Description

One Step Injection Stretch Blow Molding Machine HGY250-V4: The ASB-70DPH Compatible Industrial Standard

Engineered by Ever-power | 4-Station High Precision | 300KN Injection Clamping Force

Engineering Overview: Maximizing Legacy Tooling Value

In the specialized world of polymer processing, the debate between upgrading machinery and preserving tooling assets is constant. As a mechanical engineer with two decades dedicated to One Step Blow Molding Machine technology, I have seen too many factories scrap perfectly good molds because they couldn’t find compatible modern machinery. The HGY250-V4 is Ever-power’s answer to this industry-wide challenge. It is a heavy-duty, 4-station ISBM unit designed with a singular strategic advantage: direct compatibility with ASB-70DPH molds.

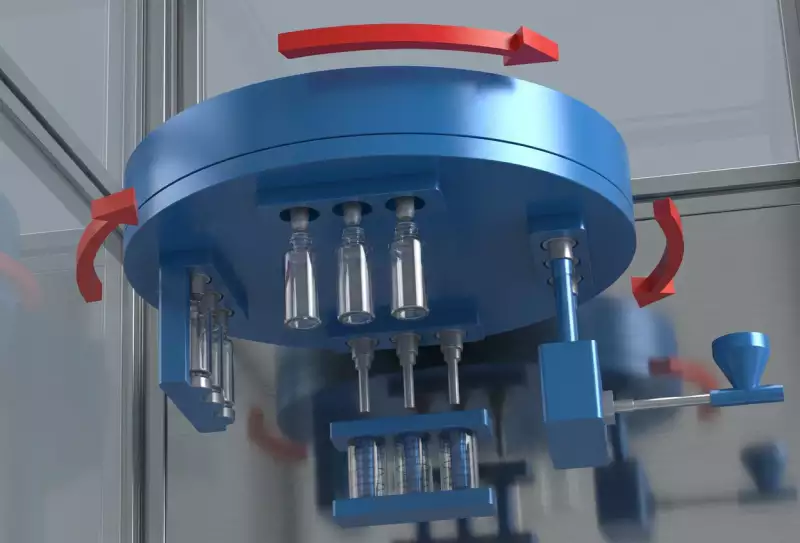

This machine is not merely a retrofit solution; it is a performance upgrade. Operating on a robust 4-station rotary indexing system (Injection, Temperature Conditioning, Stretch-Blow, Ejection), the HGY250-V4 ensures optimal thermal history for PET and PETG resins. With a massive 300KN Injection Clamping Force and a reinforced 200KN Blowing Clamping Force, it effortlessly handles high-cavitation setups (up to 14 cavities) and heavy-wall containers that lesser machines fail to mold consistently. For manufacturers in the cosmetic and pharmaceutical sectors, this is the most logical path to expanding capacity while leveraging your existing high-value Japanese tooling inventory.

Figure 1: The Ever-power HGY250-V4 Heavy Duty 4-Station Unit

1. Technical Standard Configuration

The reliability of an ISBM Machine is dictated by its weakest component. We eliminate weak points by integrating top-tier global components, ensuring the HGY250-V4 delivers 24/7 stability comparable to its Japanese counterparts.

| System / Component | Brand / Specification |

|---|---|

| Servo System | 3 sets of servo pump systems |

| Servo Motor Power | 67.7KW (Inovance / WEICHI) |

| Control System (PLC) | Inovance / MIRLE (High-speed logic processing) |

| Turntable Rotation | Yaskawa Servo (Japan) or WEICHI Servo + TSUNTIEN Reducer (Taiwan) |

| Blow Molding Structure | Hydraulic cylinder or Dual servo motor mold damping system with high-pressure compensation |

| High Pressure Valve | Parker (USA) |

| Pneumatic Cylinder | Airtak (Germany/Taiwan Technology) |

| Temperature Control | Integrated Control Box (High accuracy for consistent viscosity) |

| Hydraulic Control | YUKEN (Taiwan) Pressure Control Valve |

| Screw Heating | Nano-far-infrared energy-saving heating ring (10KW) |

| Injection Unit Control | Single cylinder control (Hydraulic or Servo Melt Motor options) |

| Mold Compatibility | Compatible with ASB-70DPH mould |

| Total Power | 82.7 KW |

2. Machine Parameters: Heavy Duty Capabilities

The HGY250-V4 is designed for high-tonnage applications. The 300KN clamping force is a critical feature for minimizing flash on large-surface-area preforms.

| Parameter | Value |

|---|---|

| Screw Diameter | 55mm (Standard) / Options: 50, 60mm |

| Theoretical Injection Capacity | 420g (Range: 340 – 480 cm³) |

| Injection Clamping Force | 300 KN |

| Blowing Clamping Force | 200 KN |

| Upper Mold Stroke | 640 mm |

| Lower Mold Stroke | 350 mm |

| Temp. Regulating Core Stroke | 300 mm |

| Temp. Regulating Barrel Stroke | 300 mm |

| Take-out Stroke | 190 mm |

| Blow Core Stroke | 300 mm |

| Blow Mold Stroke | 75 + 75 mm |

| Oil Tank Volume | 600 L |

| Machine Dimensions (L*W*H) | 6300 x 2400 x 3700 mm |

| Machine Weight | 16 Tons |

Production Capacity: Cavity & Dimension Matrix

| Product Quantity (Cavities) | 2 | 3 | 4 | 5 | 6 | 8 | 9 | 10 | 14 |

|---|---|---|---|---|---|---|---|---|---|

| Max Bottle Diameter (mm) | 200 | 160 | 120 | 80 | 60 | 45 | 40 | 40 | 30 |

| Max Bottle Height (mm) | 220 | 180 | 100 | ||||||

| Neck Diameter (mm) | 130 | 130 | 100 | 65 | 55 | 40 | 32 | 28 | 16 |

| Max Bottle Volume (ml) | 2500 | 1500 | 900 | 750 | 350 | 200 | 100 | 50 | 30 |

| Max Bottle Weight (g) | 200 | 180 | 150 | 120 | 80 | 60 | 50 | 35 | 25 |

Core Technology: 4-Station ISBM Process Flow

The One Step Injection Blow Molding technology used in the HGY250-V4 is a masterclass in thermal management. By using a rotary table to move the cores between four distinct stations, we ensure the PET retains its Intrinsic Viscosity (IV) for maximum strength and clarity, without the energy loss of reheating.

1. Injection Station

Molten PET is injected into the cavity. The 300KN clamping force ensures no flash on the parting lines, even with high-pressure injection required for thin-wall preforms or complex necks.

2. Conditioning Station

The V4 Advantage: The preform is transferred to a conditioning pot. This station homogenizes the temperature—cooling the skin or heating the core—creating the perfect thermal gradient for stretching.

3. Stretch & Blow

A stretch rod extends the preform axially, followed by high-pressure air expanding it radially. The 200KN Blow Clamping Force ensures the mold remains perfectly closed during high-pressure expansion.

4. Ejection

The finished bottle is stripped from the lip mold and automatically conveyed out. The process is touchless, ensuring hygiene for pharmaceutical applications.

Why Choose the HGY250-V4? Core Advantages

- ✓

ASB-70DPH Compatibility: The platen design, tie-bar spacing, and ejection strokes are engineered to accept existing ASB-70DPH molds. This saves you tens of thousands of dollars in re-tooling costs. - ✓

High-Tonnage Stability: With a 16-ton machine weight and 300KN clamping force, vibration is non-existent, leading to superior bottle reproducibility and longer mold life. - ✓

Energy Dynamics: We use Nano-far-infrared heating rings (10KW) which penetrate the barrel deeper and faster than standard ceramic heaters, saving ~30% on heating costs. - ✓

High Cavitation Capability: Capable of running up to 14 cavities for small vials, drastically increasing output per cycle compared to standard 4-8 cavity machines.

Strategic Analysis: One-Step vs. Two-Step Systems

| Comparison Dimension | Ever-power One-Step ISBM | Traditional Two-Step (Reheat) |

|---|---|---|

| Process Flow | Resin -> Bottle (Integrated) | Resin -> Preform -> Cool -> Reheat -> Bottle |

| Energy Efficiency | High (Uses latent injection heat) | Low (Wastes energy reheating preforms) |

| Surface Quality | Flawless (No scuffing/scratches) | Risk of transport scratches on preforms |

| Applicable Materials | PET, PETG, PC, Tritan, PPSU, PP | Mostly limited to PET/PP |

| Space Requirement | Compact (One machine) | Large (Requires Injection unit + Blow unit + Storage) |

| Hygiene Level | Medical/Food Grade (Touchless) | Standard (Exposed to open air storage) |

Industry Applications

High-End Cosmetics

The One Step PET Bottle Machine excels in producing heavy-wall cream jars and mascara containers. The high clamping force ensures the thick bases are molded without sink marks.

Pharmaceuticals

From eye drops to wide-mouth pill bottles, the HGY250-V4 ensures neck precision for child-resistant caps. The enclosed process meets strict GMP requirements.

Baby Care (PPSU/PC)

The machine’s robust screw and heating system are perfect for processing high-temperature engineering plastics like PPSU for baby bottles, which require high injection pressure.

Power System Selection Summary: Ever-power vs. Competitors

Many clients ask how we compare to Japanese giants like ASB or Aoki. The answer is simple: We offer 95% of the capability at 60% of the cost.

The Ever-power Guarantee: Our HGY250-V4 is built with the same global components (Yaskawa, Parker, NSK) found in more expensive machines. We don’t cut corners on hardware; we optimize manufacturing overhead to pass savings to you.

ROI Case: Cosmetic Jar Manufacturer

Switching from purchasing preforms to an in-house One Step Blow Molding Equipment setup:

- Tooling Savings: Using your existing ASB-70DPH molds means instant production start-up with zero new mold costs.

- Material Savings: Pellet cost is ~25% lower than preform cost.

- Payback Period: Typically 12-18 months for a single HGY250-V4 unit due to high output capacity (up to 14 cavities).

[North America] Extreme Condition Resilience

For our clients in varying climates, the HGY250-V4 is equipped with an advanced hydraulic oil cooling loop. Whether you are operating in the humid summers of Florida or the freezing winters of Minnesota, the system maintains a stable oil temperature of 40-50°C, ensuring consistent clamp pressure and cycle times.

Compliance: CE Certified, UL Electrical Standards compliant upon request.

Engineer’s FAQ

Can I use my existing ASB-70DPH molds directly?

Yes, absolutely. The HGY250-V4 is engineered with the same platen layout and mounting points. You can transfer your legacy molds directly to our machine.

What is the max bottle size for this machine?

In a 2-cavity configuration, it can produce bottles up to 2.5 Liters (200mm diameter). In a 14-cavity setup, it is optimized for small vials up to 30ml.

What is the maintenance schedule?

We recommend a hydraulic oil change every 5,000 hours and a daily check of the lubrication points. The auto-lube system handles most moving parts.

Global Case Studies: Engineer Field Notes

USA: Pharmaceutical Vials

“Replaced 3 older units. The cleanroom footprint reduction was massive.” – Production Manager, NJ

Brazil: Premium Cosmetics

“The conditioning station allows us to mold heavy-bottom jars without defects.” – Plant Lead, São Paulo

Germany: Bio-resins

“Handling PLA was difficult until we tried the V4’s precise temp control.” – Engineer, Munich

India: Baby Bottles

“Producing PPSU baby bottles requires high heat. The V4 handles it perfectly.” – Director, Mumbai

Vietnam: Beverage

“Reliable output in a hot climate. The oil cooling is robust.” – Tech Lead, Hanoi

Swipe to view more client success stories

Complete Your Production Line

Ensure contamination-free air for your blowing process with our specialized Oil-Free Air Compressor.

Ready to Upgrade Your Production?

Don’t let outdated machinery hold you back. Experience the precision of the HGY250-V4 and see why global manufacturers trust Ever-power.