1. Engineering the “Impossible” Preform: Challenges in Wide-Mouth Molding

In my 20 years of experience with food packaging machinery, wide-mouth jars (neck diameter > 60mm) have always been the “heavyweights” of the industry. Whether for peanut butter, candy, dried fruits, or pickles, these jars require a massive preform. The projected area of a 100mm neck preform is enormous, creating immense separation forces during the injection phase.

Traditional two-step machines struggle here. Why? Because injecting a “pancake” preform (wide and short) and then reheating it evenly is a thermal nightmare. The edges overheat while the center stays cold. Furthermore, standard machines lack the clamping tonnage to keep the mold closed against the injection pressure of such a large surface area, leading to flash (defects) on the sealing surface.

This is where the One Step Blow Molding Machine (ISBM) proves its dominance. By using a specialized high-tonnage clamping unit (up to 650kN) and a 4-station process, we inject the preform and condition it immediately. We don’t need to reheat a cold, awkward preform; we simply manage the heat it already has. This results in perfect material distribution for large-diameter jars.

2. Why Wide-Mouth Food Jars Demand One-Step ISBM

For brands like Walmart, Costco, or regional food giants, the jar must be tough, clear, and perfectly sealed.

- Clamping Force is King: Wide necks generate huge opening forces. Our HGY650 series offers injection clamping forces that prevent mold separation, ensuring flash-free necks for airtight induction sealing.

- Bottom Strength: Large jars carry heavy loads (e.g., 2kg of honey). The “push-up” or base of the jar needs to be thick and rigid. One-Step ISBM allows precise cooling of the gate area, preventing the bottom from sagging or cracking under load.

- Stackability: Retail shelves demand jars that stack perfectly. Our process ensures the neck and base are concentric, so jars align vertically without wobbling.

3. Core Industry Needs vs. Ever-power Technology Matching

| Food Industry Pain Point | Ever-power ISBM Solution | Technical Outcome |

|---|---|---|

| Sealing Surface Defects Flash prevents foil sealing. |

High-Tonnage Clamping (650kN) Hydraulic/Servo hybrid. |

Zero flash on the landing zone (neck rim). 100% induction seal reliability. |

| Wall Thickness Variation Thin spots cause collapse. |

Core Rod Conditioning Internal cooling channels. |

Uniform wall thickness even in square or rectangular “pantry pack” jars. |

| Hot Fill Deformation Jars shrink when filled hot. |

Heat-Set Blowing Option Heated blow molds. |

PET jars capable of withstanding filling temperatures up to 85°C. |

| Slow Production Thick preforms cool slowly. |

4-Station Split Cooling Conditioning station aids cooling. |

Cycle times reduced by 30% compared to standard injection molding. |

4. Typical Sub-Segment Applications

Our One Step Injection Molding Machine (Large Format) is the backbone of the bulk food aisle:

Peanut Butter & Spread Jars

PET jars replacing glass. Requires excellent oxygen barrier and rigid walls to withstand vacuum capping.

Confectionery (Candy) Jars

High-clarity “display” jars. Often square or hexagonal to maximize shelf facing. Requires sharp corner definition.

Dried Fruit & Nut Canisters

Large volumes (1L – 3L) with wide openings (80mm – 110mm) for hand access. Requires high top-load strength for stacking.

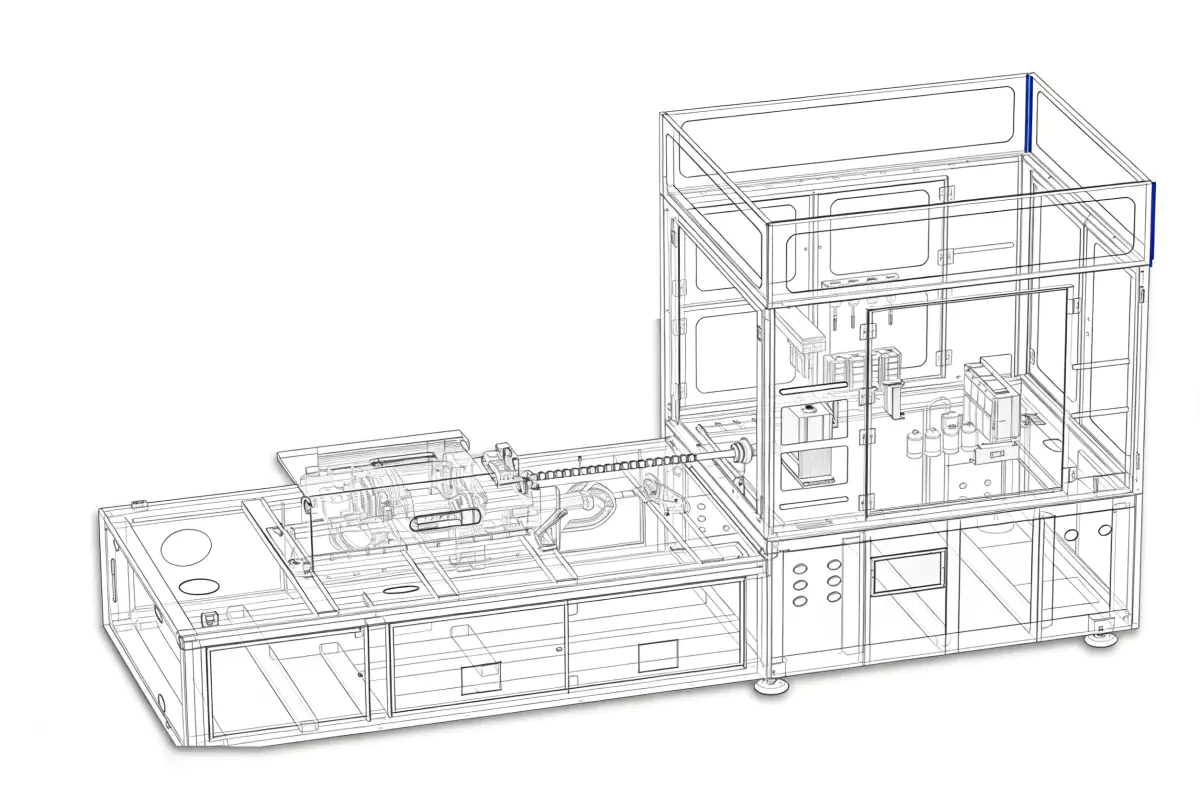

5. Ever-power Solution: The HGY650-V4 Titan

For wide-mouth jars, size matters. We recommend the HGY650-V4. This machine is a beast, specifically built to handle the projected area forces of large preforms.

Why the HGY650-V4?

- Massive Clamping Force: With 650kN (approx. 65 tons) of injection clamping force, it holds the mold shut against the enormous internal pressure of injecting a 100mm+ diameter preform. This eliminates “flashing” (plastic leakage) which destroys the neck seal.

- Heavy-Duty Turntable: Large preforms are heavy. Our servo-driven turntable is reinforced to index heavy loads (e.g., 4 cavities of 80g preforms) smoothly without vibration.

- Wide Platen Area: The mold platen is physically larger to accommodate the wide spacing required for multi-cavity wide-mouth molds.

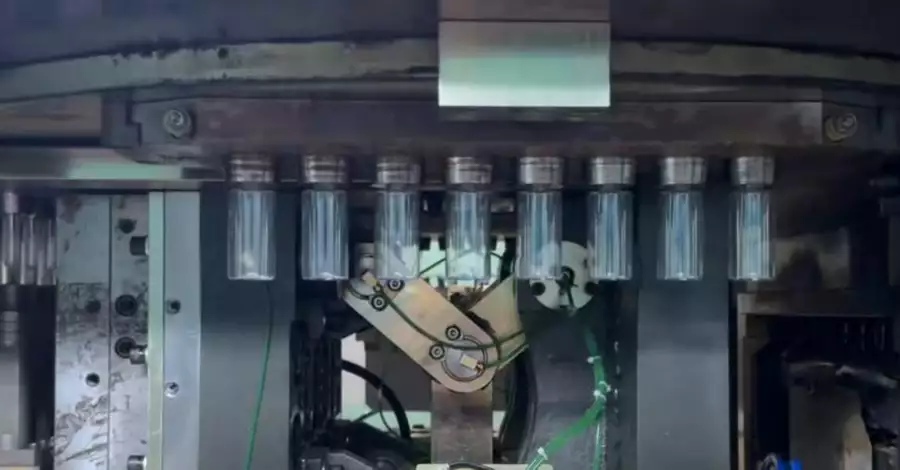

6. Process Flow: The 4-Station Heavy Duty Cycle

Our One Step PET Bottle Machine creates robust jars with precision:

High-pressure fill. Neck and heavy base are formed.

Core cooling. Critical to solidify the thick base/gate.

Low stretch ratio blowing. Forms the wide body.

Mechanical stripping. Jar is placed on conveyor.

7. Engineer’s Field Notes: Global Success Cases

[USA] Major Nut Butter BrandChallenge: Switching from glass to PET. The 83mm neck required for the jars was causing flash issues on their existing smaller ISBM machines.

Solution: Installed HGY650-V4. The high clamping force solved the flashing immediately.

Result: 100% seal integrity on the induction line. Freight costs dropped 60%.

[Turkey] Honey ProducerChallenge: Honey is heavy. The bottom of their PET jars was sagging, causing “rockers” on the shelf.

Solution: One Step Injection Blow Molding with intensive base cooling in the conditioning station.

Result: Flat, rigid bases that could hold 1kg of honey without deformation.

[China] Spicy Sauce (Chili Oil)Challenge: Hot filling at 80°C caused standard PET jars to shrink.

Solution: Implemented “Heat-Set” blow molds on the HGY650-V4.

Result: Heat-resistant PET jars that replaced glass, reducing breakage in the factory.

[Spain] Olive & Pickle JarsChallenge: Needed a wide 100mm opening for hand-packing olives.

Solution: Custom large-format molds.

Result: High-efficiency production of wide-mouth jars with perfect clarity to show off the product quality.

8. Value Analysis: ROI for Food Jars

In high-volume food packaging, pennies count. Here is the ISBM advantage:

- Weight Optimization: ISBM allows for “light-weighting” the jar body while keeping the neck rigid. Saving 2g per jar on 10 million jars = 20,000kg of resin saved.

- Logistics: Square ISBM jars pack 20% more product per pallet than round glass jars.

- Safety Savings: No glass shards on the production line means no batch contamination recalls due to breakage.

10. The Verdict: One-Step vs. Two-Step for Wide Mouth

| Feature | Ever-power One-Step ISBM | Traditional Two-Step |

|---|---|---|

| Neck Flatness | Superior (No distortion) | Variable (Reheat warping) |

| Wall Uniformity | Excellent (Controlled heat) | Poor (Uneven reheat of wide preform) |

| Bottom Strength | High (Thick gate control) | Medium |

| Stacking Strength | High (Concentric) | Medium |

11. Regulatory Compliance: Food Safety First

Ever-power machines are built for the food industry:

- FDA / EU 10/2011: All resin contact parts (screws, barrels) are food-grade stainless steel or coated alloys.

- Lubricant Free: We use H1 food-grade lubricants where necessary and design oil-free molding zones to prevent contamination.

- Energy Star: Our servo systems reduce power consumption, aligning with corporate sustainability goals.

12. Brand Comparison: Ever-power vs. Market Leaders

Ever-power provides a robust alternative to high-priced competitors for bulk food packaging:

| Clamping Tonnage | 650kN Standard. Many competitors offer only 500kN in this class, leading to flash issues on large jars. |

| Cost of Ownership | Significantly lower spare parts cost and maintenance requirements. |

| Customization | We specialize in custom wide-mouth molds and neck finishes (e.g., 63mm, 83mm, 110mm, 120mm). |

*Disclaimer: Trademarks belong to their respective owners. Comparison for technical reference only.

13. FAQ: Expert Answers for Food Packers

What is the max neck size?

The HGY650-V4 can handle neck finishes up to 120mm diameter, covering almost all standard wide-mouth food jars.

Can I do Hot Fill?

Yes, but it requires a specific mold configuration (Heat Set) and usually a slightly heavier bottle weight. We can equip the machine for this.

Can I run PP (Polypropylene)?

Yes. PP wide-mouth jars are popular for their moisture barrier. The machine can run PP with parameter adjustments.

What about square jars?

Square jars are our specialty. The conditioning station allows us to shape the preform temperature to blow perfect corners.

Do you supply the molds?

Yes, we design and manufacture high-quality molds in-house, ensuring the cooling channels are optimized for wide-mouth production.

How many cavities?

For a 1-liter jar (83mm neck), we typically run 4 to 6 cavities. For smaller jars, up to 8 or 10 cavities.

Is installation included?

We send a team of engineers to install, commission, and train your staff until you are reaching target production speeds.

14. Critical Companion: Oil-Free Air Compressors

For ISBM Blow Molding Machine food applications, you cannot risk oil contamination in the jar.

We supply integrated Class 0 Oil-Free High-Pressure Air Compressors to ensure your jars meet all food safety standards.

Scale Up Your Food Packaging Production

Get the robustness and speed of the HGY650-V4 for your wide-mouth jars.