure homogeneous color distribution for consistent UV protection.

What is the output for 100ml bottles?

On the HGYS280-V6, with an 8-cavity mold, you can achieve upwards of 3,500 – 4,000 bottles per hour, depending on bottle weight.

Can I make Child-Resistant necks?

Absolutely. The injection mold is machined to the exact specification of your CRC cap, ensuring pass-fail torque tests are met 100%.

Do you sell the molds?

Yes, we design and manufacture high-precision S136 stainless steel molds in-house, ensuring a perfect match with our machine.

Is the machine difficult to operate?

Our PLC interface is designed for ease of use. We provide 1-2 weeks of onsite training to ensure your operators are proficient.

Can I process PP (Polypropylene)?

Yes, the machine can process PP. However, PP requires different conditioning parameters than PET. We can set up the machine for both materials.

How stable is the process?

With servo-driven injection and clamping, the process capability index (Cpk) is very high, ensuring consistent bottle weight and dimensions.

What about spare parts?

We use standard components (Inovance, Yuken, etc.) available globally. We also keep a stock of critical spares for immediate dispatch.

14. Essential Companion: Oil-Free Air Compressors

For pharmaceutical One Step Molding Machine operations, the blowing air must be contaminant-free. Oil in the air stream is a critical failure.

We supply integrated Oil-Free High-Pressure Air Compressors designed to ISO 8573-1 Class 0 standards, ensuring that the air touching your medicine bottles is as pure as the medicine itself.

Upgrade Your Pharmaceutical Packaging Line

Switch to the efficiency, safety, and precision of Ever-power ISBM technology.