Description

One Step Blow Molding Machine HGY150-V4-EV: Premium 4-Station ISBM Technology for PET Containers

Engineered by Ever-power | High-Efficiency 4-Station Architecture | Japanese ASB Compatible

Engineering Overview: The Evolution of 4-Station Precision

In my twenty years of field experience optimizing thermoplastic processing lines, I have witnessed the shift from simple mass production to high-precision, aesthetic-driven manufacturing. The HGY150-V4-EV stands at the forefront of this evolution. As a dedicated One Step Blow Molding Machine, it integrates the entire bottle-making process—injection, temperature conditioning, stretching/blowing, and ejection—into one seamless, energy-efficient cycle.

Unlike standard 3-station units, the HGY150-V4-EV features a critical Temperature Conditioning Station. This allows for precise thermal manipulation of the preform before blowing, ensuring uniform wall thickness even for complex geometries or heavy-wall cosmetic jars. Engineered by Ever-power to be fully compatible with Japanese ASB-12M molds, this machine offers top-tier performance at a significantly more accessible entry point, maximizing your ROI without compromising on the ISBM Machine quality standards required by global pharmaceutical and cosmetic brands.

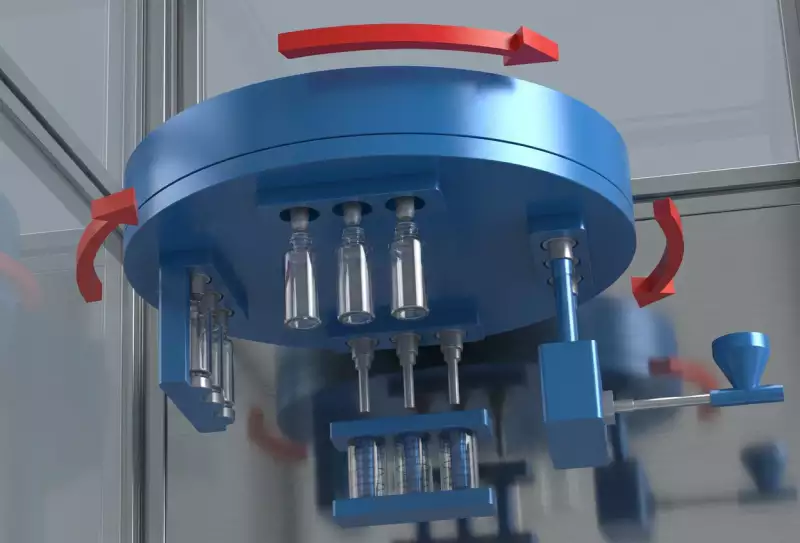

Figure 1: The Ever-power HGY150-V4-EV 4-Station ISBM Unit

1. Technical Standard Configuration

Reliability in continuous manufacturing stems from component quality. The HGY150-V4-EV integrates a global supply chain of top-tier components to ensure stability under 24/7 operation.

| System / Component | Brand / Specification |

|---|---|

| Servo System | Using 10 sets of servo motor control screws |

| Servo Motor Power | 102.8KW (Inovance / WEICHI) |

| Control System (PLC) | Inovance / MIRLE |

| Turntable Rotation | Yaskawa Servo (Japan) or WEICHI Servo + TSUNTIEN Reducer (Taiwan) |

| Blow Molding Structure | Dual servo motor mold clamping system with high-pressure compensation |

| High Pressure Valve | Parker (USA) |

| Pneumatic Cylinder | Airtak |

| Temperature Control | Integrated Control Box (High accuracy, stable) |

| Screw Heating | Nano-far-infrared energy-saving heating ring (10KW) |

| Lead Screw | NSK (Japan) |

| Mold Compatibility | Compatible with Japanese ASB-12M mould |

| Total Power | 112.8 KW |

2. Machine Parameters & Capabilities

The HGY150-V4-EV is designed for heavy-duty performance with a focus on precision clamping and rapid cycle times. Note the substantial clamping force and generous stroke lengths.

| Parameter | Value |

|---|---|

| Screw Diameter | 50mm (Standard) / Options available |

| Theoretical Injection Capacity | 392g |

| Injection Clamping Force | 150 KN |

| Blowing Clamping Force | 200 KN (Single Side) |

| Temp. Regulating Core Stroke | 250 mm |

| Temp. Regulating Barrel Stroke | 230 mm |

| Upper Mold Stroke | 250 mm |

| Lower Mold Stroke | 205 mm |

| Take-out Stroke | 170 mm |

| Blow Core Stroke | 250 mm |

| Machine Dimensions (L*W*H) | 5200 x 1800 x 3300 mm |

| Machine Weight | 7 Tons |

Production Capacity Specifications

| Product Quantity (Cavities) | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Max Bottle Diameter (mm) | 118 | 80 | 66 | 56 | 54 | 45 | 28 | 26 |

| Max Bottle Height (mm) | 210 | 210 | 210 | 150 | 150 | 150 | 100 | 100 |

| Neck Diameter (mm) | 83 | 62 | 48 | 38 | 32 | 25 | 17 | 15 |

| Max Bottle Volume (ml) | 2500 | 1500 | 900 | 400 | 250 | 100 | 30 | 20 |

| Max Bottle Weight (g) | 130 | 65 | 43 | 32 | 26 | 22 | 18 | 16 |

Core Technology: 4-Station ISBM Process Flow

The One Step Injection Blow Molding technology is an art of thermal management. The HGY150-V4-EV executes this in four distinct stages on a rotary table, ensuring the PET retains its Intrinsic Viscosity (IV) for maximum strength and clarity.

1. Injection Station

Molten PET is injected into the cavity to form the preform. The neck finish is molded to exact tolerances (crucial for leak-proof sealing), while the body remains hot.

2. Temperature Conditioning

The V4 Advantage: The preform is transferred to a conditioning pot. Here, temperature is homogenized—cooling the skin or heating the core—to create the perfect thermal gradient for stretching.

3. Stretch & Blow

A stretch rod extends the preform axially, followed by high-pressure air expanding it radially against the mold. This biaxial orientation imparts superior mechanical strength and clarity.

4. Ejection

The finished bottle is stripped from the lip mold and automatically conveyed out. The process is touchless, ensuring hygiene for pharmaceutical applications.

Why Choose the HGY150-V4-EV? Core Advantages

- ✓

Advanced Servo Control: With 10 sets of servo motor control screws, the machine offers unparalleled precision in movement and injection pressure control. - ✓

ASB Compatibility: We understand the market. If you have existing tooling for ASB-12M machines, they can be mounted on the HGY150-V4-EV with minimal to no modification, saving you tens of thousands in tooling costs. - ✓

Energy Efficiency: Utilizing Nano-far-infrared heating rings and servo-driven systems, we reduce energy consumption significantly compared to traditional hydraulic systems. - ✓

Invisible Parting Lines: Our 200KN clamping force with high-pressure compensation ensures that even heavy-wall cosmetic jars have a seamless finish.

Strategic Analysis: One-Step vs. Two-Step Systems

| Comparison Dimension | Ever-power One-Step ISBM | Traditional Two-Step (Reheat) |

|---|---|---|

| Process Flow | Resin -> Bottle (Integrated) | Resin -> Preform -> Cool -> Reheat -> Bottle |

| Energy Efficiency | High (Uses latent injection heat) | Low (Wastes energy reheating preforms) |

| Surface Quality | Flawless (No scuffing/scratches) | Risk of transport scratches on preforms |

| Applicable Materials | PET, PETG, PC, Tritan, PPSU, PP | Mostly limited to PET/PP |

| Space Requirement | Compact (One machine) | Large (Requires Injection unit + Blow unit + Storage) |

| Hygiene Level | Medical/Food Grade (Touchless) | Standard (Exposed to open air storage) |

Industry Applications

Cosmetics & Personal Care

The One Step PET Bottle Machine excels in producing heavy-wall cream jars, mascara containers, and high-clarity lotion bottles. The lack of reheating ensures zero haze, providing a glass-like aesthetic essential for luxury branding.

Pharmaceuticals

From eye drops to pill bottles, the HGY150-V4-EV ensures neck precision for child-resistant caps. The enclosed process meets strict GMP requirements.

Specialty Beverages

Ideal for mini-liquor bottles (50ml) and premium juice containers where unique shapes and precise volumes are required.

Power System Selection Summary: Ever-power vs. Competitors

Many clients ask how we compare to Japanese giants like ASB or Aoki. The answer is simple: We offer 95% of the capability at 60% of the cost.

The Ever-power Guarantee: Our HGY150-V4-EV is built with the same global components (Yaskawa, Parker, NSK) found in more expensive machines. We don’t cut corners on hardware; we optimize manufacturing overhead to pass savings to you.

ROI Case: Medium Beverage Plant

Switching from purchasing preforms to an in-house One Step Blow Molding Equipment setup:

- Material Savings: Pellet cost is ~25% lower than preform cost.

- Energy Savings: Elimination of reheat tunnel saves ~35% electricity.

- Payback Period: Typically 12-16 months for a single HGY150-V4-EV unit running 2 shifts.

[North America] Extreme Condition Resilience

For our clients in varying climates, the HGY150-V4-EV is equipped with an advanced hydraulic oil cooling loop. Whether you are operating in the humid summers of Florida or the freezing winters of Minnesota, the system maintains a stable oil temperature of 40-50°C, ensuring consistent clamp pressure and cycle times.

Compliance: CE Certified, UL Electrical Standards compliant upon request.

Engineer’s FAQ

Can I use my existing ASB-12M molds?

Yes, absolutely. The HGY150-V4-EV is engineered with the same platen layout and mounting points. You can transfer your legacy molds directly to our machine.

What materials can this machine process?

Beyond standard PET, it effectively handles PETG, PC (Polycarbonate), PP (Polypropylene), and Tritan. The screw geometry can be customized for specific resins.

What is the maintenance schedule?

We recommend a hydraulic oil change every 5,000 hours and a daily check of the lubrication points. The auto-lube system handles most moving parts.

Global Case Studies: Engineer Field Notes

USA: Pharmaceutical Vials

“Replaced 3 older units. The cleanroom footprint reduction was massive.” – Production Manager, NJ

Brazil: Premium Cosmetics

“The conditioning station allows us to mold heavy-bottom jars without defects.” – Plant Lead, São Paulo

Germany: Bio-resins

“Handling PLA was difficult until we tried the V4’s precise temp control.” – Engineer, Munich

India: Baby Bottles

“Producing PPSU baby bottles requires high heat. The V4 handles it perfectly.” – Director, Mumbai

Vietnam: Beverage

“Reliable output in a hot climate. The oil cooling is robust.” – Tech Lead, Hanoi

Swipe to view more client success stories

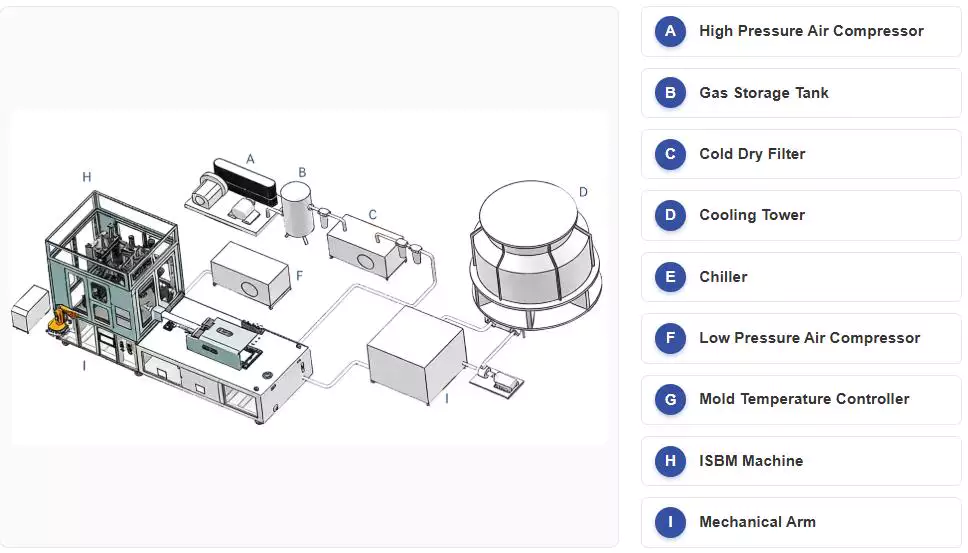

Complete Your Production Line

Ensure contamination-free air for your blowing process with our specialized Oil-Free Air Compressor.

Ready to Upgrade Your Production?

Don’t let outdated machinery hold you back. Experience the precision of the HGY150-V4-EV and see why global manufacturers trust Ever-power.