Description

One Step Blow Molding Machine HGY50-V3-EV: Precision 3-Station ISBM Technology for PET Containers

Engineered by Ever-power | 20+ Years of Polymer Processing Expertise

Engineering Overview: Redefining Production Efficiency

The HGY50-V3-EV is not just a machine; it is a strategic asset for manufacturers aiming for the premium segment of the packaging market. This One Step Blow Molding Machine integrates the injection of the preform and the blowing of the bottle into a single, compact unit. This eliminates the reheating phase required in two-step processes, thereby preserving the Intrinsic Viscosity (IV) of the PET and ensuring crystal-clear transparency and superior mechanical strength.

The core advantage of the HGY50-V3-EV lies in its 3-station architecture. Unlike 4-station machines that consume more floor space and energy, our V3 design optimizes the thermal retention of the preform. By utilizing the residual heat from the injection process, we drastically reduce energy consumption while maintaining a cycle time that rivals larger industrial units. It is the ideal ISBM Machine for producing high-quality cosmetic containers, pharmaceutical bottles, and premium beverage packaging where surface finish and dimensional accuracy are non-negotiable.

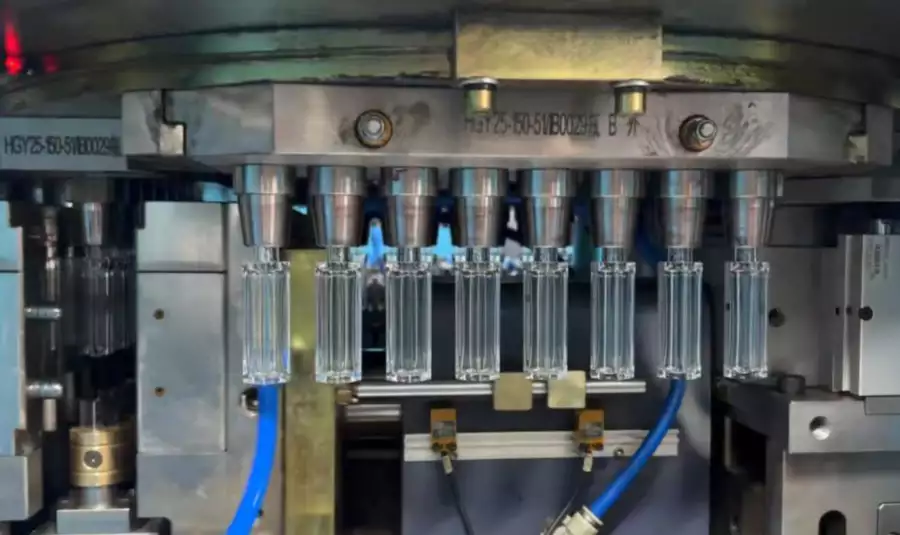

Figure 1: The Ever-power HGY50-V3-EV 3-Station Unit

Technical Specifications & Machine Parameters

In my experience, the reliability of an Injection Stretch Blow Molding Machine is defined by its components. The HGY50-V3-EV is built with top-tier global components to ensure 24/7 operation stability.

1. Technical Standard Configuration

| Component System | Specification / Brand |

|---|---|

| Servo Systems | 5 Sets (Inovance / MIRLE) |

| Servo Motor Power | 34.8 KW (Inovance / WEICHI) |

| PLC Control | Inovance / MIRLE |

| Turntable Rotation | Yaskawa Servo (Japan) / WEICHI Servo + TSUNTIEN Reducer (Taiwan) |

| High Pressure Valve | Parker (USA) |

| Pneumatic Cylinder | Airtak |

| Temperature Control | Integrated Box Control (High accuracy, stable) |

| Lead Screw | NSK (Japan) |

| Blow Molding Structure | Dual servo motor mold clamping with high-pressure compensation |

| Total Power | 45.2 KW |

2. Machine Parameters (HGY50-V3-EV)

| Parameter Item | Value / Description |

|---|---|

| Screw Diameter | 40mm (Optional) |

| Theoretical Injection Capacity | 239g |

| Injection Clamping Force | 50 KN |

| Blowing Clamping Force | 100 KN (Single Side) |

| Upper Mold Stroke | 280 mm |

| Lower Mold Stroke | 280 mm |

| Take-out Stroke | 150 mm |

| Blow Core Stroke | 100 mm |

| Blow Mold Stroke | 60 + 60 mm |

| Dimensions (L×W×H) | 3800 × 1200 × 2500 mm |

| Total Weight | 3.5 Tons |

3. Product Dimension Capabilities

| Product Quantity (Cavities) | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Bottle Diameter (mm) | 100 | 90 | 62 | 45 | 35 | 28 |

| Max. Bottle Volume (ml) | 2500 | 1500 | 900 | 400 | 250 | 100 |

| Max. Bottle Weight (g) | 130 | 65 | 43 | 32 | 26 | 22 |

| Neck Diameter (mm) | 60 | 38 | 30 | 27 | 20 | 17 |

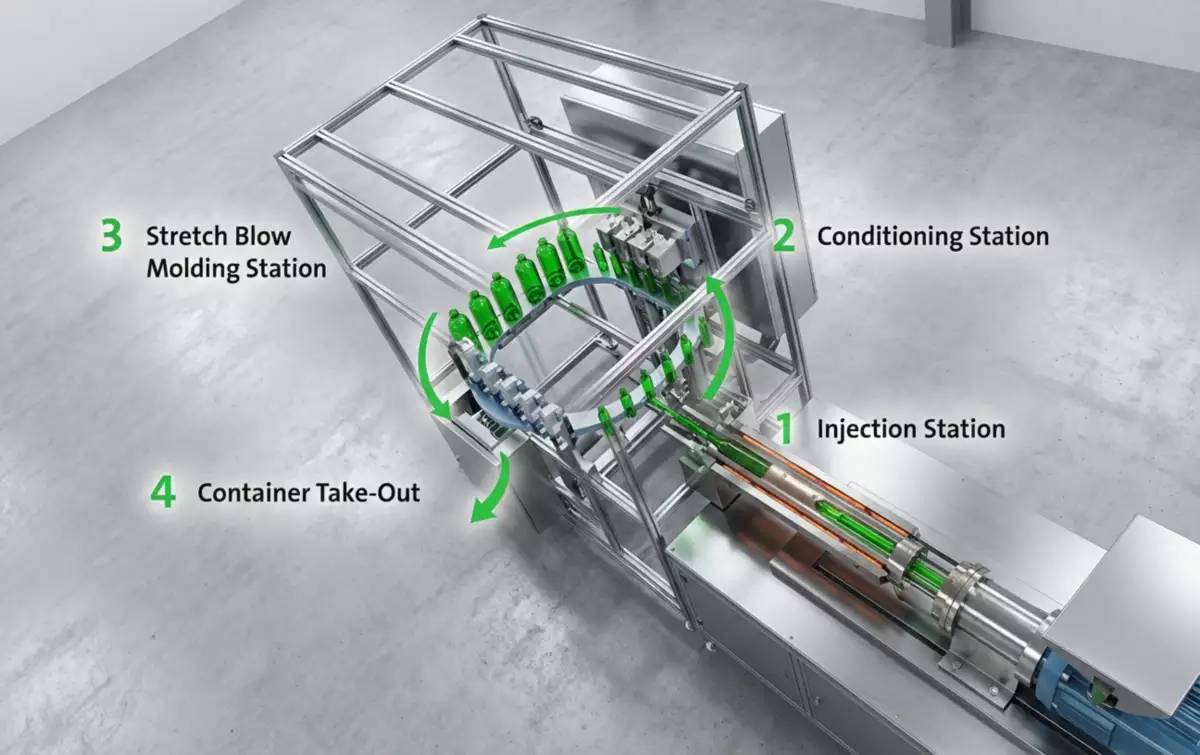

Core Technology: The One-Step ISBM Principle

The One Step PET Bottle Machine concept revolutionizes production by performing the entire bottle creation lifecycle on a single turntable index. This is crucial for materials like PETG, PC, and PCTG which are sensitive to reheating cycles.

Operational Process Flow

1. Injection Station

Molten resin is injected into the preform mold. The neck is formed to exact dimensions, and the body is cooled to a conditioned temperature suitable for stretching.

2. Conditioning (Thermal)

In our HGY50-V3-EV, temperature homogenization occurs during the transfer. The preform core is kept warm while the skin is cooled, creating the perfect thermal gradient for biaxial orientation.

3. Stretch & Blow Station

A stretch rod mechanically elongates the preform axially, while high-pressure air expands it radially. This biaxial stretching aligns the molecules for maximum strength.

4. Ejection Station

The finished container is stripped from the lip mold and automatically conveyed out. No manual intervention is required, ensuring hygiene.

Strategic Analysis: One-Step vs. Two-Step Systems

Why choose a One Step Injection Blow Molding system over the traditional two-step method? The answer lies in efficiency and quality control.

| Comparison Dimension | Ever-power One-Step ISBM | Traditional Two-Step (Reheat) |

|---|---|---|

| Process Flow | Resin to Bottle (Direct) | Resin -> Preform -> Storage -> Reheat -> Bottle |

| Energy Efficiency | High (Uses residual injection heat) | Low (Requires reheating cooled preforms) |

| Bottle Aesthetics | Perfect (No scratches, high gloss) | Risk of scratches during preform transport |

| Space Requirement | Compact (One machine) | Large (Injection machine + Blow machine + Storage) |

| Material Flexibility | Excellent (PET, PC, PP, PETG, Tritan) | Limited (Mostly standard PET) |

| Scrap Rate | Low (Integrated feedback loop) | Higher (Start-up losses in two machines) |

Core Technology Speed-Read: Why HGY50-V3-EV?

- ✓

Invisible Parting Lines: Our dual-servo clamping with high-pressure compensation ensures that cosmetic bottles have virtually invisible seams, a critical requirement for luxury brands. - ✓

Energy Dynamics: By integrating the One Step Injection Molding Machine logic, we utilize the “latent heat” of the plastic. You are not paying to heat the plastic twice. - ✓

Versatility: Whether it’s a specialized 10ml eye-drop vial or a wide-mouth peanut butter jar, the variable stroke and variable cavity capabilities make this machine a universal soldier in your factory.

Applied Industries & Product Capabilities

The ISBM Blow Molding Machine is the backbone of several high-hygiene and high-aesthetic sectors.

Pharmaceuticals & Medical

Perfect for producing eye drop bottles, pill bottles, and vaccine vials. The “one-step” nature means the bottle neck is never touched after injection, ensuring ISO-class hygiene.

Cosmetics & Personal Care

Heavy-wall jars, mascara containers, and lotion bottles requiring glass-like clarity without the weight and breakage risk of glass.

Baby Care

Ideal for PPSU and PC baby feeding bottles. The machine handles high-temperature engineering plastics with ease.

Food & Beverage

Wide-mouth jars, condiment bottles, and mini-liquor bottles. The precise neck finish ensures perfect cap sealing every time.

Market Position & Investment Return Analysis

Benchmarking: Ever-power vs. Japanese Counterparts

We respect the pioneers like ASB and Aoki. However, Ever-power offers a distinct value proposition: 95% of the performance at 60% of the investment cost.

| Feature | Ever-power HGY50-V3-EV | Leading Japanese Brand (ASB/Aoki) |

|---|---|---|

| Core Components | Same Global Top Tier (Yaskawa, Parker, NSK) | Proprietary + Global Top Tier |

| Cycle Time | ~8-12 seconds (Product dependent) | ~8-12 seconds |

| After-Sales Service | Remote + Local Partners (Fast Response) | Global Network (High Cost) |

| ROI Period | 12 – 18 Months | 36 – 48 Months |

ROI Projection: Medium Beverage Plant Case

Switching to an One Step Blow Molding Equipment setup allows you to stop buying preforms. For a plant producing 10 million bottles/year:

- Material Savings: Buying resin pellets vs. preforms saves approx. 20-30% in raw material costs.

- Energy Savings: Eliminating the reheat tunnel saves approx. 40% on electricity bills compared to 2-step.

- Logistics: Zero warehouse space needed for preform storage.

[North America] Extreme Climate Resilience & Local Compliance

For our clients in varying climates, from the humidity of Southeast Asia to the dry winters of Canada, the HGY50-V3-EV features a closed-loop hydraulic oil temperature stabilization system. This ensures that the “start-up” consistency is maintained regardless of ambient temperature.

Compliance: The machine is fully CE compliant for the European market and meets UL standards for electrical safety in North America. We provide full documentation for local safety audits.

Engineer’s Corner: Frequently Asked Questions

Can this machine process recycled PET (rPET)?

Yes, the plasticizing screw is specially coated to handle the slightly different melt flow index of rPET. However, the material must be thoroughly dried and dehumidified before processing.

What is the mold changeover time?

For a skilled technician, a complete mold change (Injection + Blow + Lip molds) takes approximately 2 to 3 hours. The quick-change design of the HGY50-V3-EV facilitates this.

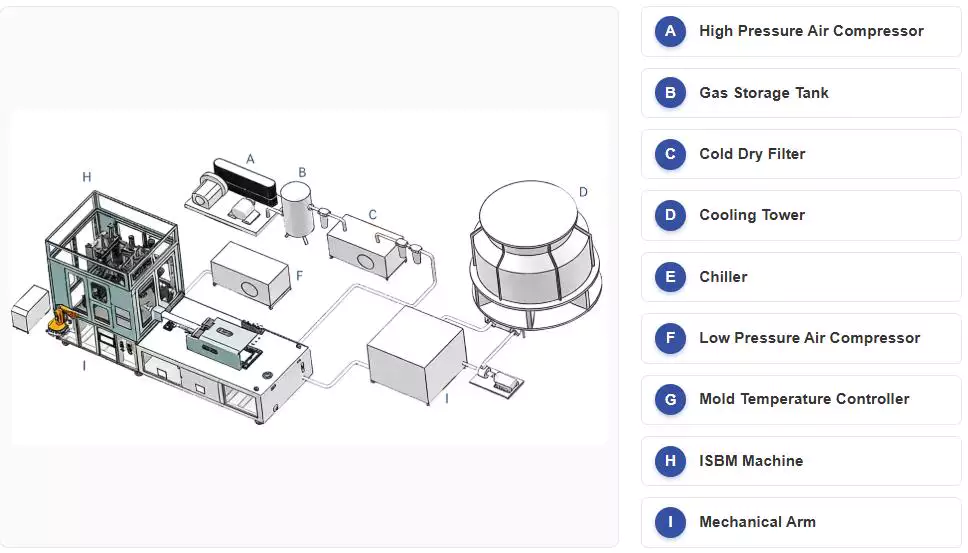

Does it require a chiller?

Yes, consistent mold cooling is critical for cycle time and clarity. We recommend a 10HP-15HP chiller depending on your ambient temperature.

How does the 3-station design handle conditioning?

The 3-station design (Injection, Stretch-Blow, Eject) manages conditioning primarily in the injection mold and during the turntable transfer. By precise control of the injection mold cooling time, we deliver the preform to the blow station at the exact orientation temperature.

Global Field Notes: Real Client Stories

From my notebook to your screen—real deployments of the Injection Blow Molding Machine (One Step).

USA: Pharmaceutical Vials

“We replaced 3 older machines with one HGY50. The cleanroom footprint reduction was massive.” – Ops Manager, Ohio

Brazil: Cosmetic Jars

“The servo control on the injection stage solved our wall thickness consistency issues.” – Production Lead, São Paulo

Germany: Bio-Polymers

“Processing PLA was tricky, but Ever-power’s temperature control system made it stable.” – R&D Director, Munich

Indonesia: Beverage

“High humidity usually affects PET, but the closed conditioning on this machine works wonders.” – Plant Manager, Jakarta

Swipe to view more global success stories

Complete Your Production Line

A clean air source is vital for blow molding. We also manufacture high-efficiency oil-free air compressors designed specifically to pair with our ISBM units, ensuring no oil contamination reaches your sterile bottles.

Ready to Upgrade Your Bottle Production?

Stop compromising with reheating preforms. Step into the future of “Resin-to-Bottle” manufacturing with the HGY50-V3-EV. Let’s discuss your bottle geometry and cycle time goals.

Ever-power Machinery | Expert Engineering for 20 Years