Description

One Step Blow Molding Machine HGY200-V4: Heavy-Duty 4-Station ISBM Technology

Engineered by Ever-power | 300KN Injection Clamping Force | ASB-12M Mold Compatible

Engineering Overview: The Heavy-Duty Precision Solution

In my twenty years of field experience commissioning production lines for high-viscosity polymers and complex container geometries, I have found that stability is the cornerstone of profitability. The HGY200-V4 is not just another machine; it is Ever-power’s heavy-duty answer to the market’s demand for a robust One Step Blow Molding Machine capable of handling higher cavitation and heavier shot weights.

Operating on a sophisticated 4-station rotary indexing system, this machine integrates Injection, Temperature Conditioning, Stretch-Blowing, and Ejection into a continuous thermal loop. Unlike smaller units, the HGY200-V4 boasts a massive 300KN injection clamping force, making it the ideal ISBM Machine for producing thick-walled cosmetic jars, large-volume pharmaceutical bottles, and intricate PCTG/PETG containers that require substantial injection pressure. Crucially, it is engineered for full compatibility with Japanese ASB-12M molds, allowing you to upgrade your production capabilities without rendering your existing tooling investment obsolete.

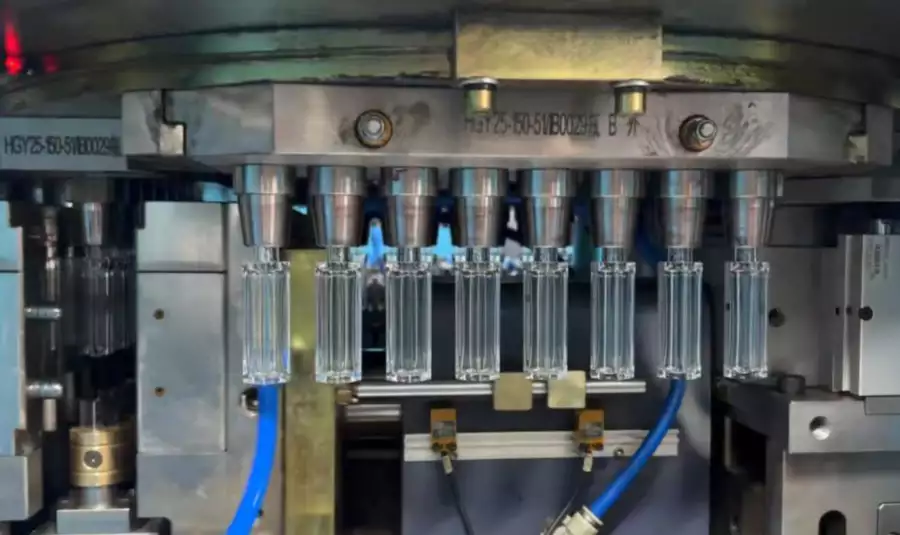

Figure 1: The Ever-power HGY200-V4 Heavy Duty 4-Station Unit

1. Technical Standard Configuration

The HGY200-V4 is built to run 24/7. We utilize a “Best-in-Class” component strategy, integrating top-tier global suppliers to ensure that the Mean Time Between Failures (MTBF) exceeds industry standards.

| System / Component | Brand / Specification |

|---|---|

| Servo System | Using 3 sets of servo pump systems |

| Servo Motor Power | 49.2KW (Inovance / WEICHI) |

| Control System (PLC) | Inovance / MIRLE (High processing speed) |

| Turntable Rotation | Yaskawa Servo (Japan) or WEICHI Servo + TSUNTIEN Reducer (Taiwan) |

| Blow Molding Structure | Hydraulic cylinder or Dual servo motor mold damping system with high-pressure compensation |

| High Pressure Valve | Parker (USA) |

| Pneumatic Cylinder | Airtak |

| Temperature Control | Integrated Control Box (or optional built-in system) |

| Hydraulic Control | YUKEN (Taiwan) Pressure Control Valve |

| Screw Heating | Nano-far-infrared energy-saving heating ring (10KW) |

| Injection Unit Control | Single Cylinder Control (Hydraulic or Servo Melt Motor) |

| Mold Compatibility | Compatible with Japanese ASB-12M mould |

| Total Power | 59.2 KW |

2. Machine Parameters & Performance Metrics

The HGY200-V4 is defined by its power. With 300KN of injection clamping force, it provides the “muscle” needed for high-cavitation molds and dense materials.

| Parameter | Value |

|---|---|

| Screw Diameter | 50mm (Standard) / Options: 40, 55, 60mm |

| Theoretical Injection Capacity | 310g (Range: 188 – 480 cm³) |

| Injection Clamping Force | 300 KN (High Pressure) |

| Blowing Clamping Force | 200 KN (Single Side) |

| Upper Mold Stroke | 460 mm |

| Lower Mold Stroke | 210 mm |

| Temp. Regulating Core Stroke | 250 mm |

| Temp. Regulating Barrel Stroke | 250 mm |

| Take-out Stroke | 175 mm |

| Blow Core Stroke | 300 mm |

| Blow Mold Stroke | 75 + 75 mm |

| Oil Tank Volume | 300 L |

| Machine Dimensions (L*W*H) | 4800 x 2000 x 3200 mm |

| Machine Weight | 13 Tons |

Production Capacity Specifications (Cavities vs. Dimensions)

| Product Quantity (Cavities) | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|

| Max Bottle Diameter (mm) | 118 | 110 | 105 | 100 | 68 | 65 | 48 | 45 | 38 | 26 |

| Max Bottle Height (mm) | 210 | 150 | 100 | |||||||

| Neck Diameter (mm) | 83 | 68 | 68 | 65 | 55 | 50 | 40 | 25 | 23 | 15 |

| Max Bottle Volume (ml) | 2500 | 1500 | 900 | 750 | 350 | 200 | 100 | 50 | 30 | 20 |

| Max Bottle Weight (g) | 150 | 65 | 45 | 35 | 30 | 28 | 25 | 20 | 15 | 10 |

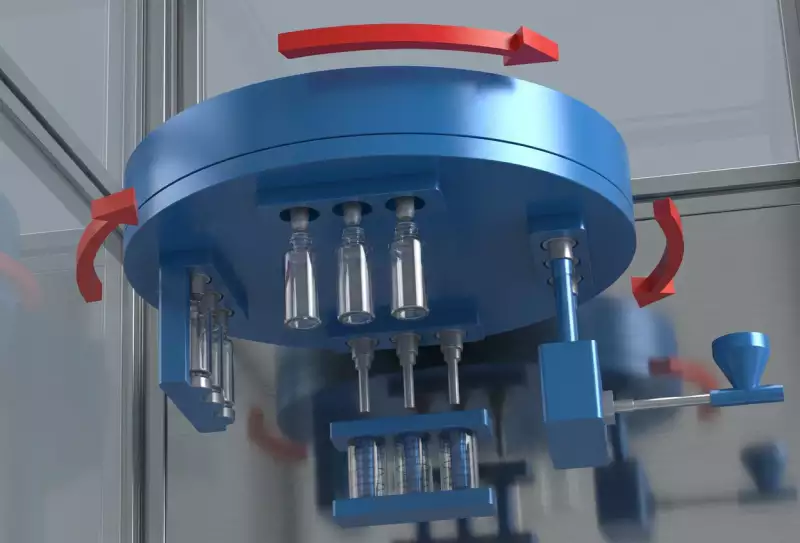

Core Technology: 4-Station ISBM Process Flow

The One Step Injection Blow Molding technology used in the HGY200-V4 is a masterclass in thermal management. By using a rotary table to move the cores between four distinct stations, we ensure the PET retains its Intrinsic Viscosity (IV) for maximum strength and clarity, without the energy loss of reheating.

1. Injection Station

Molten PET is injected into the cavity. The 300KN clamping force ensures no flash on the parting lines, even with high-pressure injection required for thin-wall preforms or complex necks.

2. Conditioning Station

The V4 Advantage: The preform is transferred to a conditioning pot. This station homogenizes the temperature—cooling the skin or heating the core—creating the perfect thermal gradient for stretching.

3. Stretch & Blow

A stretch rod extends the preform axially, followed by high-pressure air expanding it radially. The 200KN Blow Clamping Force ensures the mold remains perfectly closed during high-pressure expansion.

4. Ejection

The finished bottle is stripped from the lip mold and automatically conveyed out. The process is touchless, ensuring hygiene for pharmaceutical applications.

Why Choose the HGY200-V4? Core Advantages

- ✓

Massive Clamping Force: With 300KN (Injection) and 200KN (Blow), this machine handles difficult materials (like PC or thick PETG) that smaller machines cannot process without flashing. - ✓

ASB-12M Compatibility: We understand the market. If you have existing tooling for ASB-12M machines, they can be mounted on the HGY200-V4 with minimal to no modification, saving you tens of thousands in tooling costs. - ✓

Energy Efficiency: Utilizing Nano-far-infrared heating rings and advanced servo pumps, we reduce energy consumption by up to 40% compared to traditional hydraulic systems. - ✓

High Cavitation Capability: Capable of running up to 12 cavities for small vials (20ml), drastically increasing output per cycle compared to standard 4-8 cavity machines.

Strategic Analysis: One-Step vs. Two-Step Systems

| Comparison Dimension | Ever-power One-Step ISBM | Traditional Two-Step (Reheat) |

|---|---|---|

| Process Flow | Resin -> Bottle (Integrated) | Resin -> Preform -> Cool -> Reheat -> Bottle |

| Energy Efficiency | High (Uses latent injection heat) | Low (Wastes energy reheating preforms) |

| Surface Quality | Flawless (No scuffing/scratches) | Risk of transport scratches on preforms |

| Applicable Materials | PET, PETG, PC, Tritan, PPSU, PP | Mostly limited to PET/PP |

| Space Requirement | Compact (One machine) | Large (Requires Injection unit + Blow unit + Storage) |

| Hygiene Level | Medical/Food Grade (Touchless) | Standard (Exposed to open air storage) |

Industry Applications

High-End Cosmetics

The One Step PET Bottle Machine excels in producing heavy-wall cream jars and mascara containers. The high clamping force ensures the thick bases are molded without sink marks.

Pharmaceuticals

From eye drops to wide-mouth pill bottles, the HGY200-V4 ensures neck precision for child-resistant caps. The enclosed process meets strict GMP requirements.

Baby Care (PPSU/PC)

The machine’s robust screw and heating system are perfect for processing high-temperature engineering plastics like PPSU for baby bottles, which require high injection pressure.

Power System Selection Summary: Ever-power vs. Competitors

Many clients ask how we compare to Japanese giants like ASB or Aoki. The answer is simple: We offer 95% of the capability at 60% of the cost.

The Ever-power Guarantee: Our HGY200-V4 is built with the same global components (Yaskawa, Parker, NSK) found in more expensive machines. We don’t cut corners on hardware; we optimize manufacturing overhead to pass savings to you.

ROI Case: Medium Beverage Plant

Switching from purchasing preforms to an in-house One Step Blow Molding Equipment setup:

- Material Savings: Pellet cost is ~25% lower than preform cost.

- Energy Savings: Elimination of reheat tunnel saves ~35% electricity.

- Payback Period: Typically 12-18 months for a single HGY200-V4 unit due to high output capacity (up to 12 cavities).

[North America] Extreme Condition Resilience

For our clients in varying climates, the HGY200-V4 is equipped with an advanced hydraulic oil cooling loop. Whether you are operating in the humid summers of Florida or the freezing winters of Minnesota, the system maintains a stable oil temperature of 40-50°C, ensuring consistent clamp pressure and cycle times.

Compliance: CE Certified, UL Electrical Standards compliant upon request.

Engineer’s FAQ

Can I use my existing ASB-12M molds?

Yes, absolutely. The HGY200-V4 is engineered with the same platen layout and mounting points. You can transfer your legacy molds directly to our machine.

What is the max bottle size for this machine?

In a single cavity configuration, it can produce bottles up to 2.5 Liters. In a 12-cavity setup, it is optimized for small vials up to 20-30ml.

What is the maintenance schedule?

We recommend a hydraulic oil change every 5,000 hours and a daily check of the lubrication points. The auto-lube system handles most moving parts.

Global Case Studies: Engineer Field Notes

USA: Pharmaceutical Vials

“Replaced 3 older units. The cleanroom footprint reduction was massive.” – Production Manager, NJ

Brazil: Premium Cosmetics

“The conditioning station allows us to mold heavy-bottom jars without defects.” – Plant Lead, São Paulo

Germany: Bio-resins

“Handling PLA was difficult until we tried the V4’s precise temp control.” – Engineer, Munich

India: Baby Bottles

“Producing PPSU baby bottles requires high heat. The V4 handles it perfectly.” – Director, Mumbai

Vietnam: Beverage

“Reliable output in a hot climate. The oil cooling is robust.” – Tech Lead, Hanoi

Swipe to view more client success stories

Complete Your Production Line

Ensure contamination-free air for your blowing process with our specialized Oil-Free Air Compressor.

Ready to Upgrade Your Production?

Don’t let outdated machinery hold you back. Experience the precision of the HGY200-V4 and see why global manufacturers trust Ever-power.